Device and method for increasing utilization rate of starting cage bar of permanent magnet motor

A technology of permanent magnet motor and utilization rate, which is applied in electromechanical devices, synchronous machines, electrical components, etc., can solve the problems of reducing the utilization rate of starting cages, and achieve the effects of shortening start-up time, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

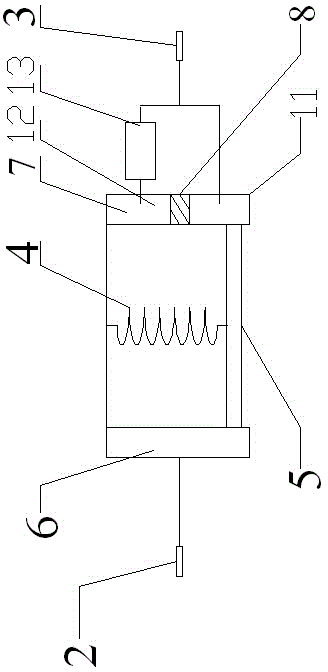

[0027] Such as image 3 As shown, the right slide rail 7 is provided with a first conductive block 11 and a second conductive block 12 from bottom to top, the first conductive block 11 is connected to the second half section 3 of the starting cage, and the second conductive block 12 is connected to It is connected with the second half section 3 of the starting cage, and the second conductive block 12 is connected with the S pole of the first thyristor 13. When the motor reaches a medium speed after starting, the centrifugal force received by the conductive slide plate 5 is greater than the elastic force of the spring 4, and the two ends of the conductive slide plate 5 Respectively move upwards in the left slide rail 6 and the right slide rail 7, the conductive slider 5 is connected with the second conductive block 12, and the first thyristor 13 limits the direction of the current in the starting cage so that the direction of the eddy current generated by the starting cage ...

Embodiment 2

[0029] Such as Figure 4 As shown, with reference to Embodiment 1, the right slide rail 7 is provided with a first conductive block 11 and a second conductive block 12 from bottom to top, the first conductive block 11 is connected with the second half of the starting cage 3 through a resistor 14, and the second The conductive block 12 is connected to the second half of the starting cage 3 through the first thyristor 13, and the second conductive block 12 is connected to the S pole of the first thyristor 13. When the motor is ready to start or rotate at a low speed, the conductive slide 5 and the first conductive block 11 Connected, the resistor 14 reduces the current in the starter cage, so that the motor can get a larger starting torque.

Embodiment 3

[0031] Such as Figure 5 As shown, referring to Embodiment 2, the right slide rail 7 is provided with a first conductive block 11, a second conductive block 12 and a third conductive block 15 from bottom to top, and the first conductive block 11 communicates with the rear half of the starting cage through a resistor 14. Section 3 is connected, the second conductive block 12 is connected to the second half of the starting cage bar 3 through the first thyristor 13, the second conductive block 12 is connected to the S pole of the first thyristor 13, and the third conductive block 15 is directly connected to the second half of the starting cage bar Section 3 is connected. When the motor reaches high-speed operation, the conductive slide plate 5 moves upward under the action of centrifugal force and connects with the third conductive block 15. Since the excitation performance of the ferrite permanent magnet rotor 1 is poor, the motor achieves a weak magnetic field increase at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com