Preparation method and application of carbon nitride-titanium dioxide heterojunction material for efficiently synthesizing ammonia through visible light

A technology of titanium dioxide and carbon nitride, which is applied in the field of nanomaterials and photocatalysis, can solve the problems of low utilization rate of photogenerated carriers, recombination of photogenerated electrons and holes, etc., to solve the problems of low charge utilization rate, poor adsorption capacity, Migration-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Synthesis of Carbon Nitride Nanosheets

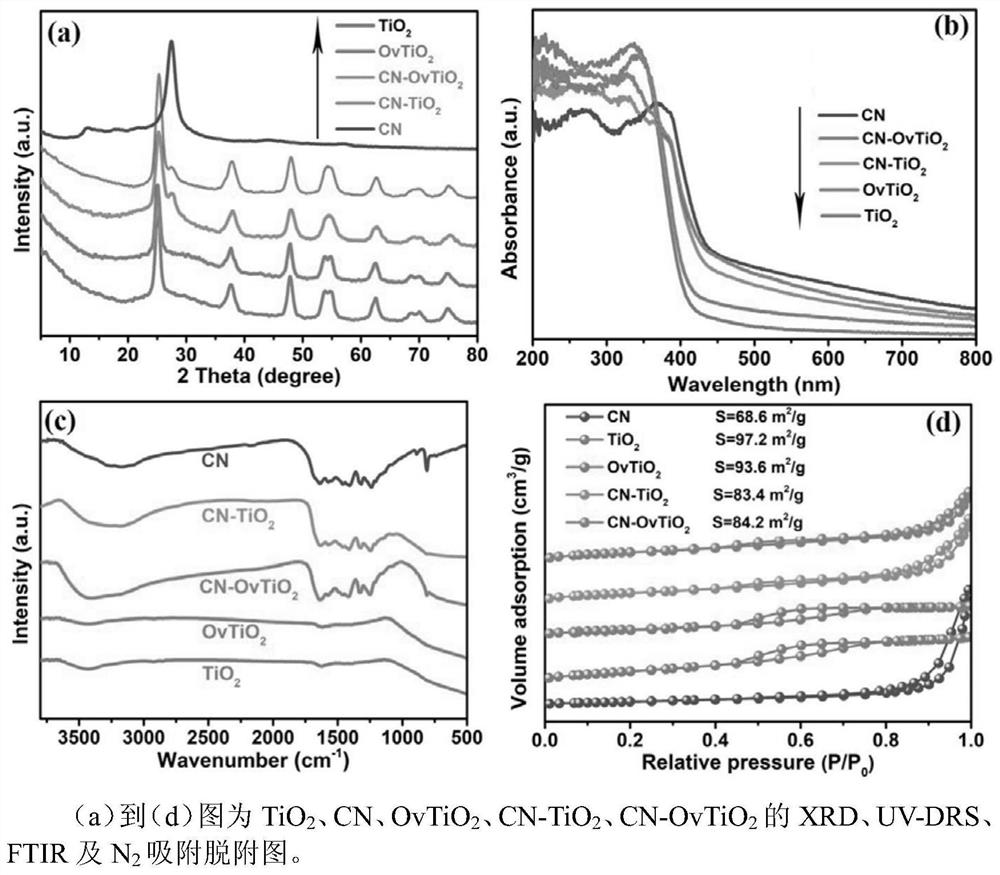

[0024] Put 2 g of urea evenly in the porcelain ark, place the porcelain ark in the air atmosphere of the muffle furnace and calcinate for 4 hours, the calcining temperature is 530°C, the heating rate is 2.3°C per minute, and the calcined product is ground into powder That is, carbon nitride nanosheets (CN) are obtained.

Embodiment 2

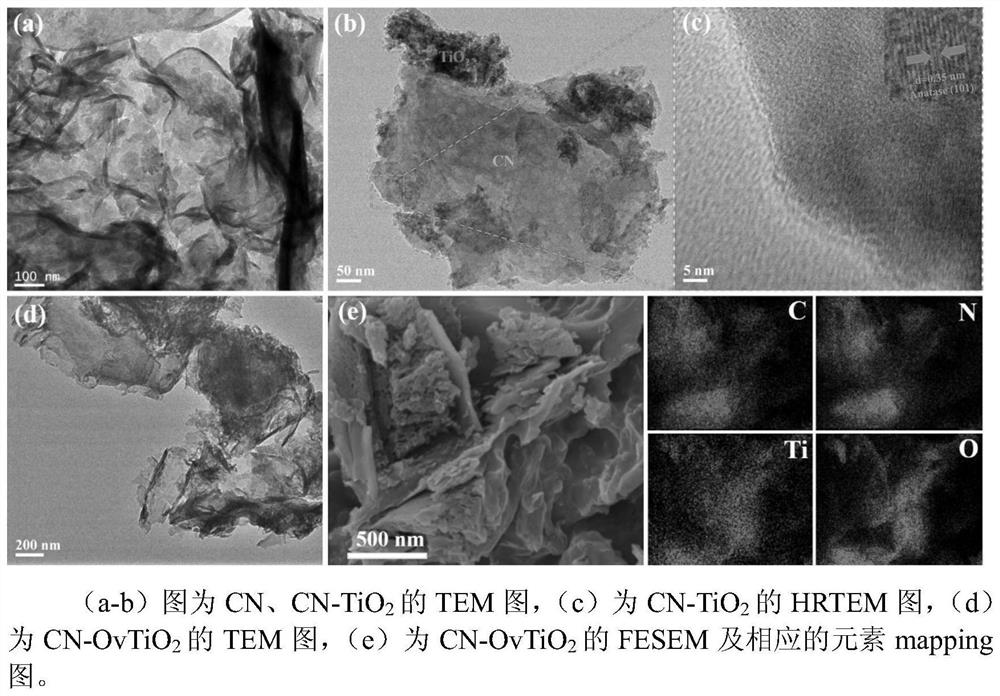

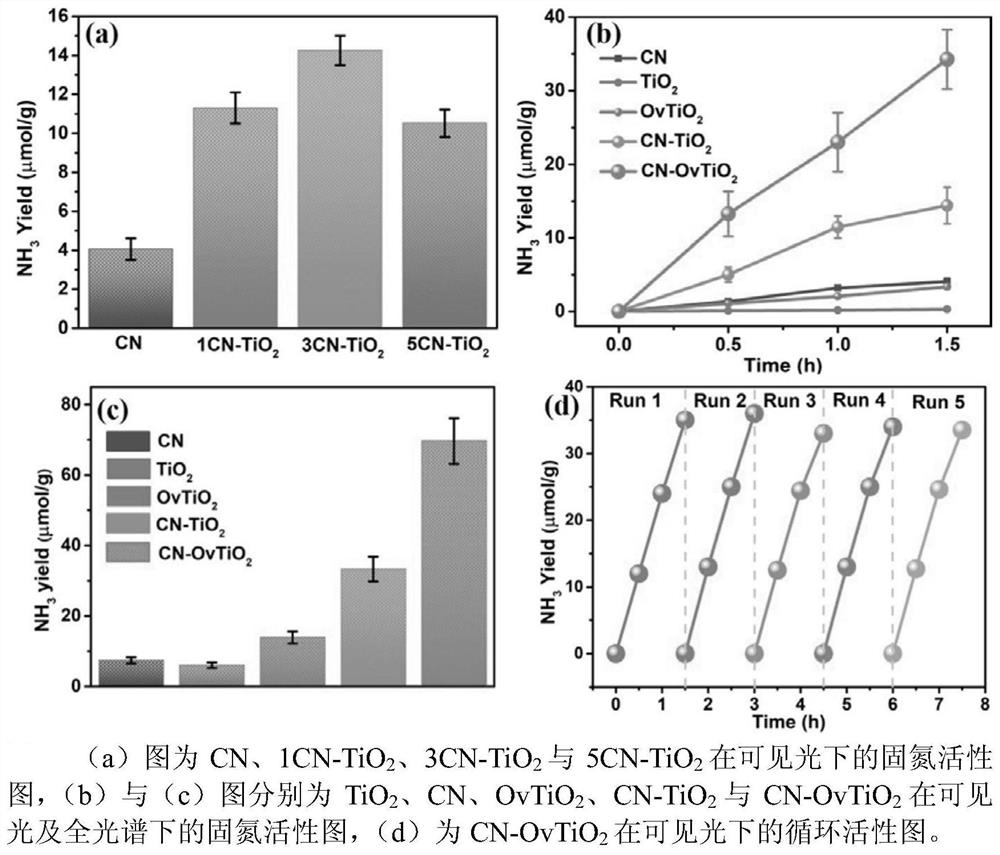

[0026] Synthesis of Carbon Nitride-TiO2 Heterojunction

[0027] 0.13 mL TiCl 4 Slowly add 7.5 mL of ethanol containing different amounts (100 mg, 300 mg, 500 mg) of CN dropwise, stir for 10 minutes, then add 0.8 mL of isopropyl titanate dropwise, and continue stirring for 2 hours to obtain a uniform solution. Place the above solution in a constant temperature and humidity box for 2 days at a temperature of 40°C and a humidity of 55%, then put it in a 70°C oven for aging for 1 day, and finally place it in a muffle furnace for calcination at 400°C for 8 hours, with a heating rate of 2°C / min, the obtained sample is a carbon nitride-titanium dioxide heterojunction (CN-TiO 2 ).

Embodiment 3

[0029] Synthesis of Carbon Nitride-TiO2 Heterojunction Rich in Oxygen Vacancies

[0030] The prepared carbon nitride-titanium dioxide heterojunction was placed in a tube furnace and calcined for 4 hours under an argon atmosphere. The calcination temperature was 300°C and the heating rate was 1°C / min. The obtained sample was rich in oxygen vacancies. The carbon nitride-titanium dioxide heterojunction (CN-OvTiO 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com