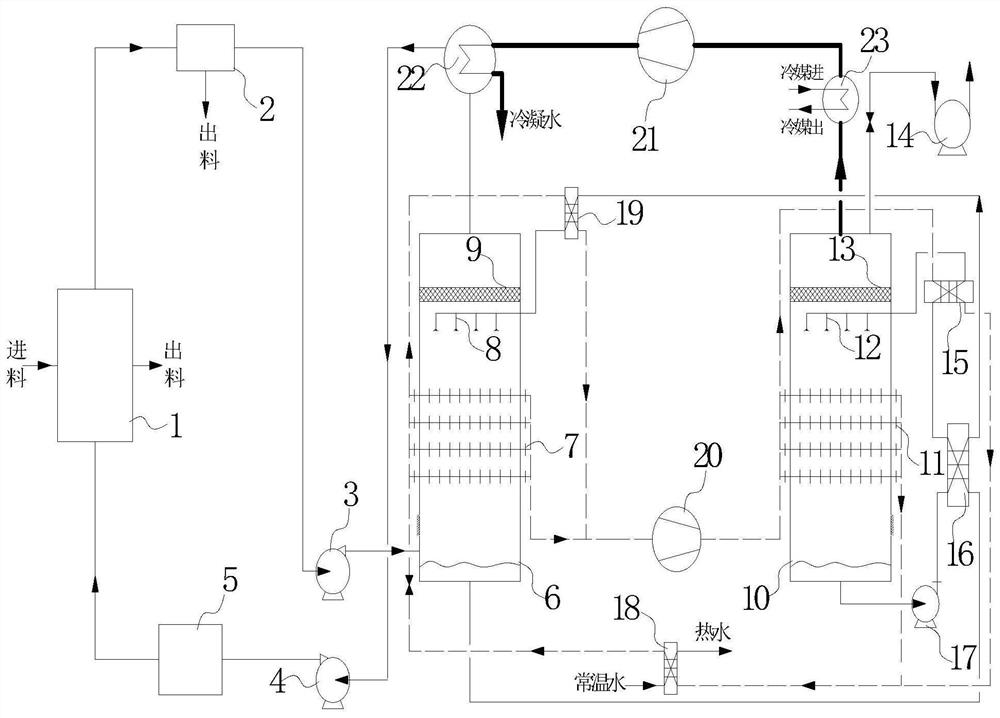

A closed cycle drying system coupled with open absorption heat pump and MVR technology

An absorption heat pump and closed-circuit cycle technology, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems that it is difficult to meet the needs of high-temperature heating and low-grade water vapor, so as to improve energy utilization rate, Effects of stable regeneration process and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this example, air is used as a dry medium, and the moisture containing water content of 18.3% is dried to a water content of 0.55%, and the amount of feed of wet materials is 1000 kg / h. The air temperature required for the dryer is 130 ° C. Hoate content is 10.7g / kg (绝干气) The flow rate is 3423kg / h, the wet air temperature of the exit is 60 ° C, the moisture content is 63.4 g / kg (绝干气) . The absorbent salt solution is selected from 65% LiBr aqueous LiBr solution. The water supply temperature of the absorber is 60 ° C. The mass flow ratio of the concentrated solution of the absorber and the mass flow ratio of the hot and moisture exhaust gas is 0.475. After the absorption process is completed, the absorber is completed. The concentration of the bottom salt solution becomes 58.9%, the temperature is maintained at 60 ° C, and the top air outlet temperature of the absorber is 60 ° C, the humidity is 10.7 g / kg. (绝干气) The pressure is 101.3 kPa.

[0040] The mechanical ...

Embodiment 2

[0045] In this embodiment, air is used as a medium, and the moisture content of 48% is lowered by spray drying to 3.1%, and the amount of feed material is 1000 kg / h, and the intake temperature of the dryer is 240 ° C, and humidity 11.7g / kg (绝干气) The flow rate is 12113kg / h, the wet air temperature of the exit is 75 ° C, the moisture content is 50.4 g / kg. (绝干气) . The moisture absorbent salt solution is selected from 65% LiBr aqueous LiBr solution, and the water supply temperature of the absorber is 60 ° C. The mass flow ratio of the concentrated solution of the absorber is 0.144, and after the absorption process is completed, the absorber is completed. The concentration of the bottom salt solution becomes 51.8%, the temperature is maintained at 60 ° C, and the top air outlet temperature of the absorber is 60 ° C, the humidity is 11.7 g / kg. (绝干气), The pressure is 101.3 kPa.

[0046] The mechanical compression heat pump circulation system employs a high temperature solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com