Coordinated driving type multi degree-of-freedom ultrasonic motor based on spherical hinge structure and working method of motor

A technology of ultrasonic motor and degree of freedom, applied in the direction of piezoelectric effect/electrostriction or magnetostriction motor, generator/motor, electrical components, etc., can solve the problem of no pre-pressure application method, etc., to solve the problem of pre-pressure Difficult to adjust, large thrust-to-weight ratio, and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

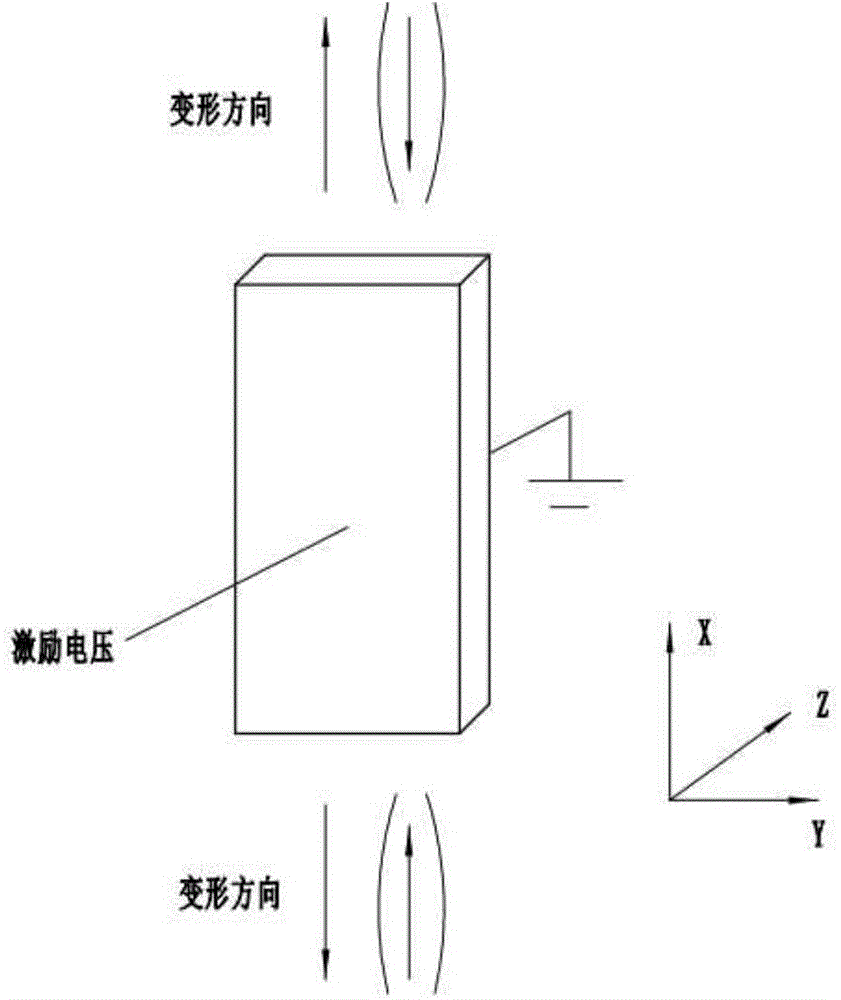

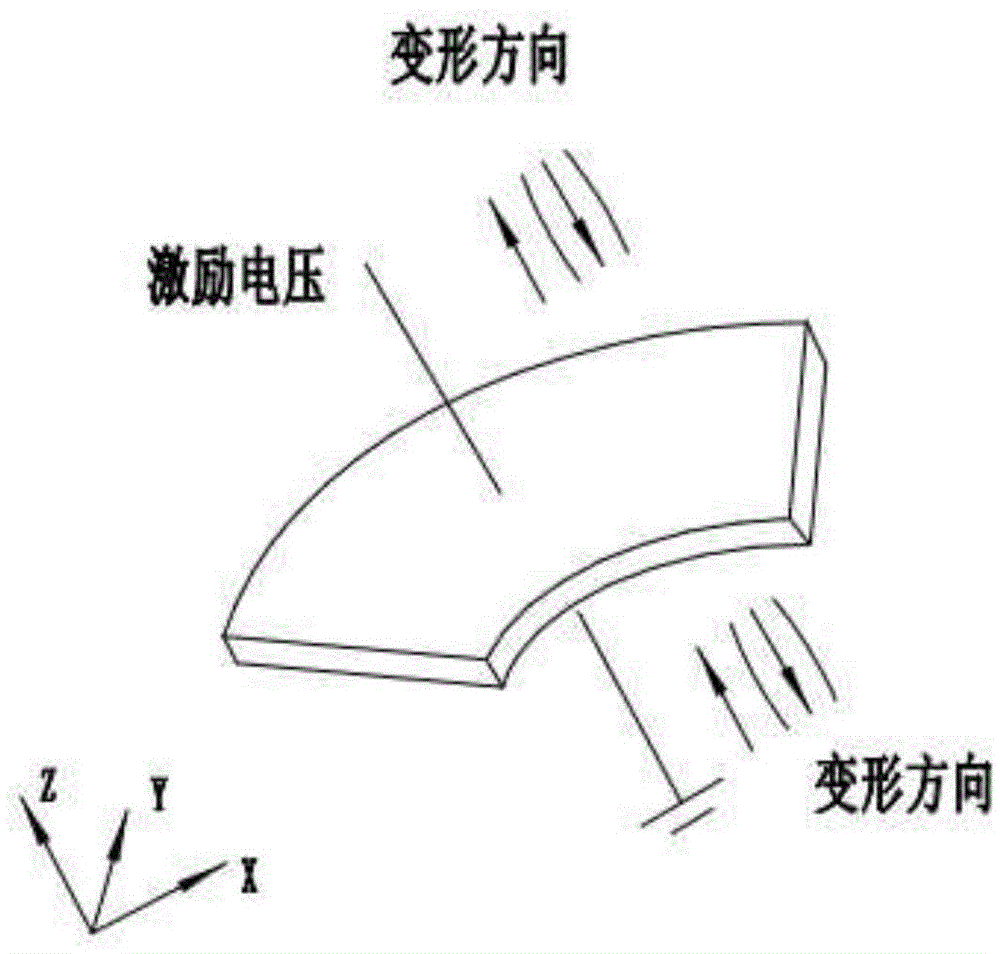

[0028] The inverse piezoelectric effect of piezoelectric ceramics refers to the phenomenon of mechanical deformation caused by applying an electric field to piezoelectric ceramics. According to different polarization modes of piezoelectric ceramics, the corresponding ways of inducing deformation are also different, and the present invention is based on the spherical hinge structure. The coordinated driving multi-degree-of-freedom ultrasonic motor utilizes the d31 effect of square piezoelectric ceramics and the d33 effect of ring piezoelectric ceramics. Let the directions corresponding to the x, y, and z coordinate axes be 1, 2, and 3, respectively. The d31 effect means that the electric field is applied along the polarization direction 3, and the induced strain is along the 1 direction, as shown in Fig. 1(a). The excitation voltage is applied later, and the mechanical deformation of elongation (shortening) is generated on the upper and lower sides; the d33 effect refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com