Power-consumption-free starter for commercial refrigeration compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

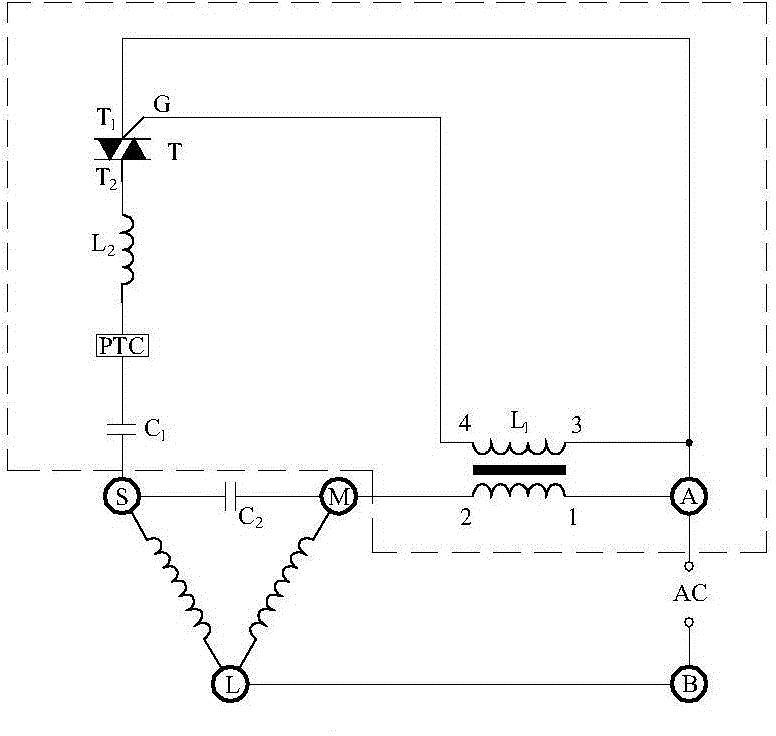

Embodiment 1

[0021] see figure 1 , a kind of non-power consumption starter that commercial refrigeration compressor motor is used, and described compressor motor has the stator that is made of at least one main winding and an auxiliary winding, and the lead-out end of the main winding of the motor is set as M, and the lead-out end of the auxiliary winding of the motor Set it as S, set the lead-out end of the combination of the main and auxiliary windings of the motor as L; set the two external connection terminals of the external AC power supply AC corresponding to the compressor motor as A-side and B-side respectively, and A-side and B-side can be interchanged. The motor starter includes a current transformer L1, a triac T, an inductor L2, a PTC element and a starting capacitor C1, and the current transformer L1, a triac T, an inductor L2 and a starting capacitor C1 are all conventional components. The PTC element is a PTC thermistor, specifically, it can be composed of a PTC thermistor ...

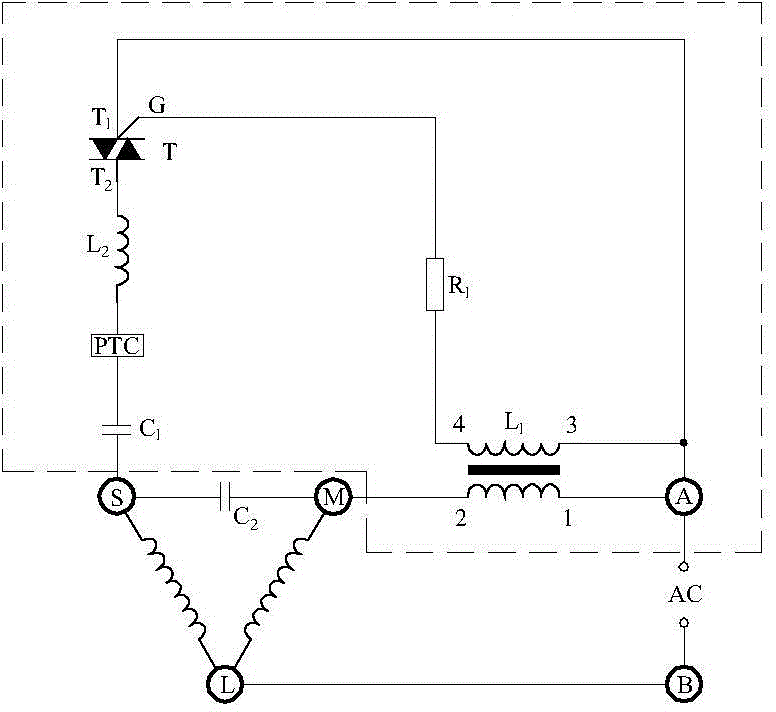

Embodiment 2

[0024] see figure 2 , in the motor starter described in Embodiment 1, a first resistor R1 is added. One end of the first resistor R1 is connected to the terminal 4 of the current transformer L1, and the other end of the first resistor R1 is connected to the G pole of the triac T. By selecting appropriate parameters of the current transformer L1 and the first resistor R1, the induced current in the secondary coil of the current transformer L1 can be sufficient to trigger the triac T. The first resistor R1 is a current limiting resistor.

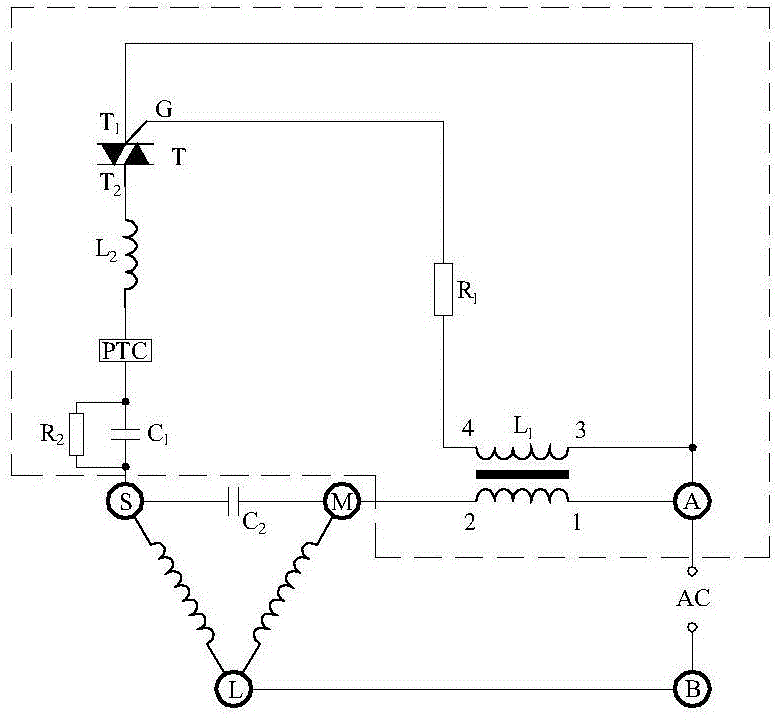

Embodiment 3

[0026] see image 3 In the motor starter described in Embodiment 2, a second resistor R2 is added, and the second resistor R2 is connected in parallel to both ends of the starting capacitor C1. The second resistor R2 is a discharge resistor, which is used to shunt the current flowing in the starting capacitor C1 and also play the role of anti-interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com