Zero-radiation high-efficient electric heating energy converter

An energy converter and zero-radiation technology, applied in the direction of induction heating, can solve the problems of energy loss, low space utilization, large volume, etc., and achieve the effects of increased space utilization, high electrothermal conversion efficiency, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

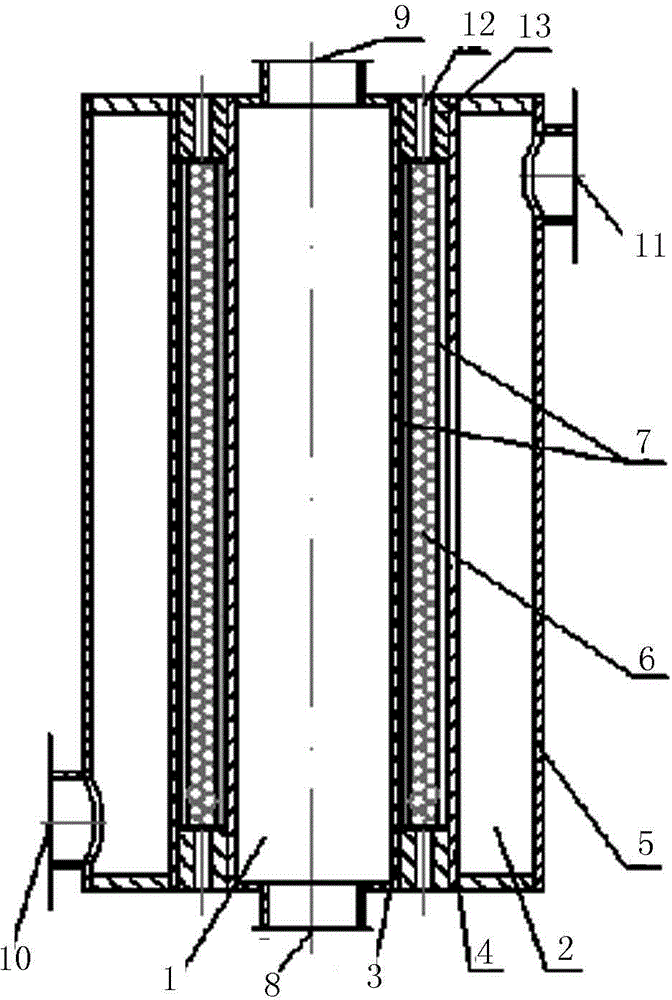

[0025] Such as figure 1 As shown, the present invention is a zero-radiation high-efficiency electrothermal energy converter, which is a vertical structure, and it includes a heating inner cavity 1 and a heating outer cavity 2, and the heating inner cavity 1 and the heating outer cavity 2 constitute the electrothermal energy for the heat transfer medium Conversion, the heating inner cavity 1 is formed by sealing the inner wall of the inner cavity heating tube 3, and the inner cavity heating tube 3 is a cylindrical shape surrounded by iron-based stainless steel or other iron-based metal materials, and the heating inner cavity heat transfer medium inlet 8 is set at The lower end of the inner cavity heating tube 3, the heating inner cavity heat transfer medium outlet 9 is arranged on the upper end of the inner heating cavity 3, the heating outer cavity 2 is formed by sealing the outer wall of the outer cavity heating tube 4 and the inner wall of the outer casing 5, and the outer ca...

Embodiment 2

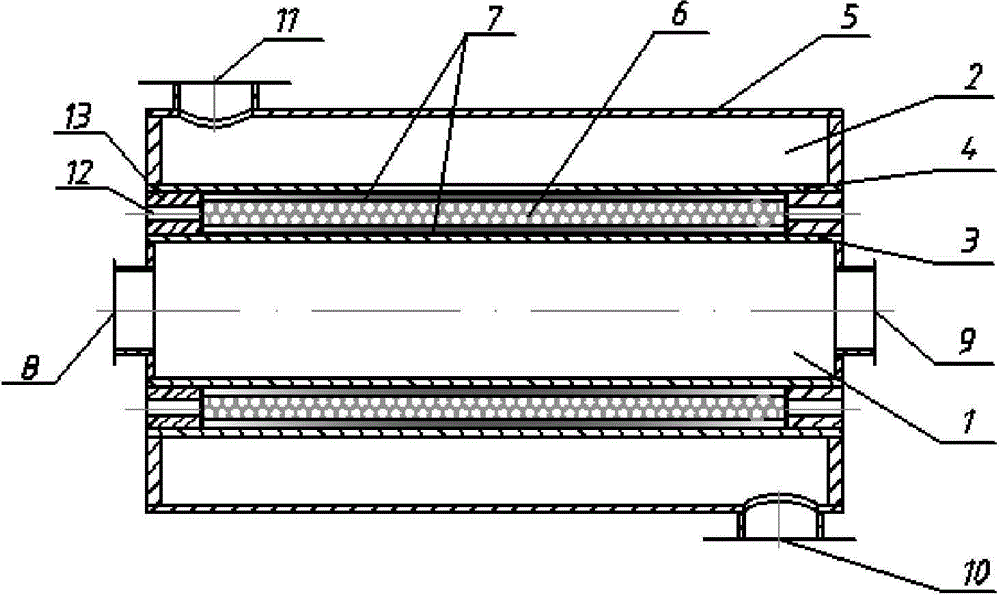

[0027] Such as figure 2 As shown, the present invention is a zero-radiation high-efficiency electrothermal energy converter, which is a horizontal structure, and it includes a heating inner cavity 1 and a heating outer cavity 2, and the heating inner cavity 1 and the heating outer cavity 2 constitute the electrothermal energy for the heat transfer medium Conversion, the heating inner cavity 1 is formed by sealing the inner wall of the inner cavity heating tube 3, and the inner cavity heating tube 3 is a cylindrical shape surrounded by iron-based stainless steel or other iron-based metal materials, and the heating inner cavity heat transfer medium inlet 8 is set at The side end of the inner cavity heating tube 3, the heat conduction medium outlet 9 of the heating inner cavity is arranged at the other end of the inner heating cavity 3, and the heating outer cavity 2 is formed by sealing the outer wall of the outer cavity heating tube 4 and the inner wall of the outer casing 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com