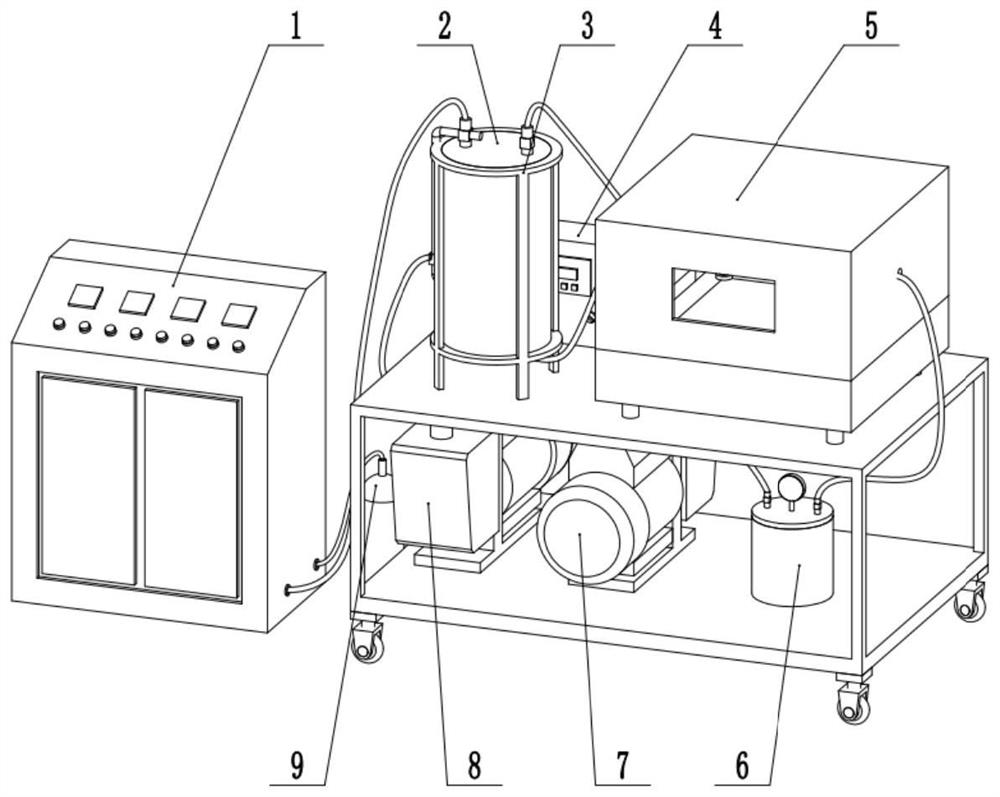

A continuous fiber reinforced thermoplastic resin vacuum bag compression molding device and method

A technology of reinforced thermoplastic and continuous fiber, which is applied in the field of composite material manufacturing, which can solve the problems of poor combination of fiber and resin matrix interface, dehydration and degassing of resin raw materials, and impact on application performance, so as to reduce the volatilization of toxic resin vapor and strengthen Impregnation and bonding effects, effects of overcoming temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

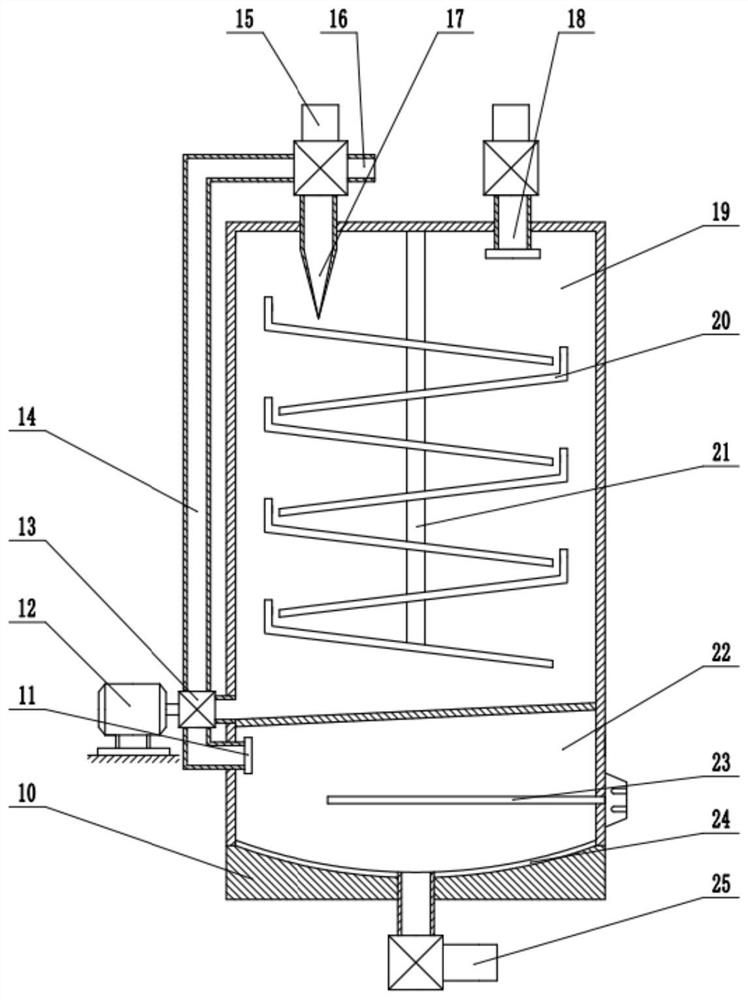

[0072] 50 parts by weight of caprolactam, 2 parts by weight of sodium caprolactam and 0.5 parts by weight of methyl silicone oil, 50 parts by weight of caprolactam, 2 parts by weight of hexamethylene-1,6-diformyl caprolactam and 0.5 parts by weight of methyl silicone oil are added to the resin The two resin tanks of the device 1 are heated to 90°C, kept in a stirring state, mixed evenly, and introduced into the raw material pretreatment device 2 through a conduit, and dehydrated and degassed through the heating flow channel 20 in the vacuum chamber 19, and then passed The diversion hole 11 enters into the material storage chamber 22, where it is heated to 100° C. and maintained.

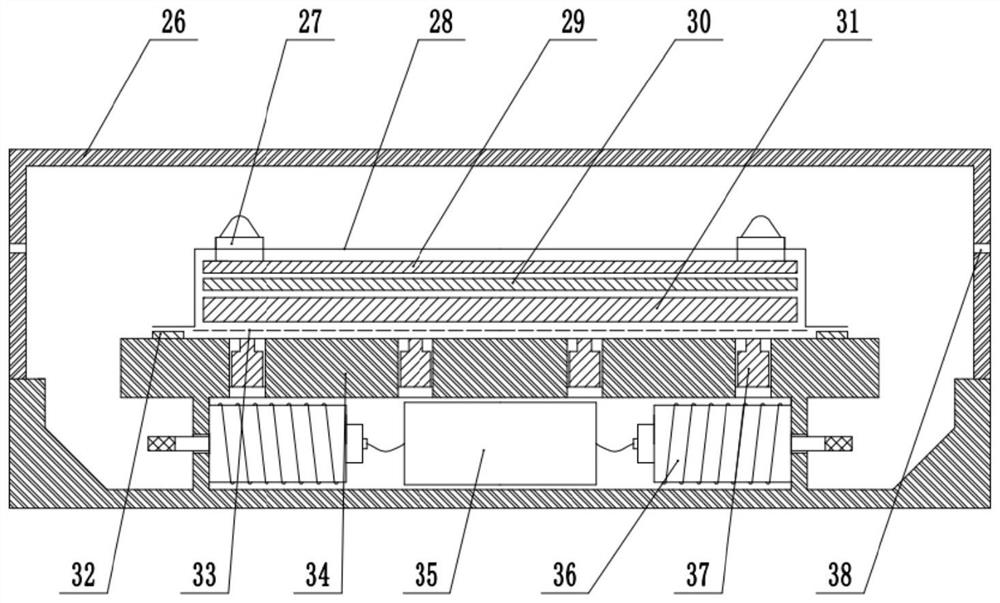

[0073] Cut the glass fiber cloth into a shape of suitable size, apply the release agent 33 on the mold 34, lay the glass fiber cloth 31, the release cloth 30, the diversion net 29, the glue injection seat 27 in sequence, and use the vacuum bag film 28 to place the preformed The immersion body is seal...

specific Embodiment 2

[0077]Put 50 parts by weight of caprolactam, 4 parts by weight of caprolactam magnesium bromide and 1 part by weight of simethicone oil, 50 parts by weight of caprolactam, 4 parts by weight of N-acetylated caprolactam and 1 part by weight of simethicone oil into the resin supply device 1 The two resin tanks are heated to 110°C, kept in a stirring state, mixed evenly, and then introduced into the raw material pretreatment device 2 through a conduit, dehydrated and degassed through the heating flow channel 20 in the vacuum chamber 19, and enter the storage tank through the diversion hole. In the material cavity 11, it is heated to 100°C and maintained therein.

[0078] Cut the glass fiber cloth into a shape of suitable size, apply the release agent 33 on the mold 34, lay the glass fiber cloth 31, the release cloth 30, the diversion net 29, the glue injection seat 27 in sequence, and use the vacuum bag film 28 to place the preformed The immersion body is sealed. The discharge po...

specific Embodiment 3

[0082] 50 parts by weight of caprolactam, 6 parts by weight of sodium ethylate and 1.5 parts by weight of sodium stearate, 50 parts by weight of caprolactam, 6 parts by weight of isophthalyl dicaprolactam and 1.5 parts by weight of sodium stearate are placed in the resin supply device respectively The two resin tanks are heated to 100°C, kept in a stirring state, mixed evenly, and then introduced into the raw material pretreatment device through a catheter, dehydrated and degassed through the heating flow channel in the vacuum chamber, and enter the storage chamber through the diversion hole , in which heated to 100 ° C and maintained.

[0083] Cut the carbon fiber cloth into a shape of suitable size, apply the release agent 33 on the mold 34, lay the carbon fiber cloth 31, the release cloth 30, the guide net 29, and the injection seat 27 in sequence, and use the vacuum bag film 28 to seal the prepreg seal. The discharge port 25 of the raw material pretreatment device 1 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com