Distribution transformer body drying treatment converter power supply device and treatment method

A distribution transformer and drying treatment technology, which is applied in the field of transformer equipment, can solve the problems of damage to the life of insulating materials, insufficient drying degree of low-temperature windings, and inability to realize heating and drying treatment of under-temperature windings, so as to protect the life of insulation and improve the drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

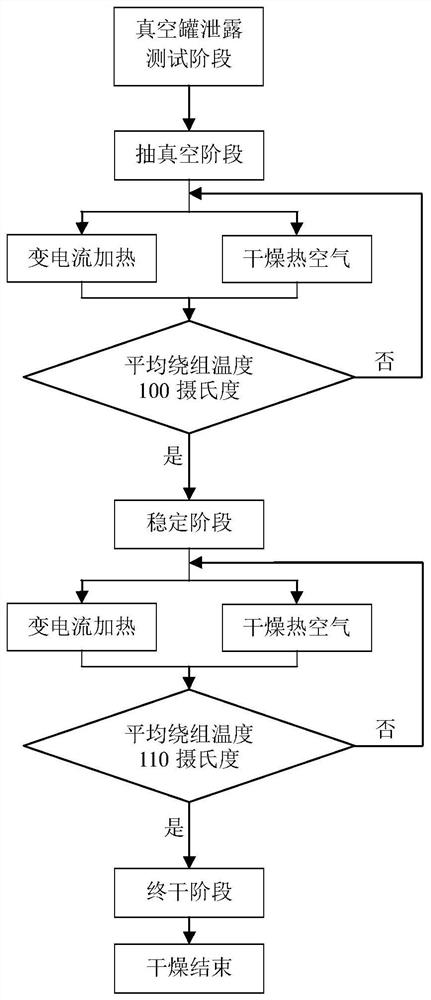

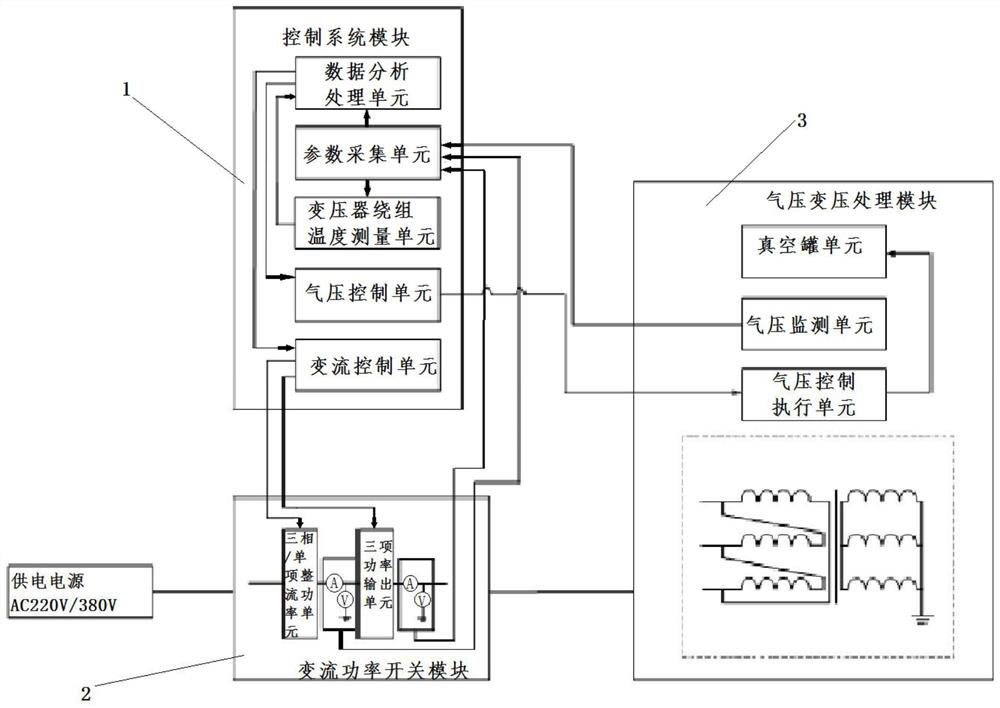

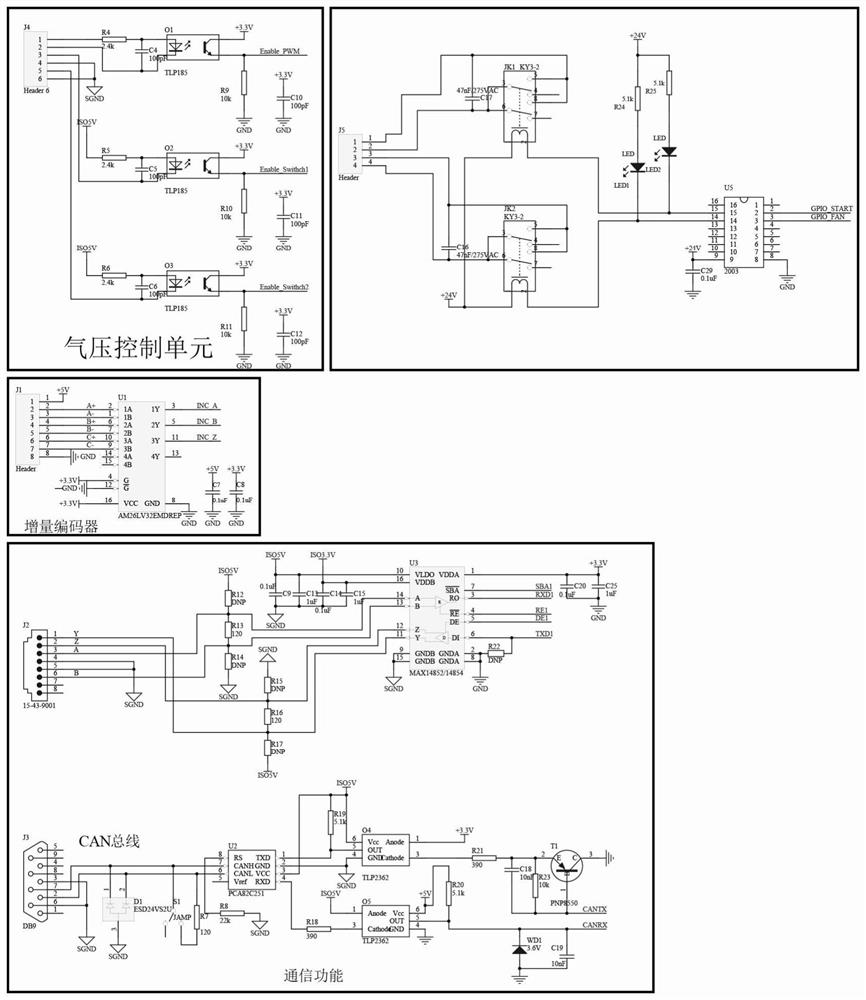

[0080] Such as Figure 1-9 As shown, a transformer drying device includes a control system module, a variable current power switch module, and an air pressure transformation processing module. The control system module collects the parameters of the built-in sensors of the variable current power switch module and the air pressure variable pressure processing module. pressure level. The 220V / 380V power supply is connected to the variable current power switch module. The built-in sensor of the module provides voltage and current electrical quantity signals to the system control module, accepts the control signals issued by the system control module, and outputs different types of current signals for power distribution. The high voltage winding of the transformer body supplies power. The built-in air pressure sensor of the air pressure variable processing module provides air pressure non-electrical signal input to the control system module, and accepts the control signal issued...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com