High-speed line impedance continuity realization method

A realization method and continuous technology, applied in the direction of computer design circuit, electrical components, printed circuit manufacturing, etc., can solve the problems of products not working normally, and signal integrity cannot be determined and eliminated as early as possible, so as to reduce the impedance of high-speed signal lines. Continuous, easy to promote, simple design process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

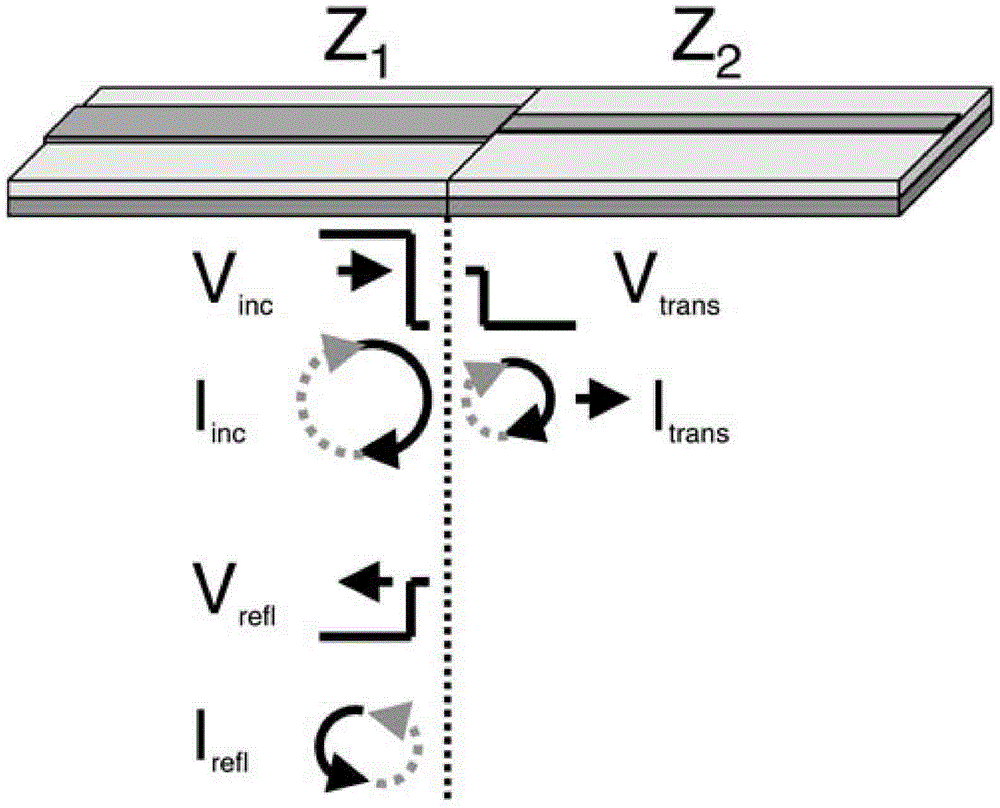

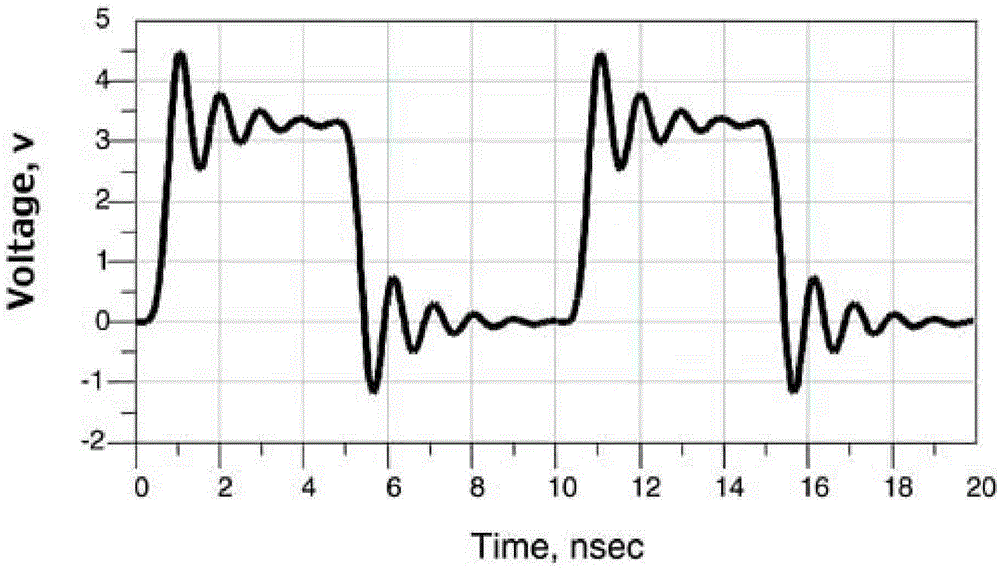

[0019] The present invention proposes a design method for realizing the continuity of high-speed line impedance. The salient features are: in the breakout area inside the BGA (due to the limited space under the BGA and at the pin end, the wiring in this area cannot be routed according to the normal line width and line spacing, and usually requires Make the line width thinner and the spacing smaller to meet the wiring requirements. This wiring area is called the breakout area). Due to the limited space, the wiring has to be thinner and the line spacing smaller, so that the impedance is discontinuous.

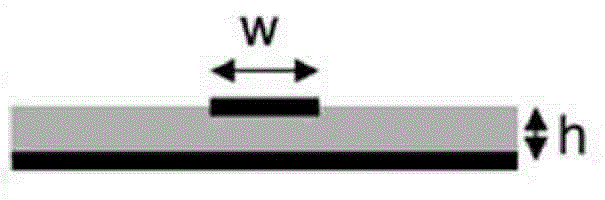

[0020] In order to solve the problem of impedance discontinuity caused by wiring in the breakout area, the present invention uses the surface of the wiring in the breakout area to achieve a standard signal impedance value by increasing or decreasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com