Optical module and communication equipment

A technology of optical modules and signal keys, applied in the field of optical communication, can solve problems such as reduced sensitivity, signal integrity problems, poor eye diagrams, etc., and achieve the effect of reducing impedance discontinuities and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

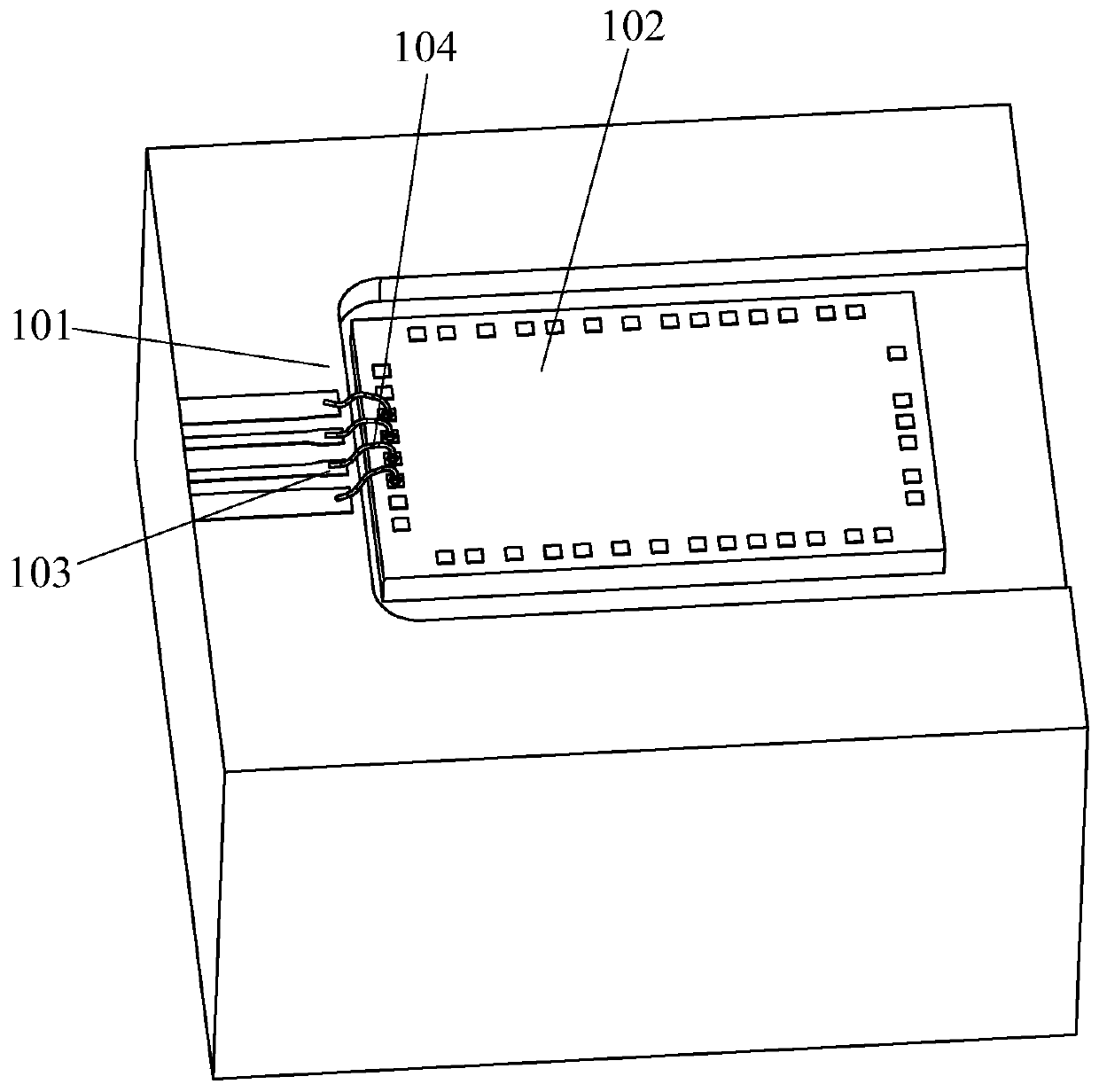

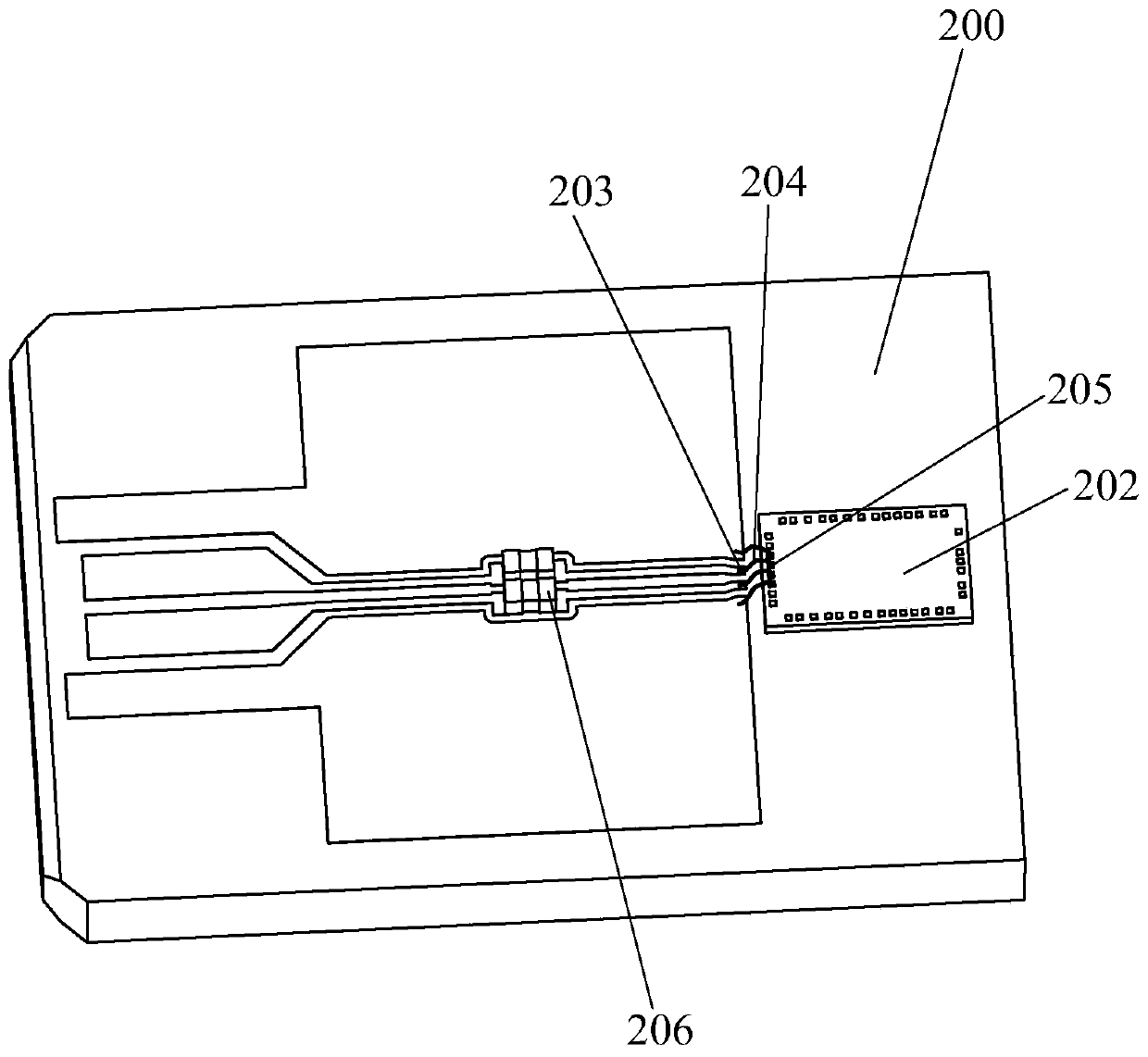

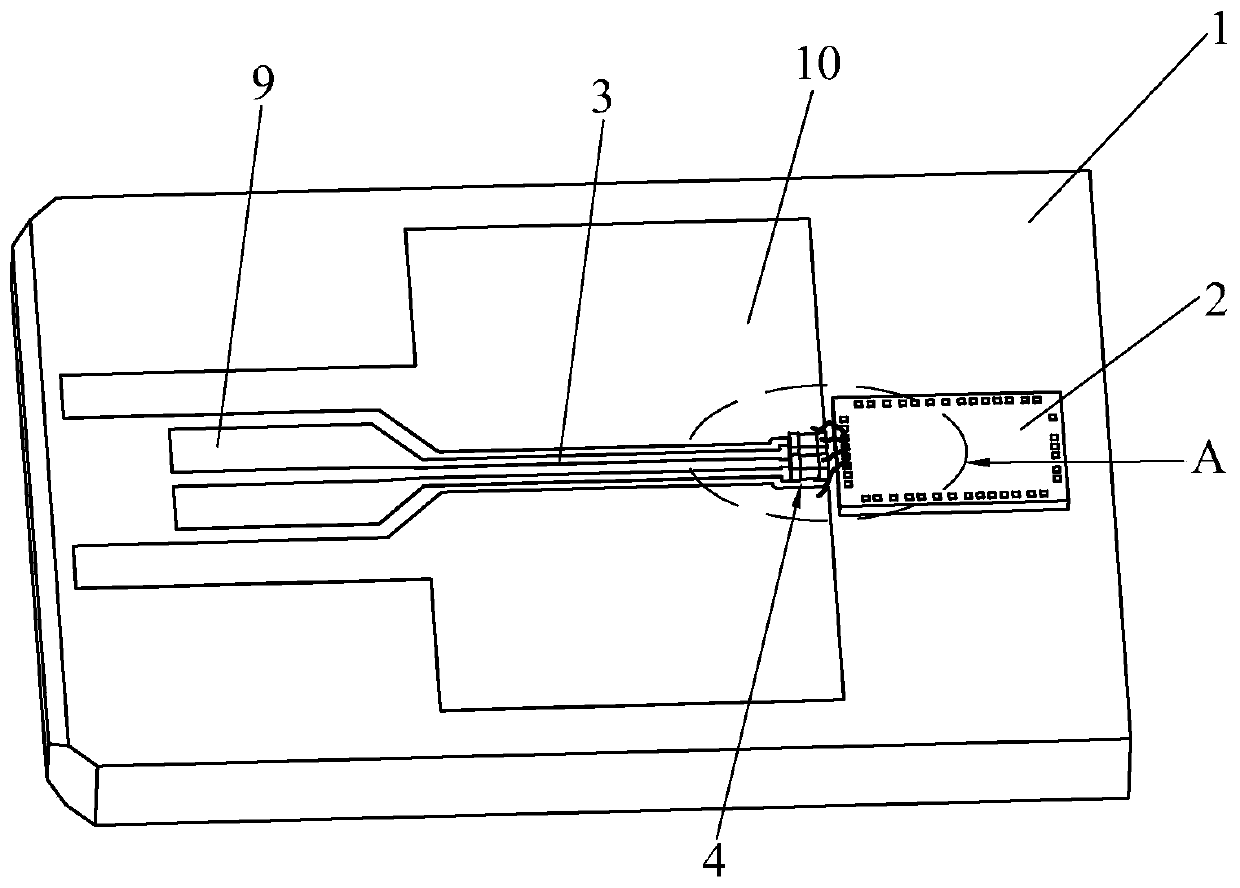

[0022] see Figure 3 to Figure 6 , the invention discloses an optical module, comprising a substrate 1, an electric chip 2, a high-speed signal line 3 and a capacitor 4 / 5, the electric chip 2, a high-speed signal line 3 and a capacitor 4 / 5 are arranged on the substrate 1, and the capacitor 4 / 5 5 is connected between the electric chip 2 and the high-speed signal line 3, the capacitor 4 / 5 includes the first pole plate 41 / 51 and the second pole plate 42 / 52, the first pole plate 41 / 51 is connected to the electric The corresponding pad 21 of the chip 2 is connected, and the second plate 42 / 52 is connected to the high-speed signal line 3 . Generally speaking, the signal bonding wire 6 is bonded on the upper surface of the first plate 41 / 51 , but not limited theret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com