Method for releasing the pressure in a fuel system in a crash

A fuel system and fuel tank technology, which is applied in the layout, power plant, electric power plant, etc. combined with the fuel supply of internal combustion engines, can solve problems such as explosion, and achieve the effects of reducing cost, eliminating demand, and improving configurability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

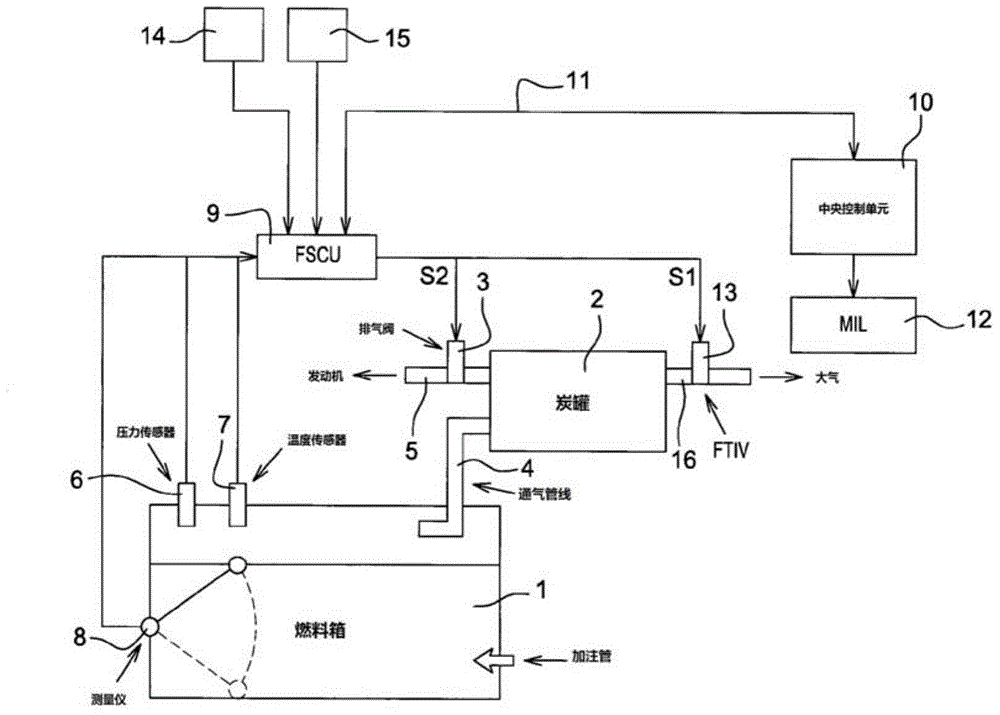

[0039] figure 1 A fuel system according to a particular embodiment of the invention is shown. The fuel system is installed on the vehicle. The fuel system includes a fuel tank 1 , and the fuel tank 1 communicates with a carbon canister 2 through a vent line 4 . The canister 2 has another breather line 5 connected to the intake manifold (not shown) of the internal combustion engine. An exhaust valve 3 is provided in the breather line 5 to enable selective communication between the canister 2 and an intake manifold (not shown). There is also an additional communication channel between the carbon canister 2 and the atmosphere. This communication can be selectively controlled by a fuel tank isolation valve, FTIV 13, to create a fully sealed fuel system.

[0040] exist figure 1 In the example shown, the FTIV 13 is arranged in the ventilation line 16 . When the FTIV 13 is opened, it enables the canister 2 to communicate with the atmosphere, and enables the fuel vapor in the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com