Polyamide-poly(phenylene ether) fiber, article, composition, and method

A technology of polyamide and composition, applied in polyamide-polyphenylene ether fibers, products, compositions and fields, capable of solving problems such as poor particle dispersion of spinning fine fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

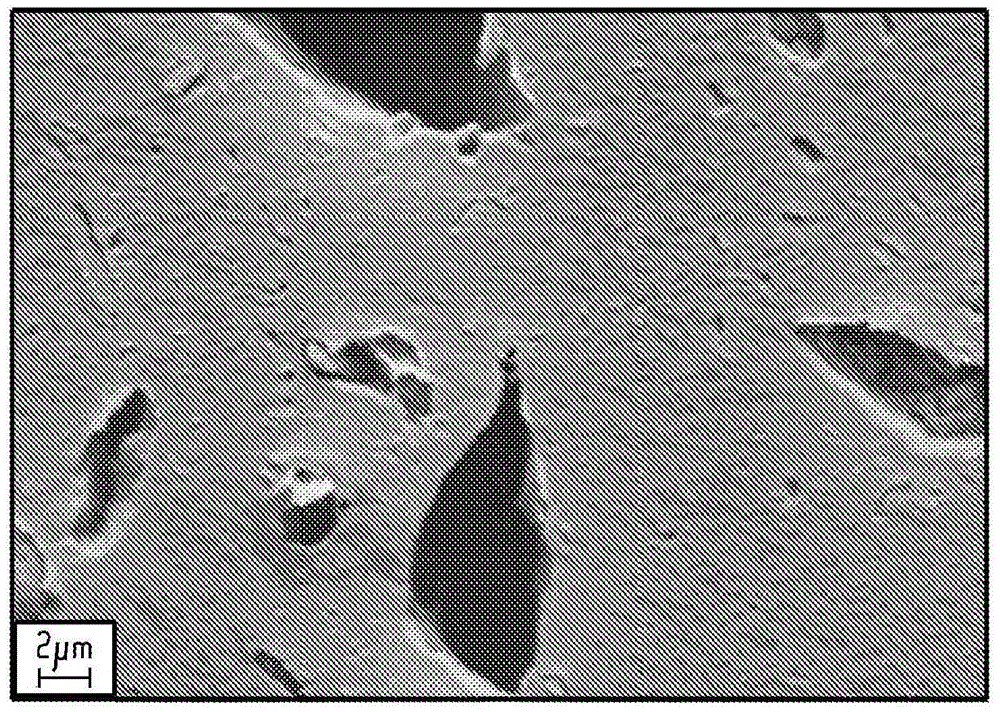

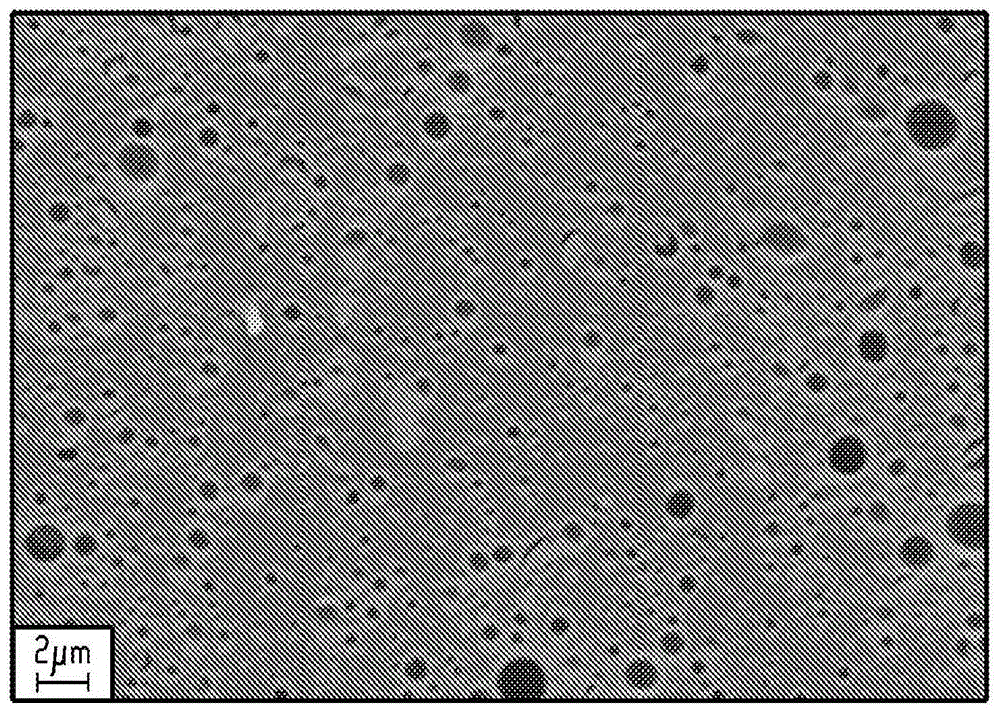

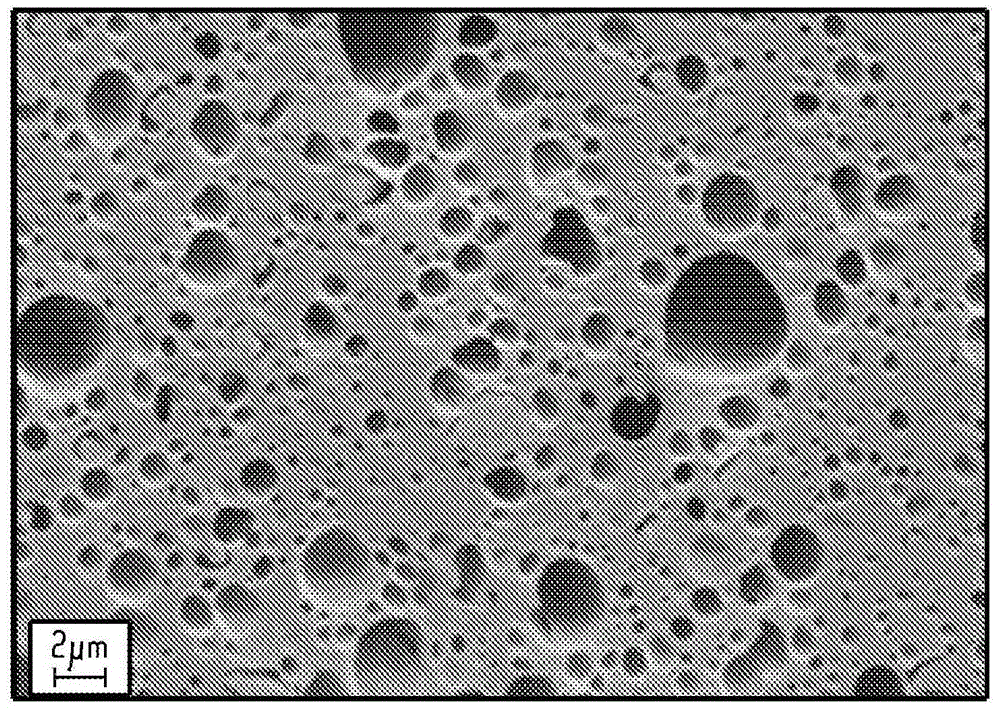

[0120] Embodiment 1: A fiber comprising a composition comprising melt blending: 58 to 93.9 weight percent of a polyamide selected from the group consisting of polyamide-6, polyamide-6,6, and combinations thereof; 5 to 35 weight percent polyphenylene ether-polysiloxane block copolymer reaction product comprising polyphenylene ether and polyphenylene ether-polysiloxane block copolymer; 1 to 10 weight percent Flame retardant of phosphonate; and 0.1 to 2 weight percent of compatibilizer for polyamide and polyphenylene ether-polysiloxane block copolymer reaction product; wherein, all weight percentages are based on the total composition weight; and wherein the composition comprises a continuous phase comprising polyamide and a dispersed phase comprising a polyphenylene ether-polysiloxane block copolymer reaction product; wherein, based on the number of dispersed phase particles, the dispersed phase particles have Less than or equal to 0.9 μm measured by microscope 2 average cross-...

Embodiment approach 2

[0121] Embodiment 2: The fiber of Embodiment 1, wherein the melt blending comprises melt blending a polyphenylene ether-polysiloxane block copolymer reaction product, a flame retardant, and a compatibilizer with a polyamide-based 15 to 70 weight percent polyamide to form an intermediate composition, and melt blending the intermediate composition with the remaining polyamide to form a composition.

Embodiment approach 3

[0122] Embodiment 3: The fiber according to Embodiment 1 or 2, wherein the polyamide is polyamide-6,6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com