Coater for diaphragm coating

A technology of coating machine and diaphragm, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc. It can solve the problems of affecting coating speed, low solid content, and coating system can not be applied, etc., to achieve guaranteed The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

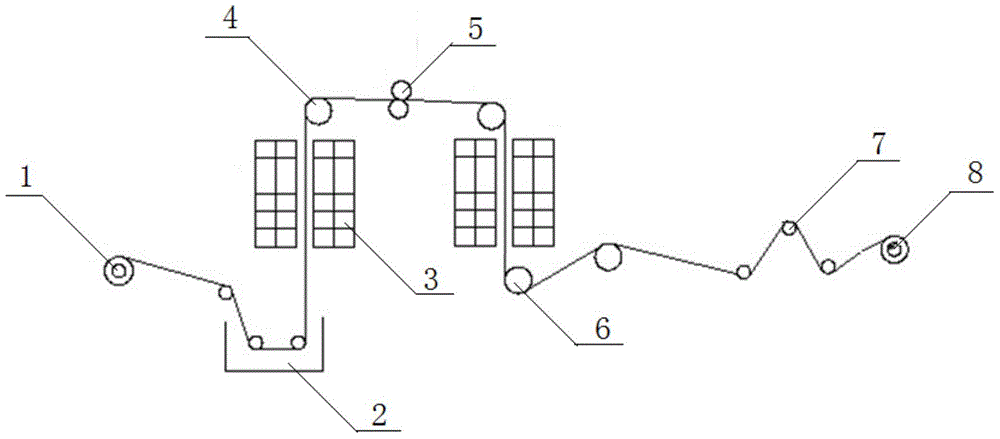

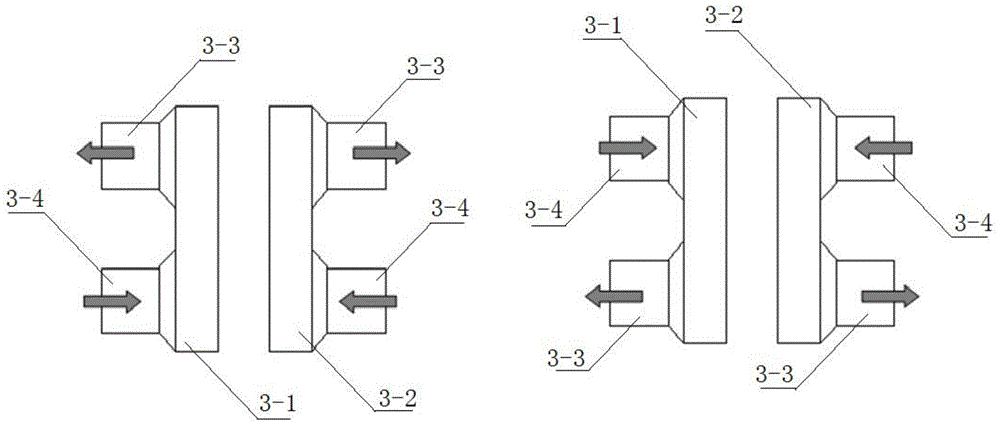

[0024] A coating machine for coating diaphragm, including unwinding roller 1, gluing device 2, two vertical oven groups 3, traction roller 4, kneading part 5, guide roller 6, flattening roller 7, winding Roller 8 and main body traction motor, described gluing device 2 is made up of feed liquid groove and coating roller, and described coating roller is arranged above described feed liquid groove, and described each vertical oven group 3 is made up of symmetrically arranged The first vertical oven 3-1 and the second vertical oven 3-2 are composed, and the height of the first vertical oven 3-1 and the second vertical oven 3-2 of the vertical oven group 3 is 2 meters , and with an independent heating and blowing device, the vertical oven group 3 is provided with air nozzles, wherein the upper air nozzles of a group of vertical oven groups 3 are air outlets 3-3, and the lower air nozzles are air inlets. The tuyere 3-4, the upper tuyere of the other vertical oven group 3 is the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com