Reed suspension structure for standard vibrating table

A vibrating table and reed technology, which is applied to fluids, measuring devices, and instruments that utilize vibration, can solve the problems of high machining accuracy requirements for parts, large distortion of the vibrating table, and poor linear characteristics, and reduce manufacturing costs. Cost, improved accuracy, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

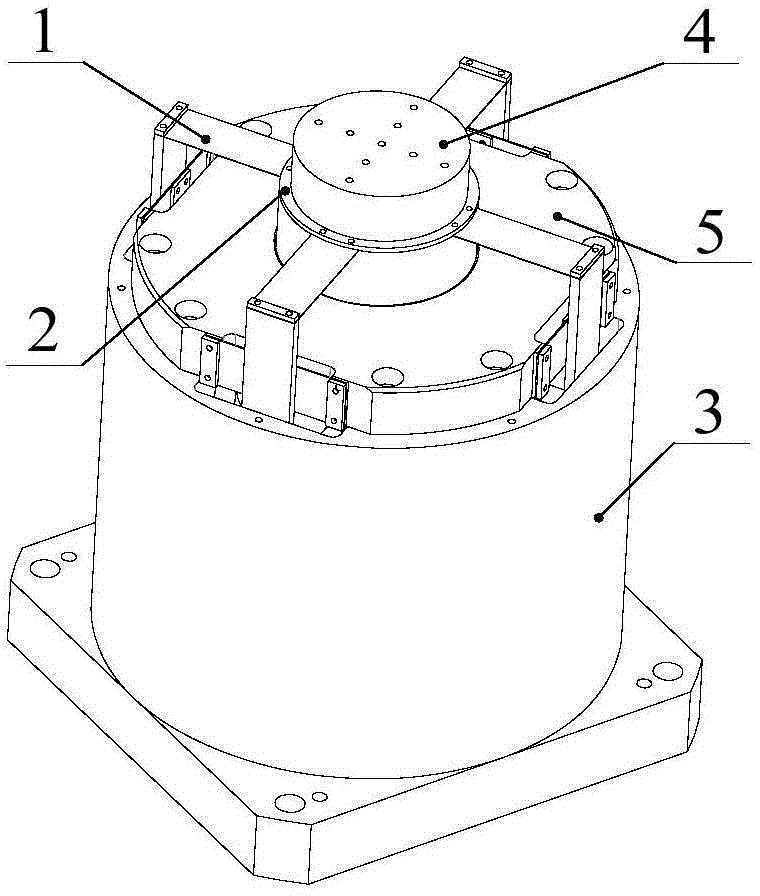

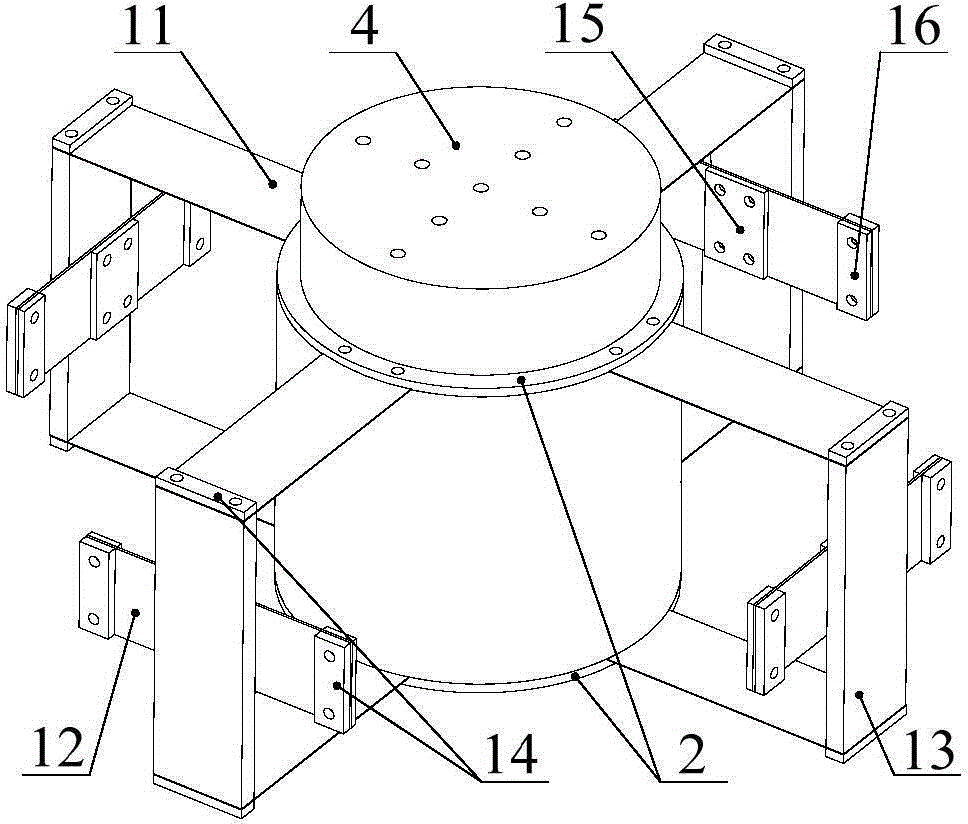

[0022] Such as figure 1 As shown, the reed suspension structure for a standard vibrating table includes four sets of reed suspension units 1 and a connecting ring 2 connecting the reed suspension unit 1 and the moving part 4 of the vibrating table 3, and the connecting ring 2 is fixed on the vibrating On the moving part 4 of the table 3, the connecting ring 2 is coaxial with the moving part 4 of the vibrating table 3;

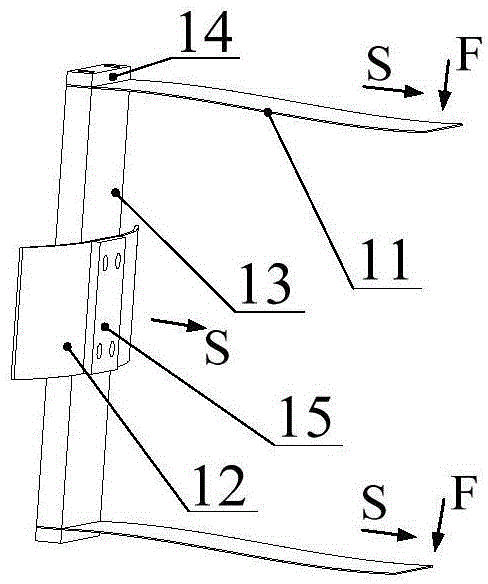

[0023] to combine figure 2 , each reed suspension unit 1 includes a pair of horizontal reeds 11, a reed support block 13 and a side reed 12; a pair of horizontal reeds 11 are respectively fixed to the two ends of the reed support block 13, The other end of the horizontal reed 11 is fixed on the connecting ring 2, and the reed support block 13 is arranged axially along the moving part 4 of the vibrating table 3; the side reed 12 is fixed on the reed support block 13, and the side reed 12 and the spring The sheet support block 13 is orthogonal, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com