Cutting and chamfering control device and pipe cutting machine

A technology of control device and pipe cutting machine, which is applied in shearing device, feeding device, positioning device, etc., can solve the problem that the chamfering accuracy needs to be improved, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

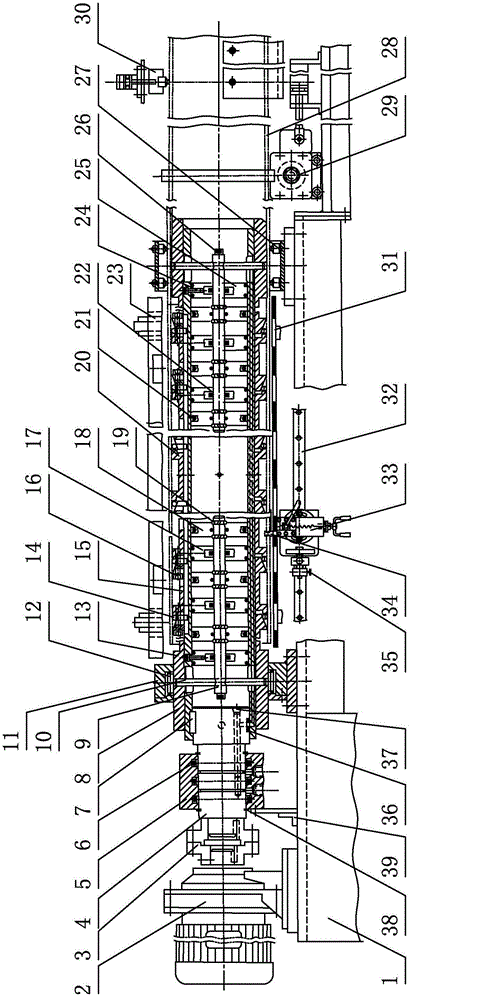

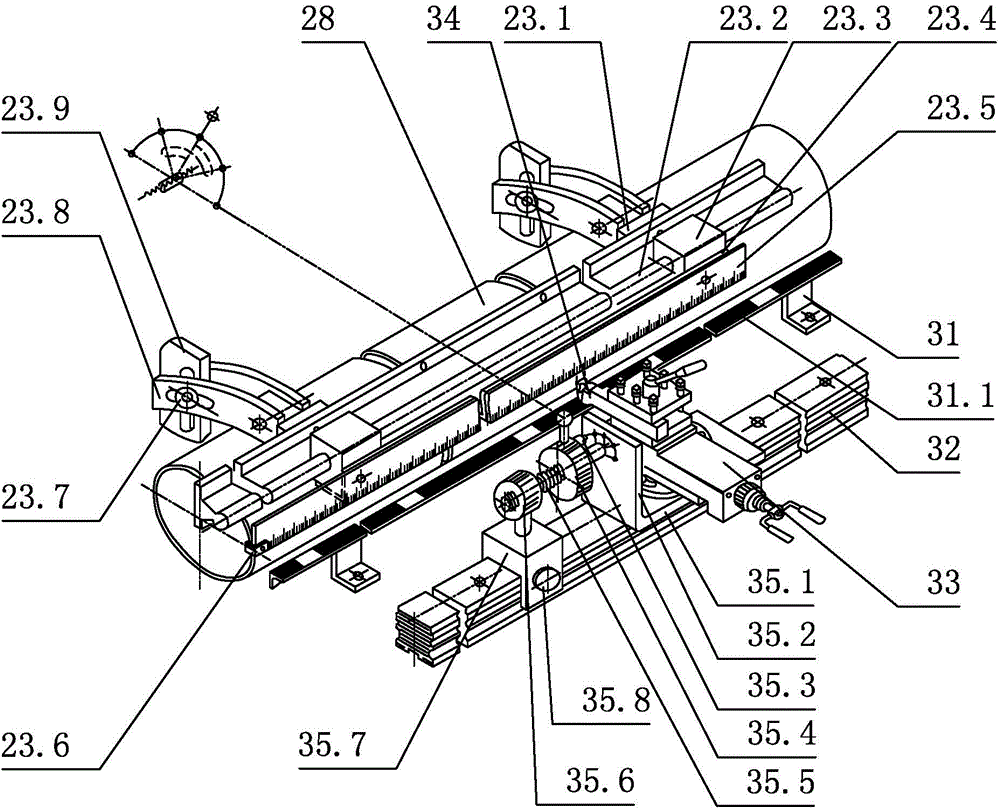

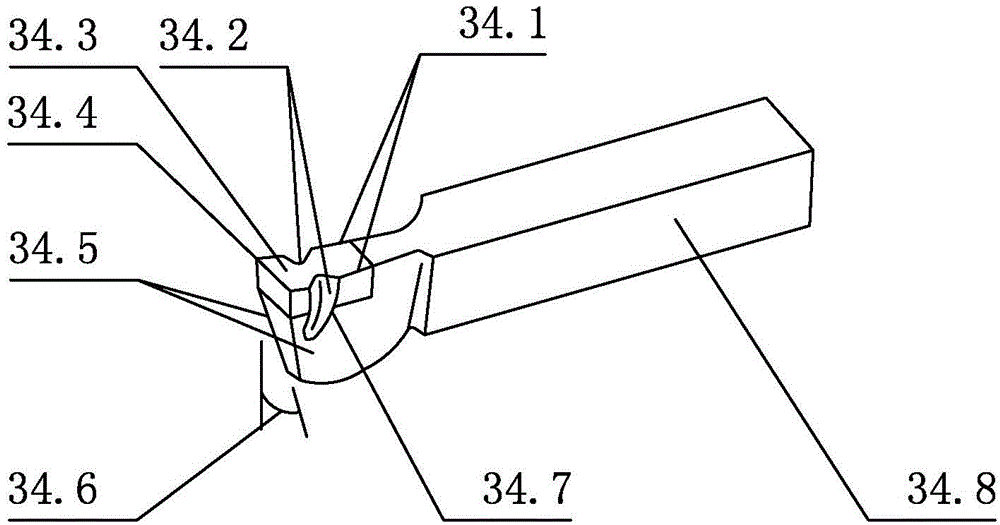

[0076] Such as figure 1As shown, the pipe cutting machine includes a machine base 1, a motor reducer 2 fixedly installed on the machine base 1, and a frequency conversion speed regulating motor can also be directly used, and the number of revolutions of the motor reducer is between 50 and 1000 rpm. The motor reducer 2 is connected to the mandrel 4 through the coupling 3, the right side of the mandrel 4 is connected to the main shaft tube 8 through the key 7 and fixed, the left end of the main shaft tube 8 is provided with a shaft support seat 11, and the outer periphery of the main shaft tube 8 is provided with a material tube for fastening device, the material tube 28 is set on the material tube fastening device, the right end of the main shaft tube 8 is provided with a shaft end bearing assembly 27 supporting the material tube 28, and the rear side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com