A processing method for a semicircular thin-walled collar matched with a shaft

A processing method and collar technology are applied in the processing field of semicircular thin-walled collars, which can solve the problems of unqualified processing dimensions of semicircular thin-walled collars, distortion of workpieces, low product qualification rate, etc. Stress, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

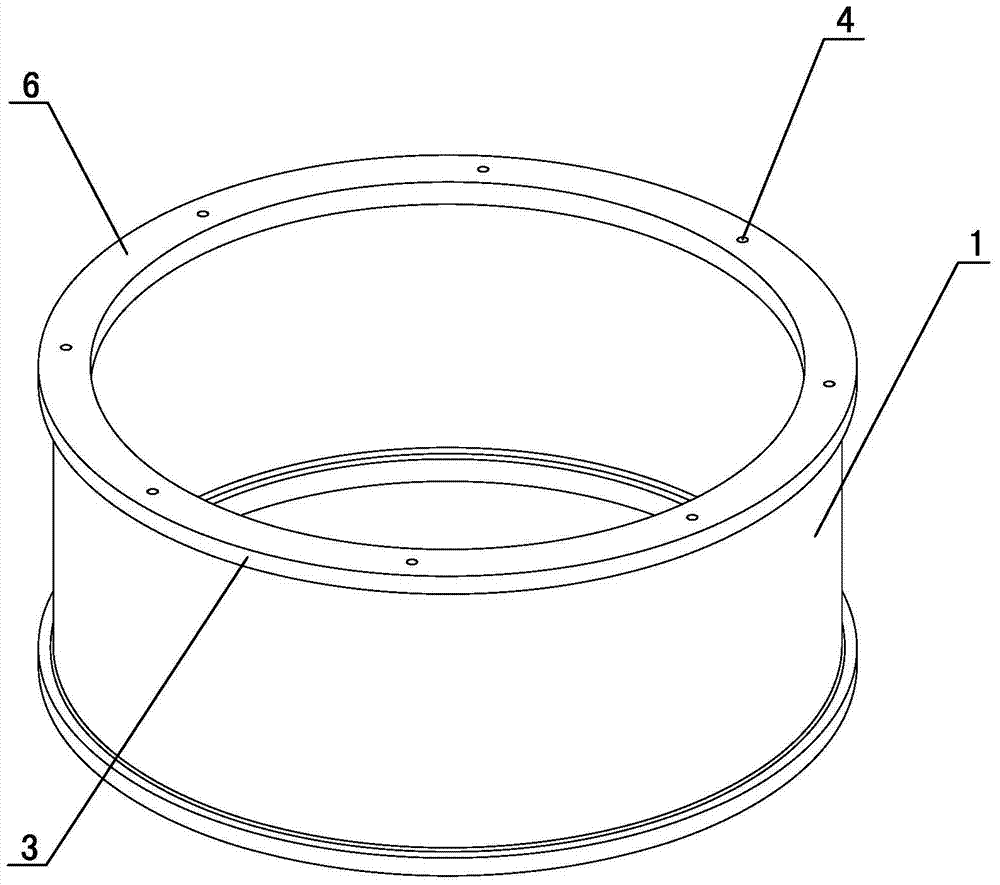

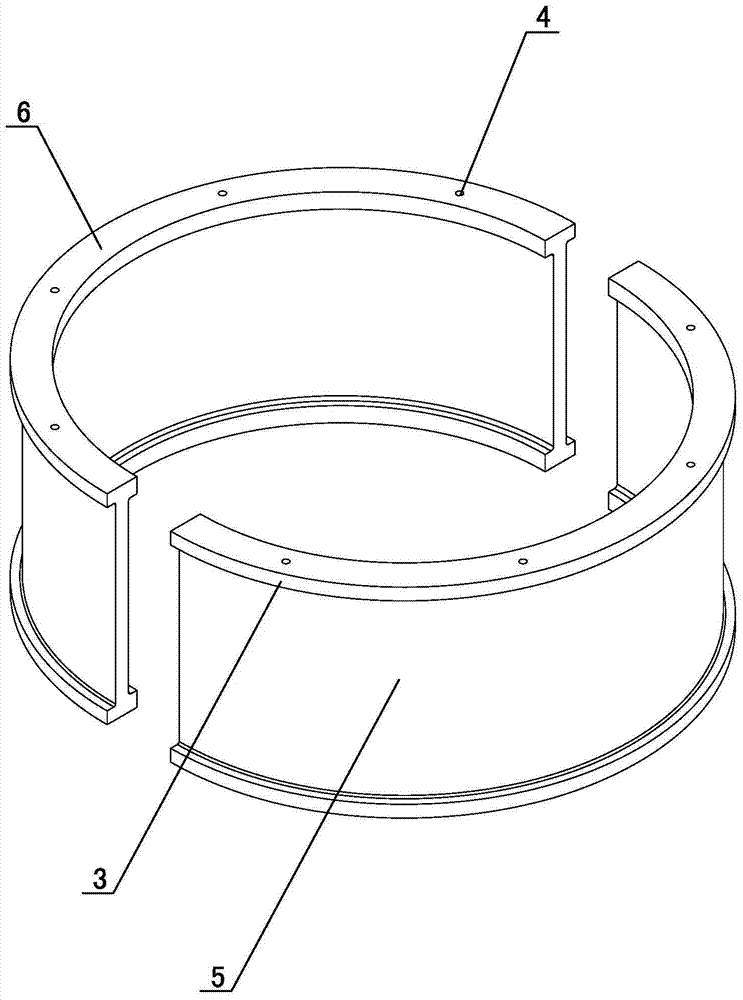

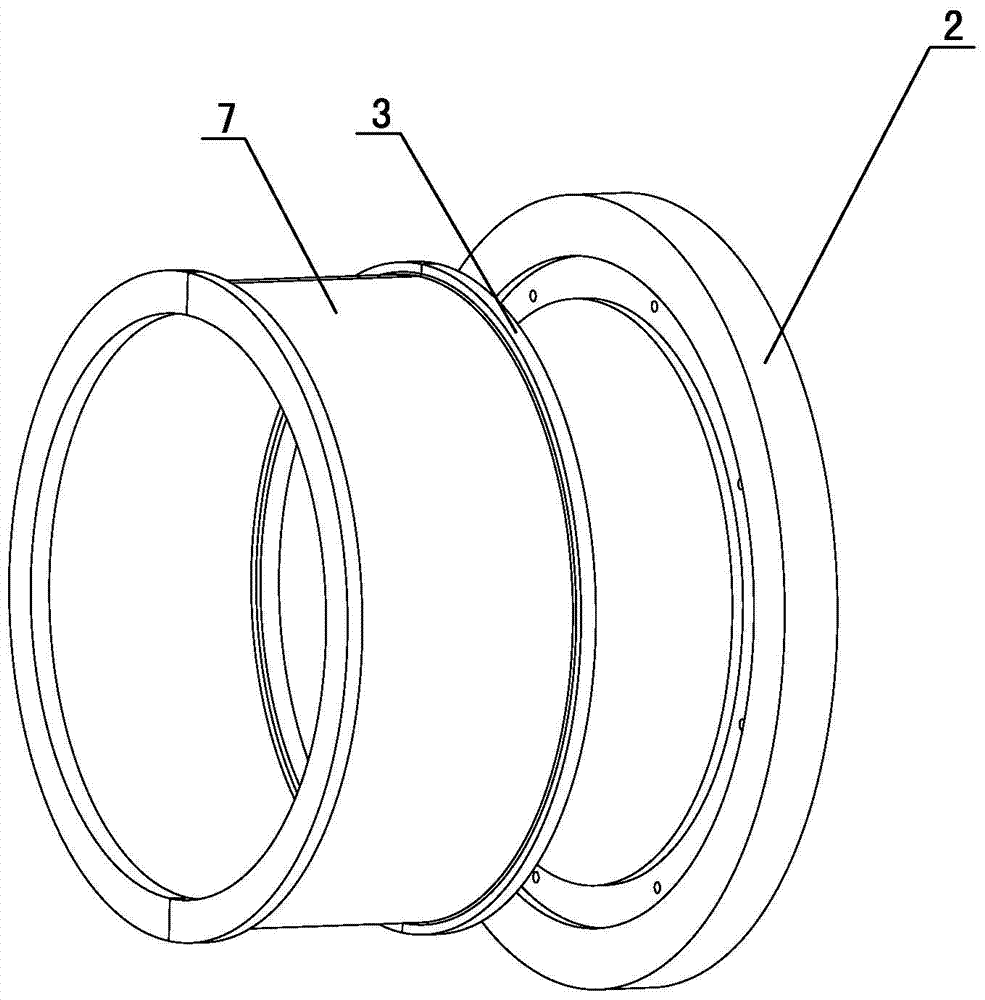

[0019] Embodiment 1: As shown in the figure, a processing method for a semicircular thin-walled collar that cooperates with a shaft includes the following specific steps:

[0020] ①Take the ring-shaped workpiece 1 to be processed, rough the inner diameter or outer diameter of the ring-shaped workpiece 1, reserve a diameter margin of 1mm, and process the fixed threaded hole on the installation step 3 where the ring-shaped workpiece 1 and the jig 2 cooperate 4. The number and position of the fixed threaded holes 4 correspond to the threaded holes on the jig 2 one by one;

[0021] ② Anneal the ring-shaped workpiece 1 after rough turning at a temperature of 200°C, then heat the ring-shaped workpiece 1 at 200°C for 5 hours, and cool it naturally; anneal the ring-shaped workpiece 1 after rough turning Treatment to eliminate the stress of the ring-shaped workpiece 1 and prevent the workpiece from twisting and deforming;

[0022] ③Semi-finishing the inner diameter or outer diameter o...

Embodiment 2

[0029] Embodiment 2: As shown in the figure, a method for processing a semicircular thin-walled collar that cooperates with a shaft includes the following specific steps:

[0030] ①Take the ring-shaped workpiece 1 to be processed, rough the inner diameter or outer diameter of the ring-shaped workpiece 1, reserve a diameter margin of 1.5mm, and process the fixed thread on the installation step 3 where the ring-shaped workpiece 1 and the jig 2 cooperate Holes 4, the number and position of the fixed threaded holes 4 are in one-to-one correspondence with the threaded holes on the jig 2;

[0031] ② Anneal the ring-shaped workpiece 1 after rough turning at a temperature of 200°C, then heat the ring-shaped workpiece 1 at 200°C for 5 hours, and cool it naturally; anneal the ring-shaped workpiece 1 after rough turning Treatment to eliminate the stress of the ring-shaped workpiece 1 and prevent the workpiece from twisting and deforming;

[0032] ③Reserve a margin of 0.75mm for the inne...

Embodiment 3

[0039] Embodiment 3: As shown in the figure, a processing method for a semicircular thin-walled collar that cooperates with a shaft includes the following specific steps:

[0040] ①Take the ring-shaped workpiece 1 to be processed, rough the inner diameter or outer diameter of the ring-shaped workpiece 1, reserve a diameter margin of 2mm, and process the fixed threaded hole on the installation step 3 where the ring-shaped workpiece 1 and the jig 2 cooperate 4. The number and position of the fixed threaded holes 4 correspond to the threaded holes on the jig 2 one by one;

[0041] ② Anneal the ring-shaped workpiece 1 after rough turning at a temperature of 200°C, then heat the ring-shaped workpiece 1 at 200°C for 5 hours, and cool it naturally; anneal the ring-shaped workpiece 1 after rough turning Treatment to eliminate the stress of the ring-shaped workpiece 1 and prevent the workpiece from twisting and deforming;

[0042] ③Semi-finishing the inner or outer diameter of the rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com