Quenching oil pool chain motion state monitoring device and monitoring method

A technology of motion state and quenching oil pool, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve problems that cannot meet the production process and condition requirements, and achieve the effect of avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

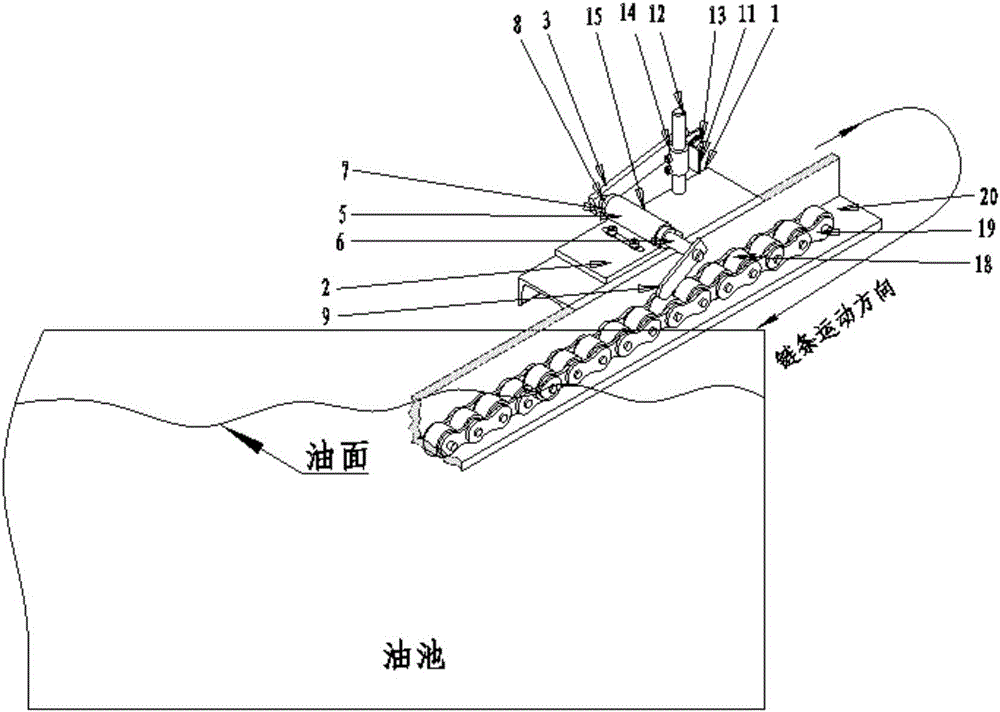

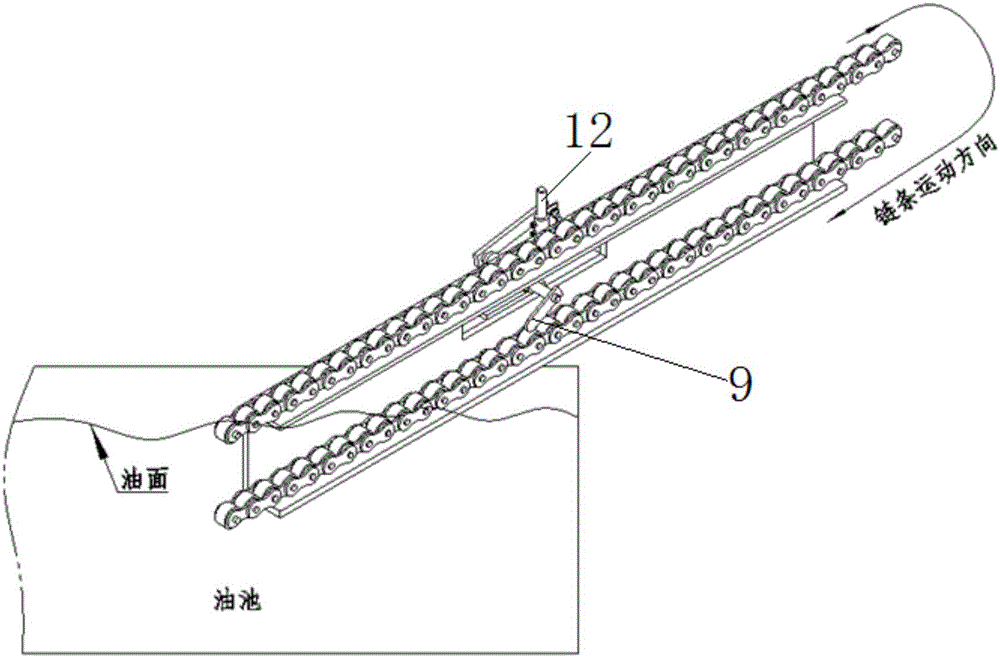

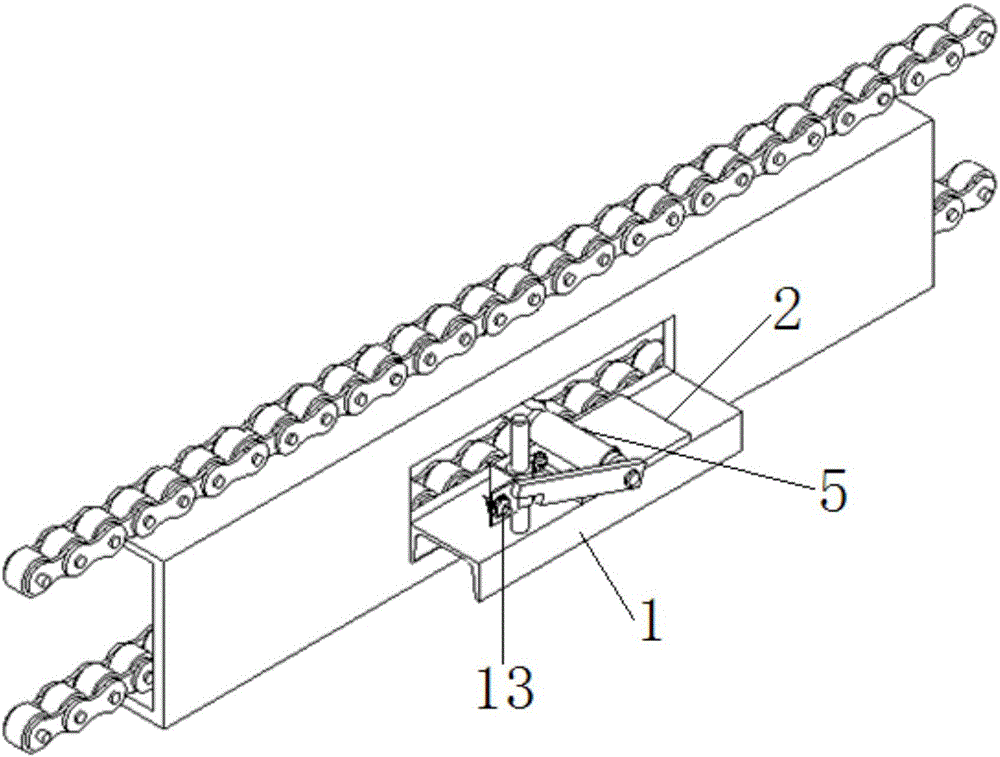

[0017] A quenching oil pool chain motion state monitoring device, such as figure 1 As shown, it includes: detection main bracket 1, adjustment plate 2, detection plate 3, rotation sleeve 5, rotation shaft 6, bearing 7, positioning pad 8, chain contact plate 9, detection frame 11, support rod 12, proximity switch 13. Sleeve 14, screw 15, roller 18, chain 19, dinosaur frame 20, etc. in:

[0018] The main bracket 1 and the side of the dinosaur frame 20 are fixed by welding. An adjustment plate 2 is arranged on the main bracket 1. Two long slots are opened on the adjustment plate 2, and four M8 screws pass through the long slots. The adjusting plate 2 is fixed on the main bracket 1; a positioning groove is arranged on the adjusting plate 2, and the rotating shaft sleeve 5 is welded and fixed on the adjusting plate through the positioning groove; the rotating shaft 6 is arranged in the rotating shaft sleeve 5, and the rotating shaft Needle roller bearings 7 are arranged between 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com