Production Process of Tin Bronze Tempered Bead Wire Highly Bonded to Rubber

A tempering bead and tin bronze technology, which is applied in metal material coating technology, manufacturing tools, liquid chemical plating, etc., can solve the problem of shortening the service life of tires, affecting tire performance, and the adhesion between bead steel wire matrix and rubber Insufficient and other problems, to achieve the effect of increasing the adhesive rate and enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

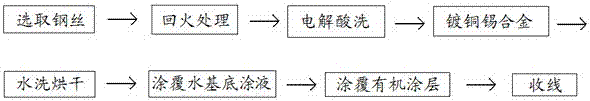

[0011] Embodiment one: a kind of production technology of the tin bronze tempered bead steel wire that is bonded highly with rubber, comprises the following steps: 1., select the steel wire that diameter range is in 0.95mm; 2., pass the steel wire in step 1. through molten lead , tin, bismuth, lead alloy, tin alloy, bismuth alloy solution in any single solution or the mixed solution that is made up of two or more single solutions in them is tempered; 3., step 2. obtained The steel wire is rinsed with water, then electrolytic pickling to form concave-convex points on its surface, and then washed with water; ④, the surface of the steel wire covered with concave-convex points obtained in step ③ by chemical replacement method is coated with copper-tin alloy coating; ⑤ 1. The coated steel wire obtained in step 4. is washed and dried; 6. The surface of the coated steel wire obtained in step 5. is coated with a water base coating solution, and the cold air is dried, and the water base...

Embodiment 2

[0012] Embodiment two: a kind of production technology of the tin bronze tempered bead steel wire that is bonded highly with rubber, comprises the following steps: 1., select the steel wire that diameter range is in 1.20mm; 2. pass the steel wire in step 1. through molten lead , tin, bismuth, lead alloy, tin alloy, bismuth alloy solution in any single solution or the mixed solution that is made up of two or more single solutions in them is tempered; 3., step 2. obtained The steel wire is rinsed with water, then electrolytic pickling to form concave-convex points on its surface, and then washed with water; ④, the surface of the steel wire covered with concave-convex points obtained in step ③ by chemical replacement method is coated with copper-tin alloy coating; ⑤ 1. The coated steel wire obtained in step 4. is washed and dried; 6. The surface of the coated steel wire obtained in step 5. is coated with water base coating liquid, and the cold air is dried, and the water base coat...

Embodiment 3

[0013] Embodiment three: see figure 1 As shown, a production process of tin bronze tempered bead steel wire highly bonded to rubber comprises the following steps: ①, select high-strength steel wire with a diameter range of 1.30mm, ②, pass the steel wire in step ① through the molten Any single solution in lead, tin, bismuth, lead alloy, tin alloy, bismuth alloy solution or a mixed solution composed of two or more single solutions in them is tempered, ③, the obtained in step ② The steel wire is rinsed with water, then electrolytic pickling to form concave and convex points on its surface, and then washed with water, ④, using the chemical replacement method in step ③ The surface of the steel wire covered with concave and convex points is coated with a copper-tin alloy coating, Tin bronze coating weight is 0.39-0.58g / kg, tin content is 4-10%; 5., the coated steel wire obtained in step 4. is carried out cold water washing, removes the residual impurity ion in last step process on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com