Inner supporting device for reinforcement cage of extra-high pressure cast-in-place pile foundation

A technology of internal support and cast-in-place piles, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problem of non-reusable support rods, and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

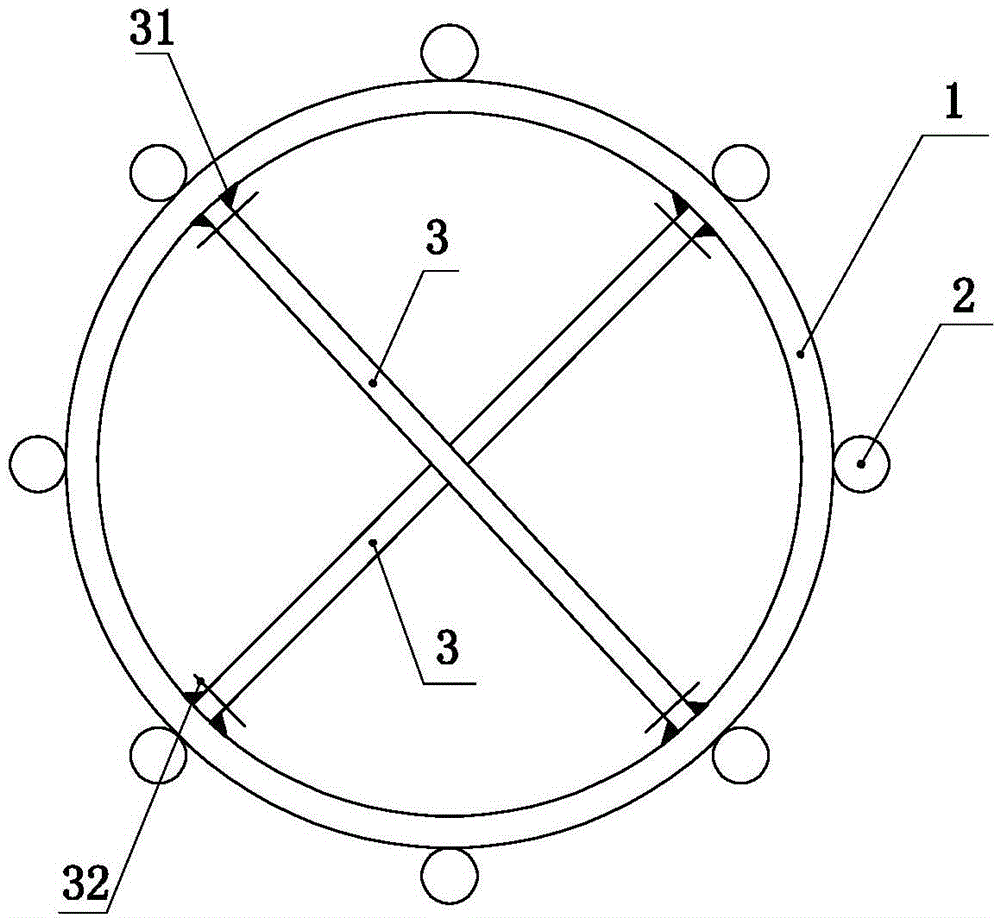

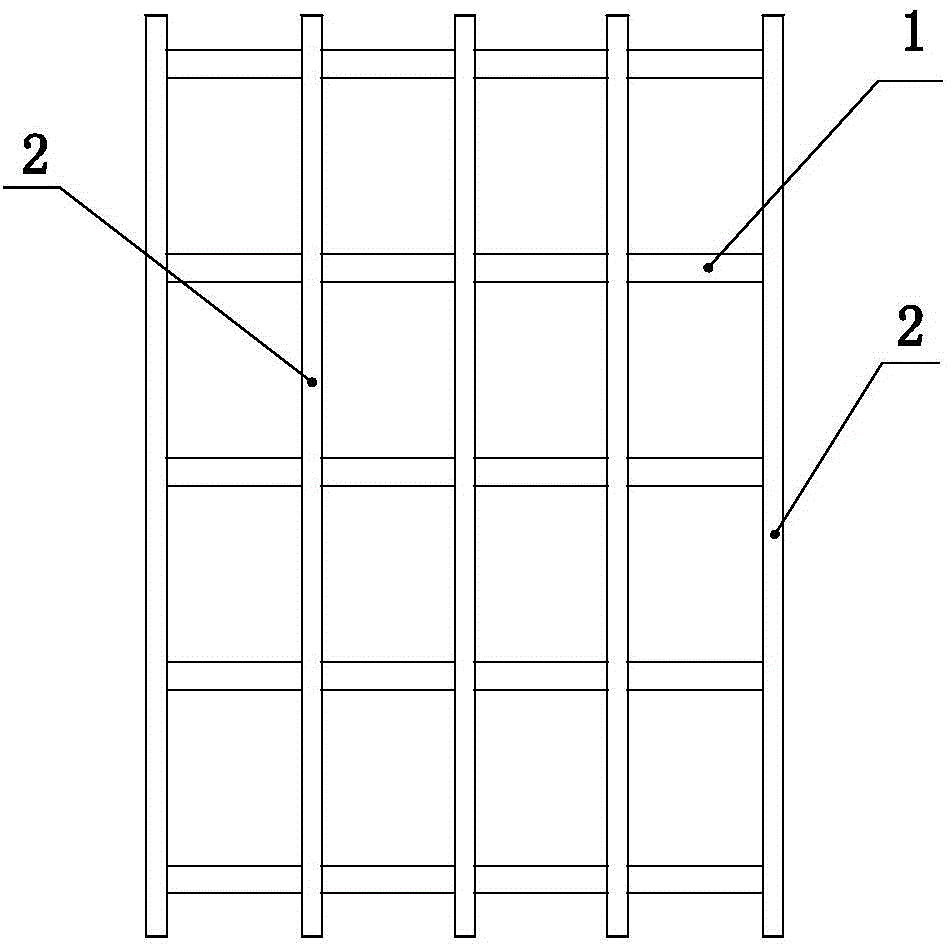

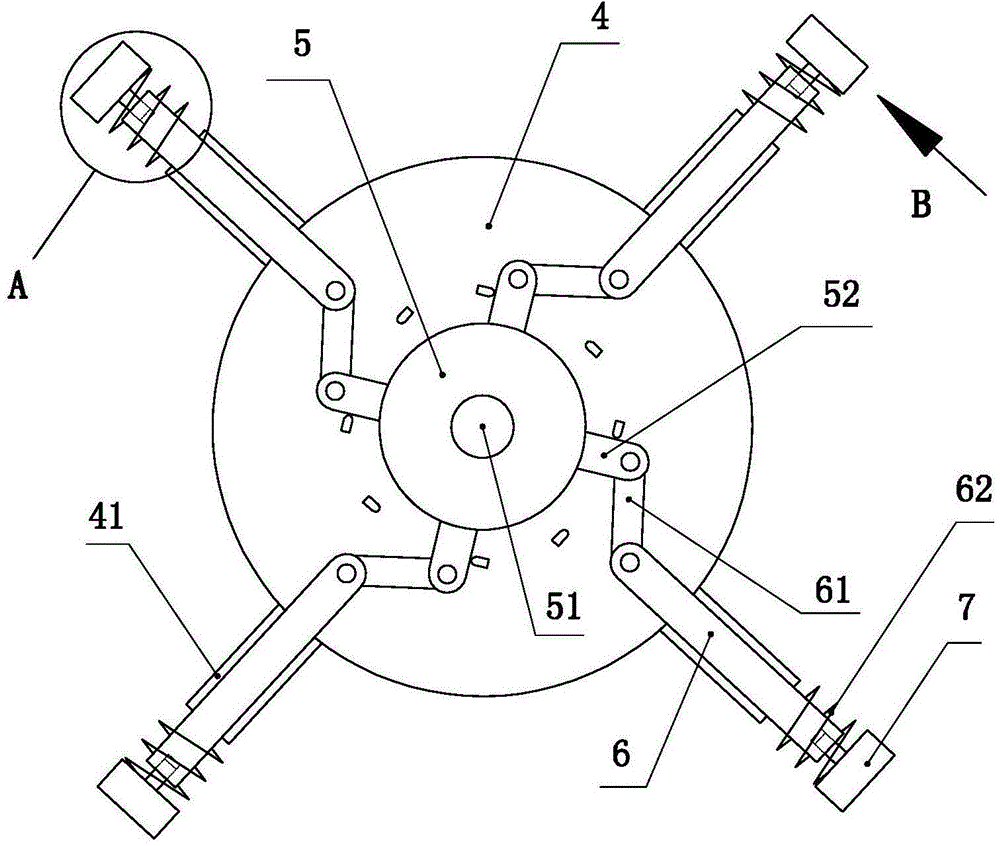

[0026] like Figure 3 to Figure 13 As shown, the present invention comprises fixed disk 4, guide rail 41, rotating disk 5, rotating shaft 51, crank 52, slide rod 6, connecting rod 61, spring 62, pallet 7, guide column 71, worm wheel 8, worm screw 81, driven gear , 82 driving gear 83, motor 84, support 9 and bearing 11, the present invention is described below in conjunction with accompanying drawing.

[0027] like Figure 10 As shown, the fixed disk 4 is a circular metal piece, and the center of the fixed disk is provided with a circular hole 42, such as Figure 12 As shown, a bearing 11 is fixed in the circular hole 42, and a rotating shaft 51 is fixed in the inner ring of the bearing. like image 3 As shown, a rotating disk 5 is arranged on the front side of the fixed disk. The rotating disk is a circular metal piece. The rotating disk is fixed on the rotating shaft. Four cranks 52 are arranged on the outer wall of the rotating disk. On the turntable, the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com