Motorcycle engine piston cooling mechanism

A piston cooling and engine technology, which is applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems that the piston cannot be cooled and occupies a large space, so as to overcome the thermal deformation of the piston and expand the cylinder, saving space , the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

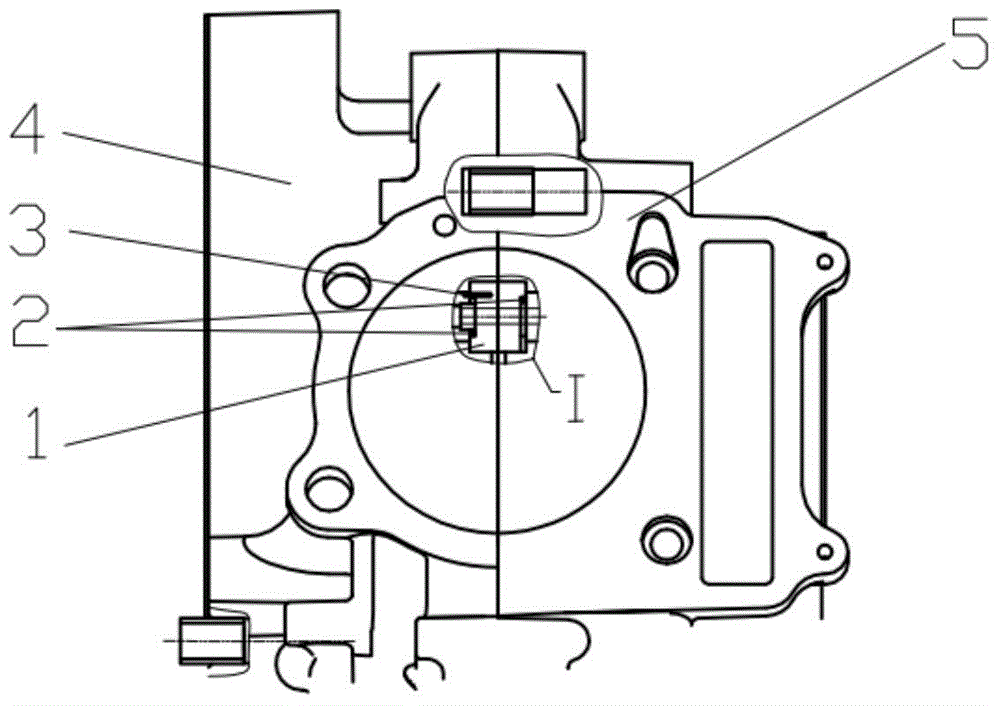

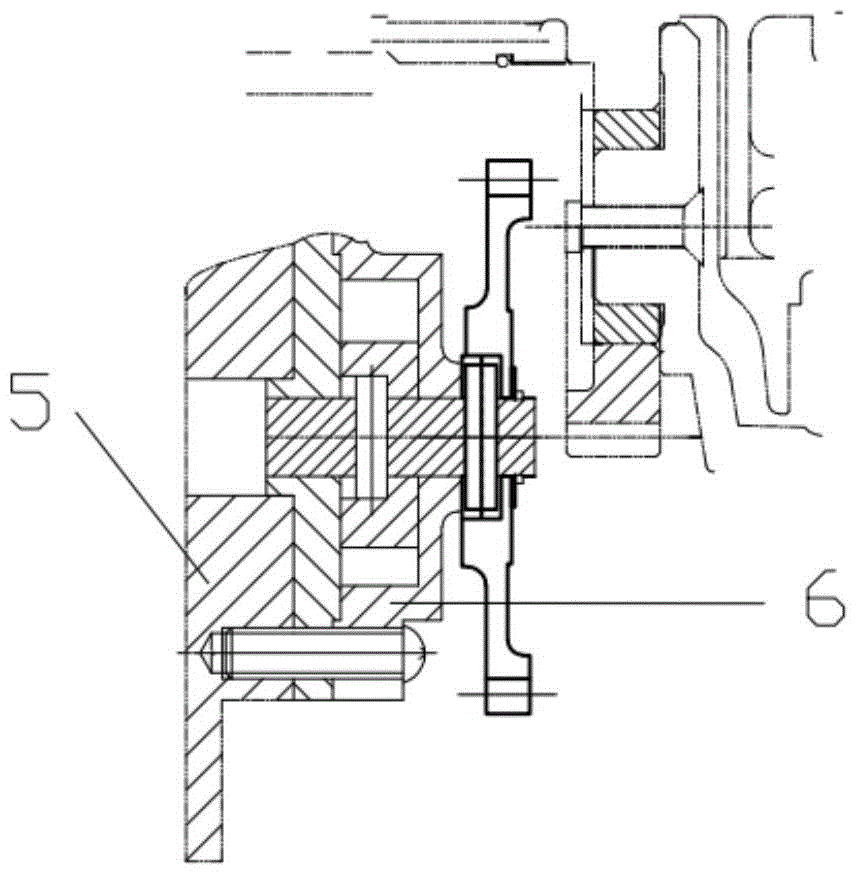

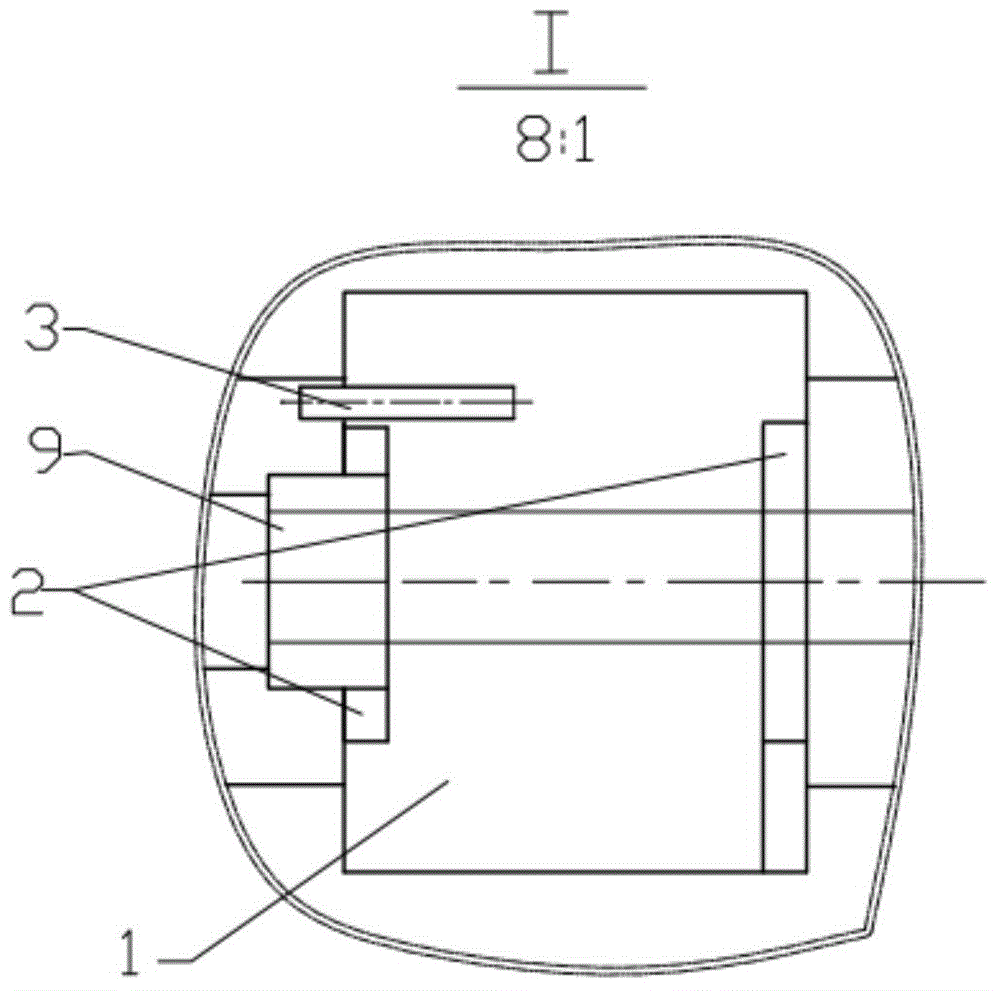

[0015] Such as figure 1 , figure 2 As shown, the invention includes: a left box body 4, a right box body 5, an oil pump combination 6 and a fuel injection nozzle, and the shown left box body 4 and the right box body 5 are fixed by closing bolts 9 to realize the injection The mouth combination 1 is installed between the left box body and the right box body. The fuel injection nozzle seat holes are set on the left box body and the right box body, and the driving pin 3 mounting holes are set on the left box body, and the seat platform of the fuel injection nozzle is inserted into the fuel injection nozzle seat hole. Inside, adjust the angle of the fuel injector so that the fuel injection port of the fuel inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com