Reliability test device and reliability test method for numerical control machine hydraulic system

A technology of hydraulic system and test device, which is applied in the test of fluid pressure actuation system, fluid pressure actuation device, mechanical equipment, etc., can solve the problem of lack of reliability test device and reliability test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

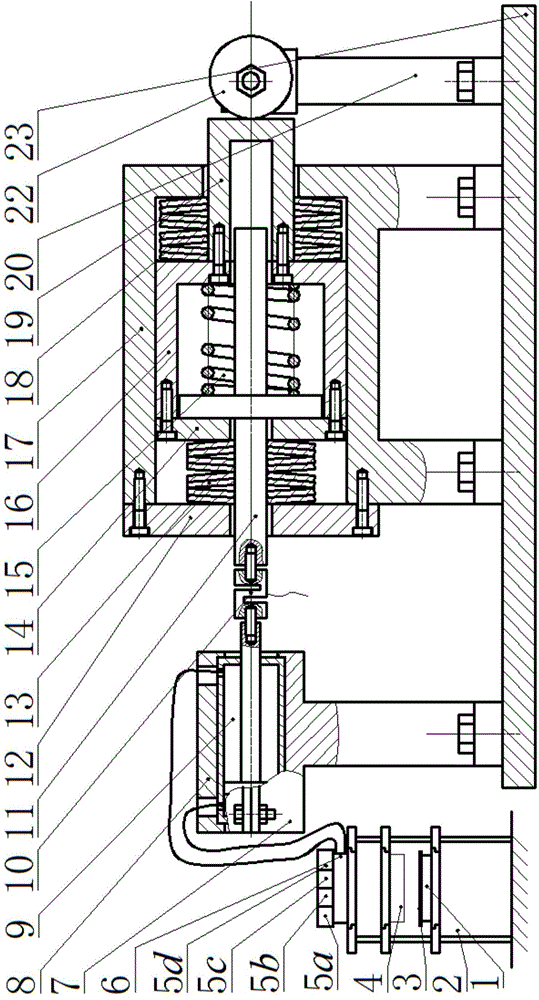

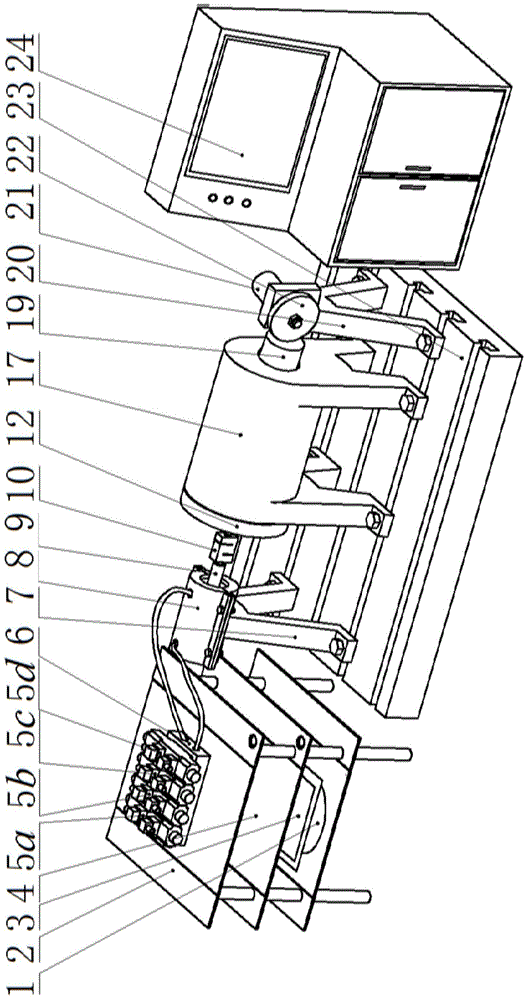

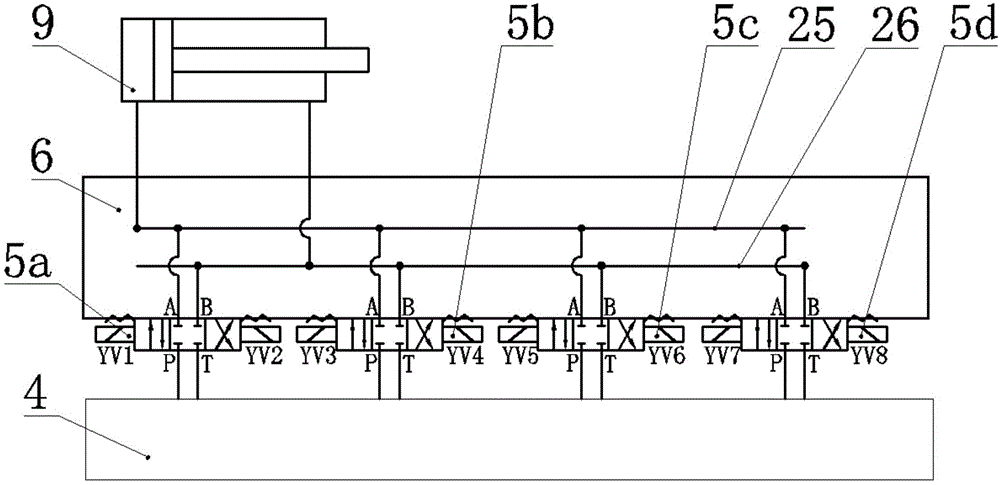

[0068] The present invention is described in detail below in conjunction with accompanying drawing:

[0069] Practice has proved that the frequent failure parts of the hydraulic system of CNC machine tools are oil pipes and hydraulic components. The typical failure modes are: oil leakage, blockage, and insufficient output pressure. Conduct reliability screening or improvement. According to the requirements of the reliability test, it is necessary to simulate the real working conditions of the hydraulic system as much as possible. At the same time, due to the long time of the reliability test, manual methods cannot be used for test observation, so the test device is required to be able to run automatically, automatically detect faults and alarm . The hydraulic system of CNC machine tools often has more than one branch, but when testing, it can only be tested in a single way, and there must be no influence between the branches. It meets the reliability test of multi-branch hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com