Straw coal gasification warming stove

A technology for coal gasification and heating stoves, which is applied to household stoves/stoves, stoves/stoves with hot water devices, heating methods, etc. It can solve the problem of improving fuel combustion efficiency and purifying flue gas and soot. Good, increase the use cost and other issues, to achieve good flue gas purification effect, low use cost, and fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

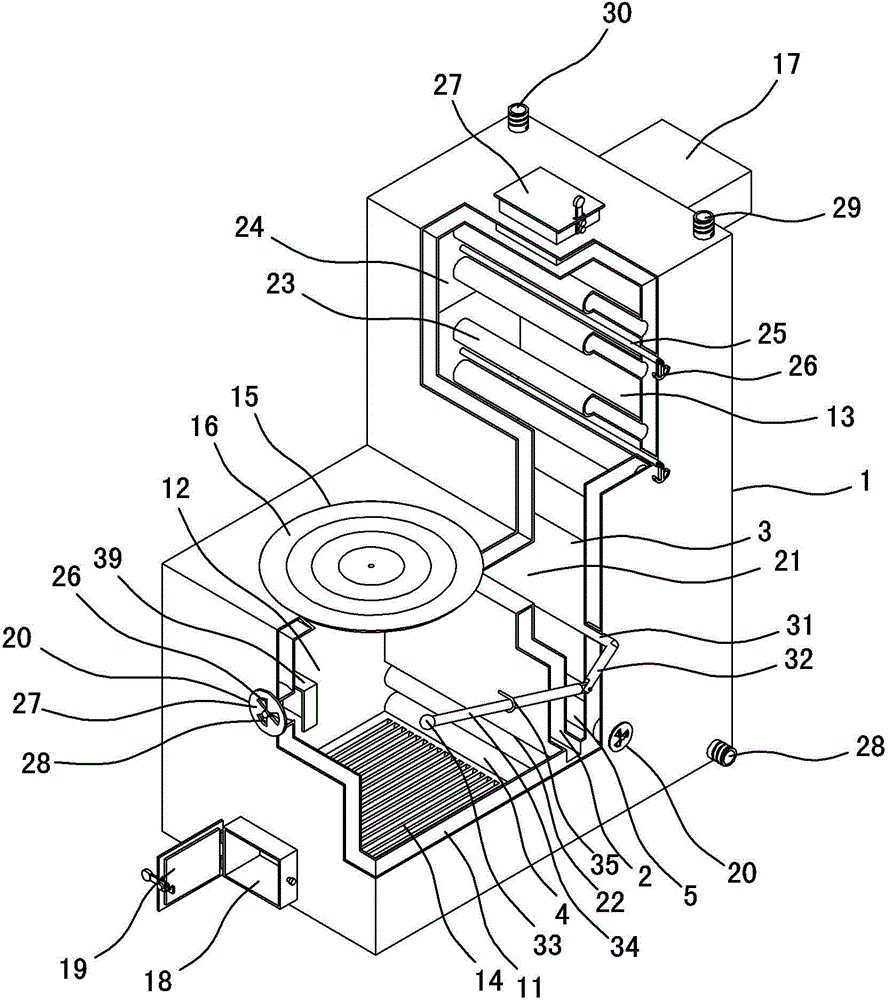

[0007] Such as figure 1 As shown, it includes a furnace body 1 with water jackets 11 respectively provided on the upper wall and surrounding walls, and a first combustion chamber 12 and a second combustion chamber 13 inside, and a fire grate is arranged below the first combustion chamber 12. 14. The top wall of the furnace body 1 above the first combustion chamber 12 is provided with a furnace cover opening 15 and a furnace cover 16 is installed. The rear wall of the furnace body 1 above the second combustion chamber 13 is provided with a smoke outlet and connected to a The chimney 17 outside the furnace body 1, the lower part of the front wall of the first combustion chamber 12 front portion of the furnace body 1 is provided with a furnace mouth 18 and is hingedly equipped with a furnace door 19, and the front wall of the furnace body 1 above the furnace mouth 18 is provided with a ventilator. The air regulating valve 20 is installed at the mouth of the furnace body 1, and ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com