Universal test fixture

A technology of test fixtures and test pieces, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of different installation sizes of ear-type test pieces, difficult storage and management of test fixtures, and increased time for disassembling and assembling fixtures, etc., to achieve The effect of saving production cost and processing cycle, simple structure, and reducing disassembly and assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] Hereinafter, the present invention will be further described in detail through specific embodiments.

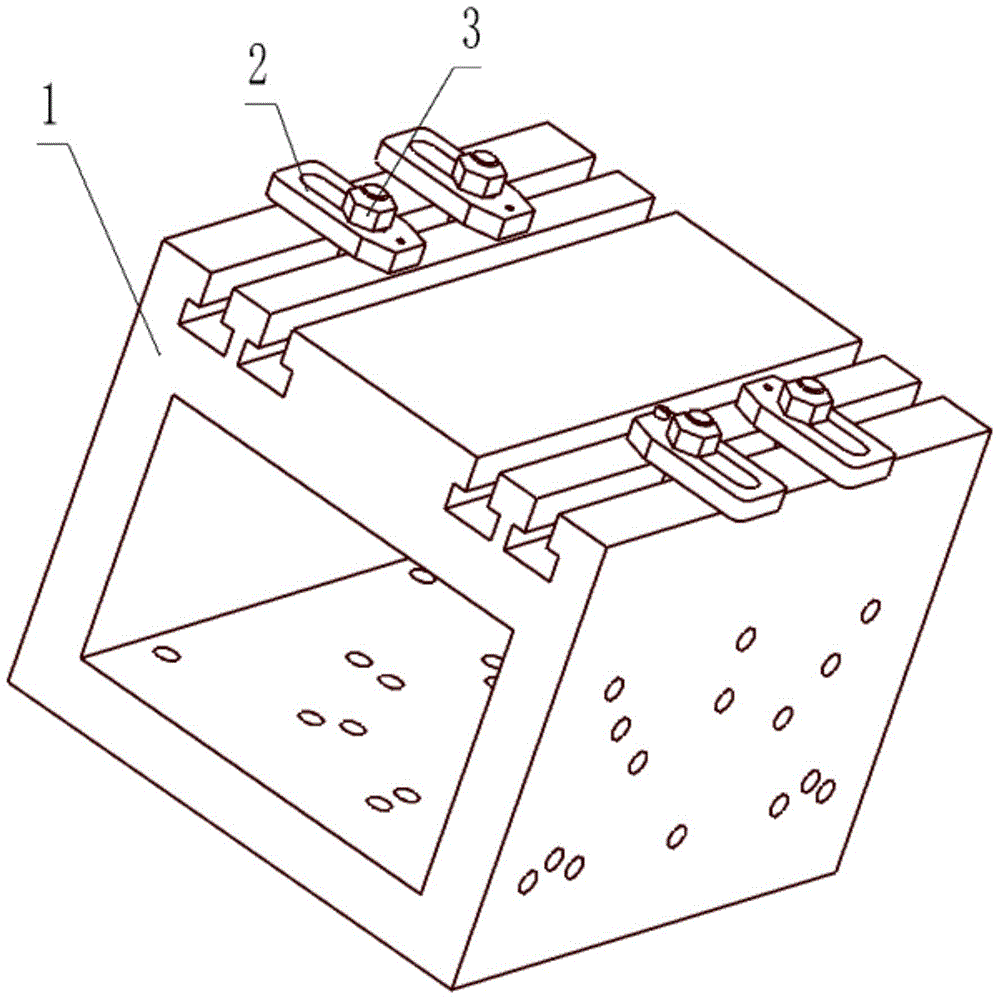

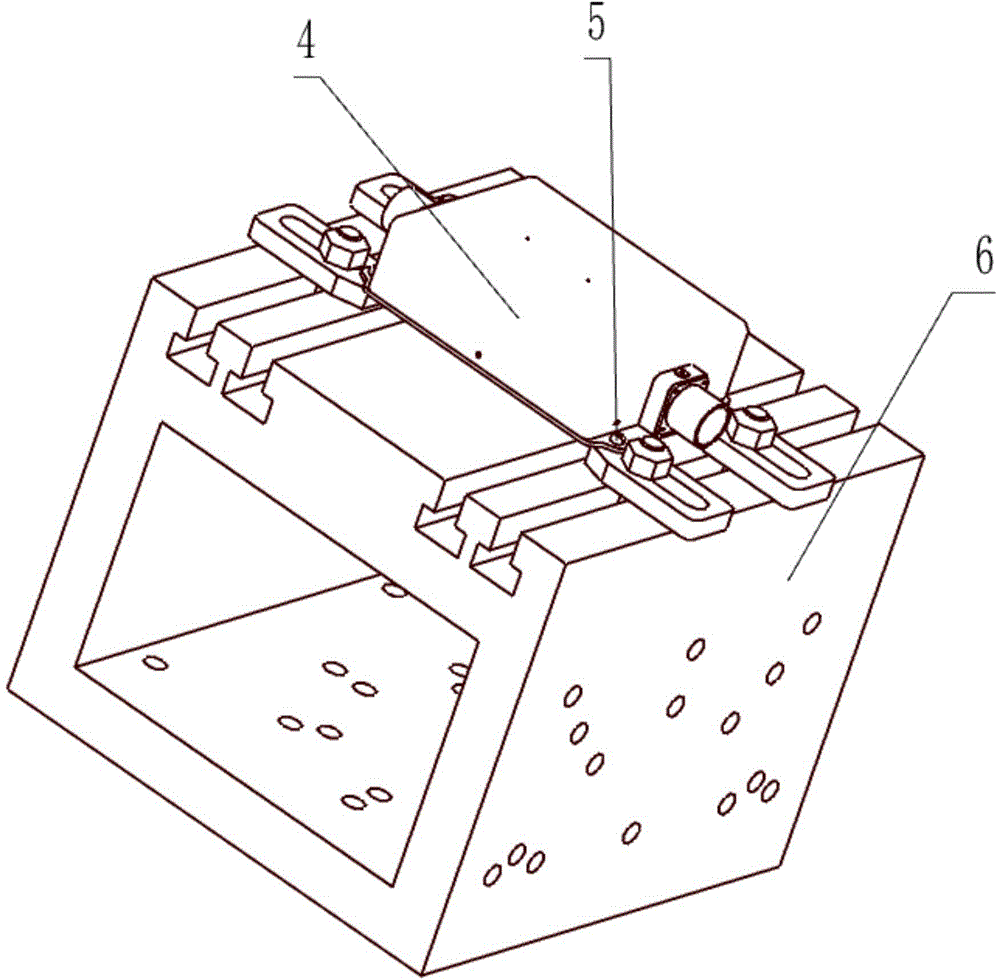

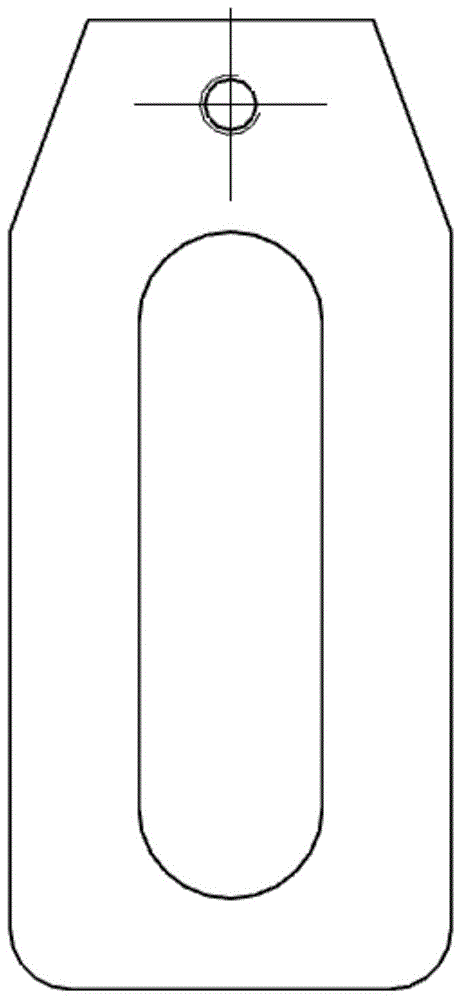

[0012] See also figure 1 , figure 2 with image 3 ——The schematic diagram of the structure of the invention, the schematic diagram of the installation of the test piece and the schematic diagram of the pressure plate. The base 1 designed in the present invention is fixed on the test bench by fasteners to complete the installation of the test fixture. The test piece 4 is fixed on the pressure plate 2 by a fastener 5, and the pressure plate 2 is fixed on the base 1 by a fastener 3. The fastener 3 can be moved and adjusted in the T-slot of the base 1 to meet the transverse installation distance of the test piece, and the pressure plate can be adjusted to meet the longitudinal installation distance of the test piece through the waist-shaped hole of the pressing plate 2. After the adjustment is completed, tighten the fastener 3 to complete the installation of the test piece...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap