System and method for testing temperature-varying micro-nanometer indentations with vacuum protection characteristics

A test system and protective technology, applied in the field of variable temperature micro-nano indentation test system, can solve problems such as limitations, achieve the effect of ensuring loading accuracy, meeting the requirements of large loading stroke indentation, broad development prospects and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

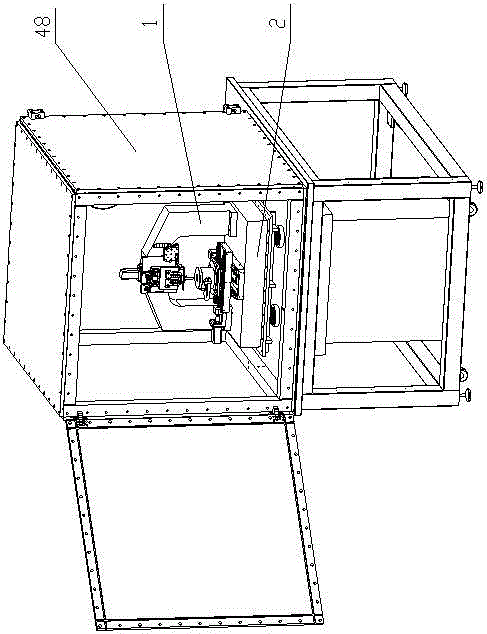

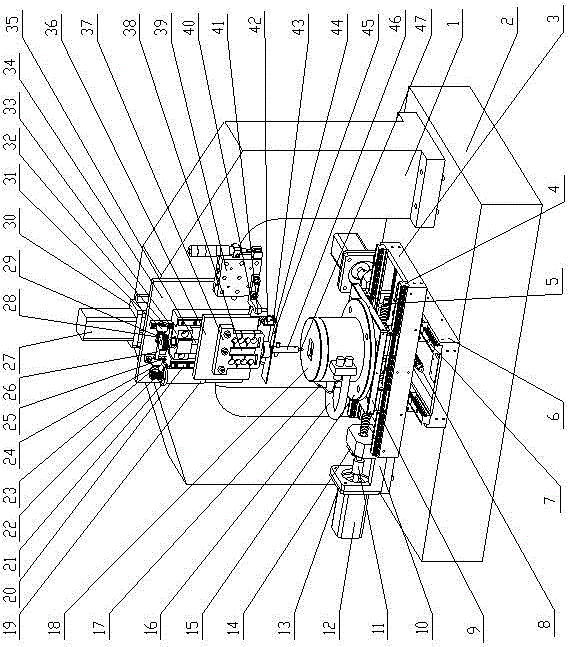

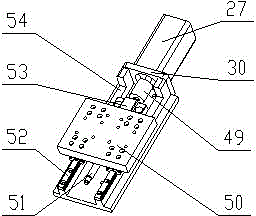

[0066] see figure 1 and figure 2 As shown, the present invention provides a temperature-variable micro-nano indentation test system with vacuum protection, which consists of a vacuum chamber system, a Z-axis direction macro-motion adjustment mechanism, a Z-axis large-stroke precision press-in drive unit, and a Z-axis small-stroke precision press. It is composed of input drive unit, displacement signal detection unit, load signal detection unit, temperature loading and detection unit and X-Y precision positioning platform. The vacuum chamber system 48 provides a vacuum atmosphere for the mechanical loading part; the Z-axis direction macro-adjustment mechanism is assembled on the marble support seat 1 . The Z-axis large stroke precision press-in drive unit is installed on the macro adjustment mechanism, mainly composed of servo motor Ⅰ19, worms Ⅰ, Ⅱ22, 29, worm wheels Ⅰ, Ⅱ23, 28 and screw nut Ⅱ35 and other mechanisms. The Z-axis small-stroke precision press-in drive unit is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com