Method of automatically generating layering exploded view

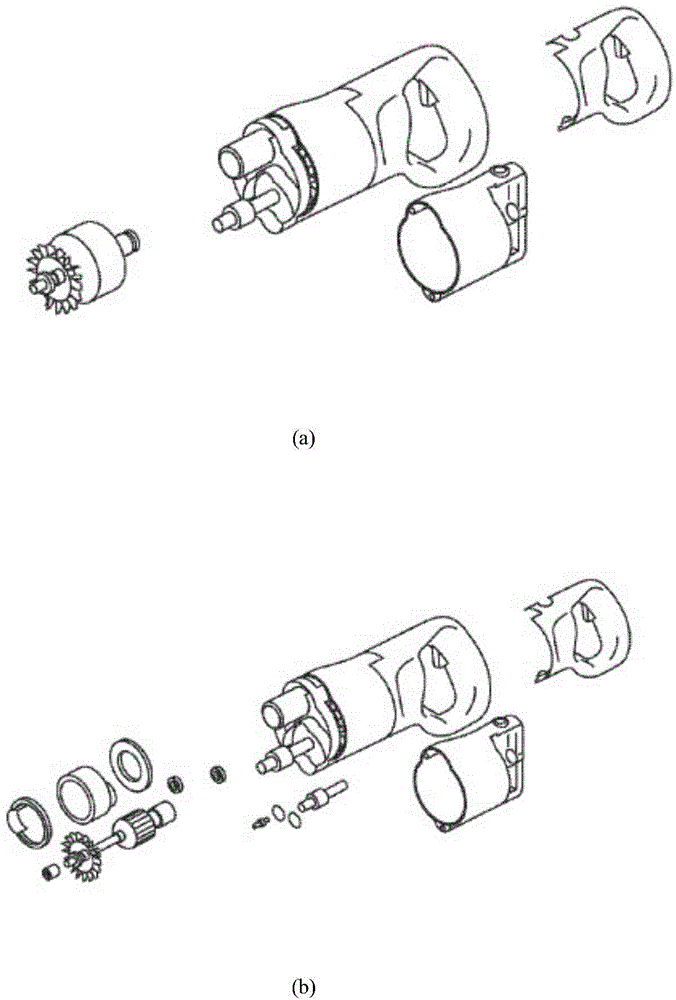

An automatic generation and hierarchical technology, applied in the field of exploded diagrams, can solve problems such as inability to apply complex products, inapplicability to three-dimensional space, and time-consuming processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

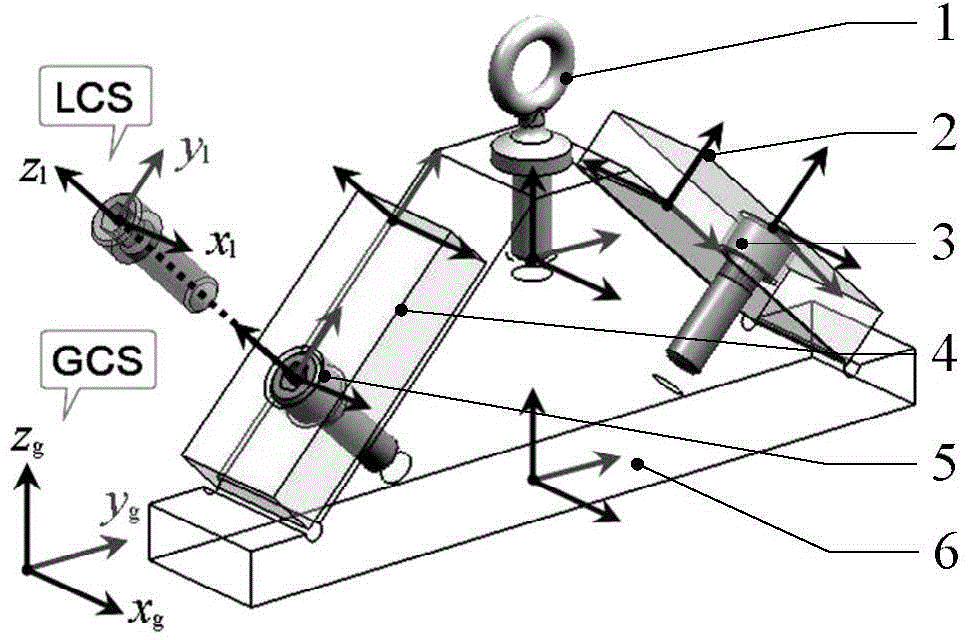

[0120] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0121] A method to automatically generate hierarchical exploded graphs, such as Figure 15 shown, including the following steps:

[0122] Step 1: Obtain 3D CAD assembly drawings;

[0123] Step 2: extract the constraint relationship between the parts of the assembly in the 3D CAD assembly drawing, and obtain the contact-connection matrix and the extended interference matrix;

[0124] Step 2.1: Generate a contact-connection matrix based on the static gap analysis. In this matrix, when there is contact-connection interference between two parts, the corresponding matrix element is assigned a value of 1;

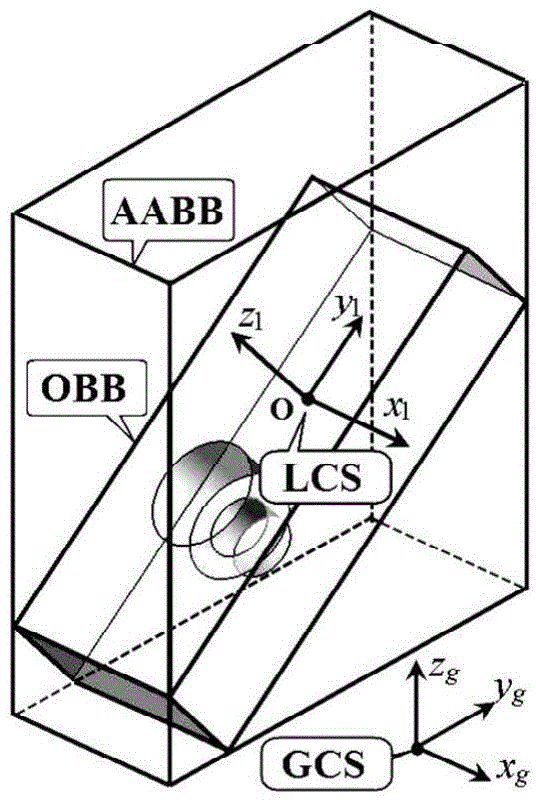

[0125] Step 2.2: cyclically perform interference detection according to +x, +y, +z, / x, \x, / y, \y, / z, \z directions, and generate an extended interference matrix (Extended interference matrix, EIM);

[0126] The automatic gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com