Virtual assembly system for land drilling rig and operation method thereof

A virtual assembly and land-based technology, applied in the field of land drilling rig virtual assembly system and its operation, can solve problems such as limited practical opportunities, difficulty in operators, loss of life and property, etc., and achieve the goal of improving work flow, reducing workload and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

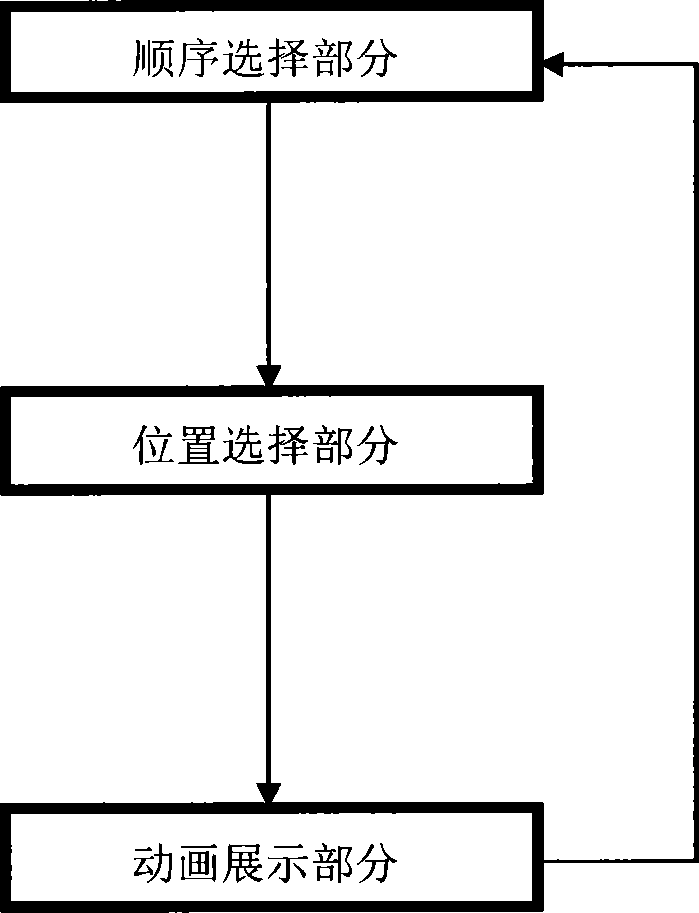

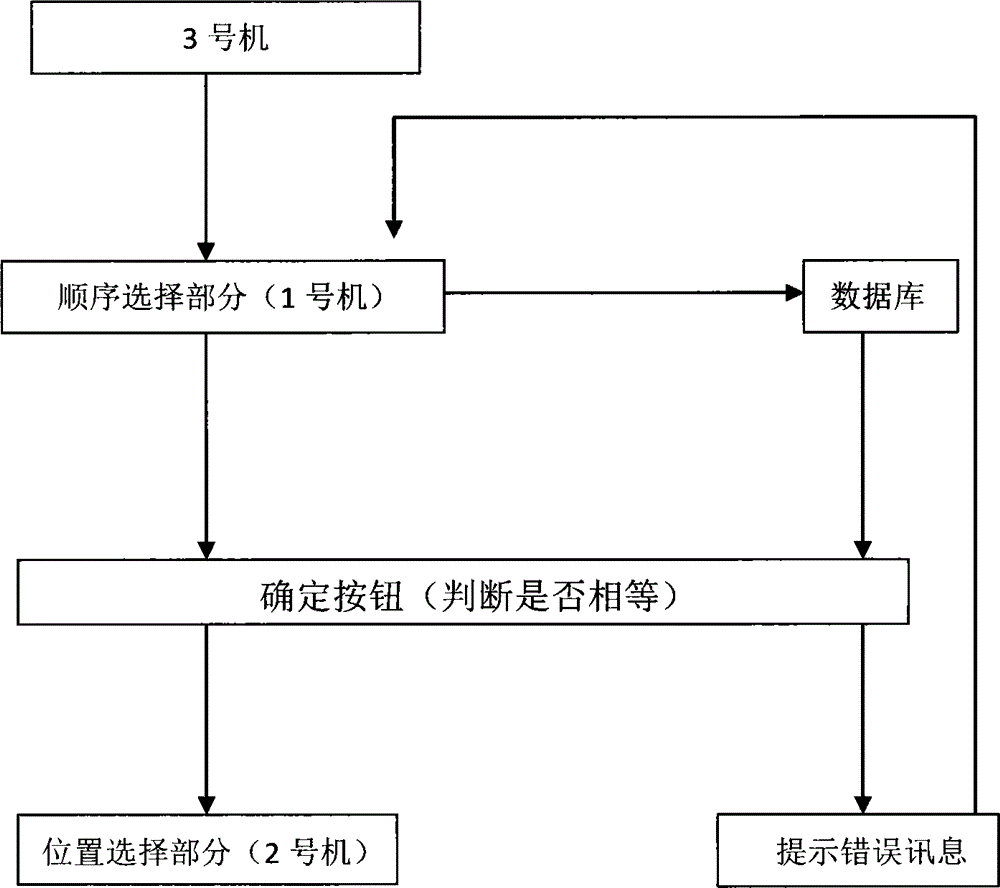

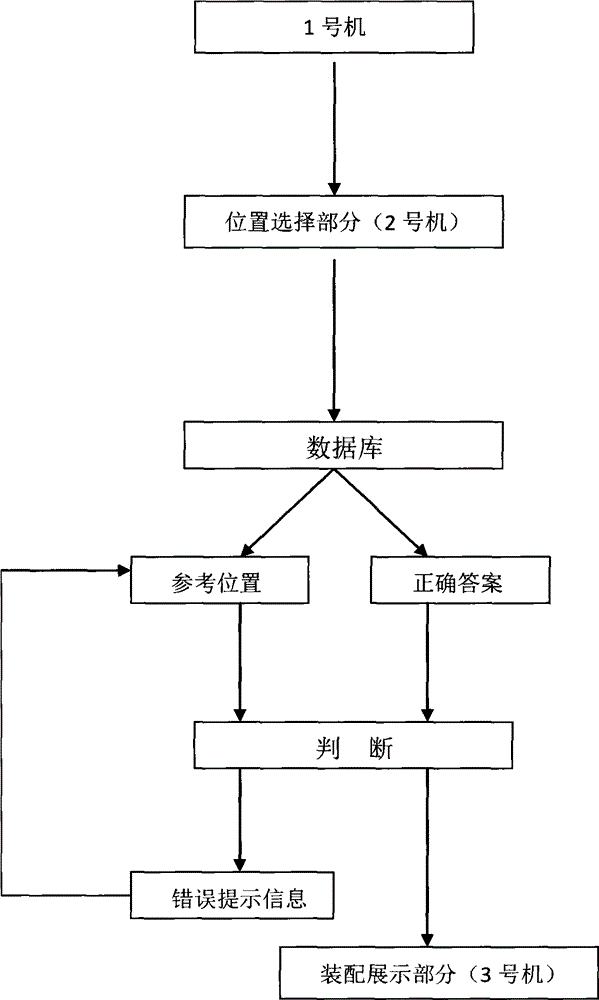

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings: a virtual assembly system for a land drilling rig, which includes computer No. 1 as a sequence selection module, computer No. 2 as a position selection module, and No. 3 ring screen as an assembly process display module The animation machine and the projection ring screen that is connected with the animation machine to output animation, as attached figure 1 Shown:

[0023] Wherein, there is a virtual simulation main module in the sequence selection module, including: a three-dimensional model storehouse, a three-dimensional drive engine, a database and a human-computer interaction module; the three-dimensional model storehouse is a three-dimensional model storehouse storing an environment three-dimensional model and a land drilling rig three-dimensional model, The three-dimensional driving engine is used to drive the three-dimensional model and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com