Self-tightening type feeder line connector

A self-tightening, feeder technology, applied in the field of feeder joints, can solve the problems of many tools, troublesome, delayed construction period, etc., to achieve the effect of firm connection, reduced use cost and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

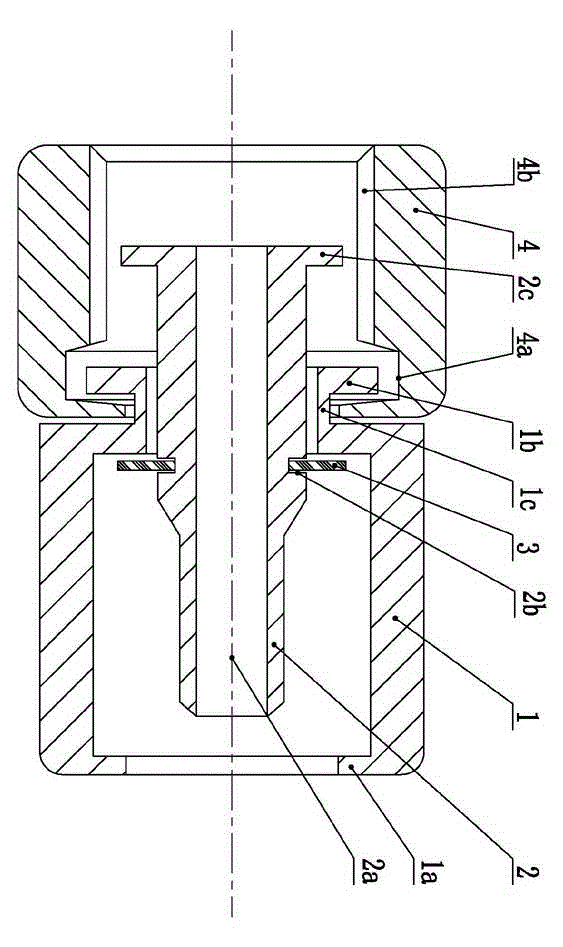

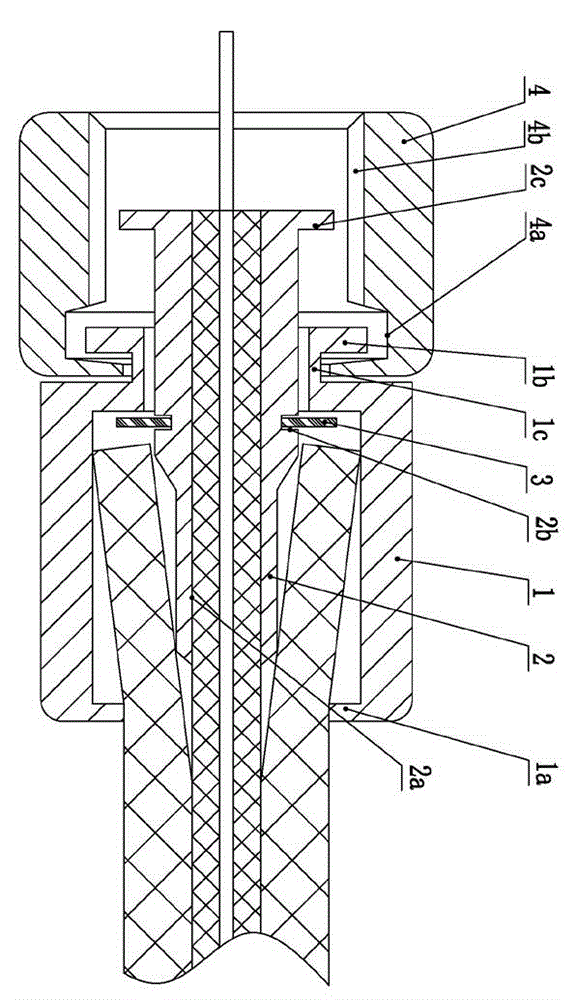

[0013] Such as Figure 1-2 As shown, a self-tightening feeder joint is assembled by a nut 4, a cylindrical copper sheath 1, and a movable inch core 2 with a core hole 2a; the nut 4 has a matching thread for direct connection with the equipment 4b, the groove 4a close to the rear end of the nut 4; the outlet cylinder 1c of the copper sheath 1 is a cylindrical structure arranged in the central area of the outlet end face of the copper sheath 1 and extending inwardly of the nut 4 along the axial direction. The outer circumference of the end of the outlet cylinder 1c of the sleeve 1 is provided with a ring-shaped flange 3 1b, and the ring-shaped flange 3 1b is movably clamped in the groove 4a in the nut 4, and the entrance end of the copper sheath 1 is provided with a ring of edge An annular flange-1a extending radially inwards, the inner diameter of the annular flange-1a is greater than the outer diameter of the inlet end part on the movable inch core 2; the movable inch core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com