Feed-forward decoupling vector control method for inverter running with output reactor

A technology of vector control and feedforward decoupling, applied in the field of feedforward decoupling vector control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

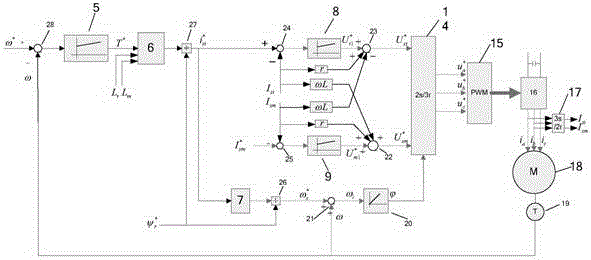

[0051] refer to Figure 5 The shown feed-forward decoupling vector control block diagram of the frequency converter with output reactor operation, the actual speed ω of the motor 18 (the angular frequency of the current flowing through the three-phase AC reactor) is obtained through the speed measuring device 19, and ω is related to the controller's Motor command speed ω * Compare by the first comparator 28, the ω obtained after the first comparator 28 compares and ω * After the speed difference between the two passes through the speed regulator 5, the torque command T is obtained * . Torque command T * with the magnetizing inductance L of the motor 18 m and rotor inductance L s After calculating in the torque current calculator 6, then through the first divider 27 and the rotor flux linkage value By dividing, the T-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com