Flexible circuit board and manufacturing method thereof

A production method and circuit board technology, which are applied in the direction of multi-layer circuit manufacturing, printed circuit components, printed circuit structural connection, etc. The effect of good elasticity, good expansion and contraction, and consistent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] see Figure 1 to Figure 8 , the embodiment of the present invention provides a method for manufacturing a flexible circuit board 100, including steps:

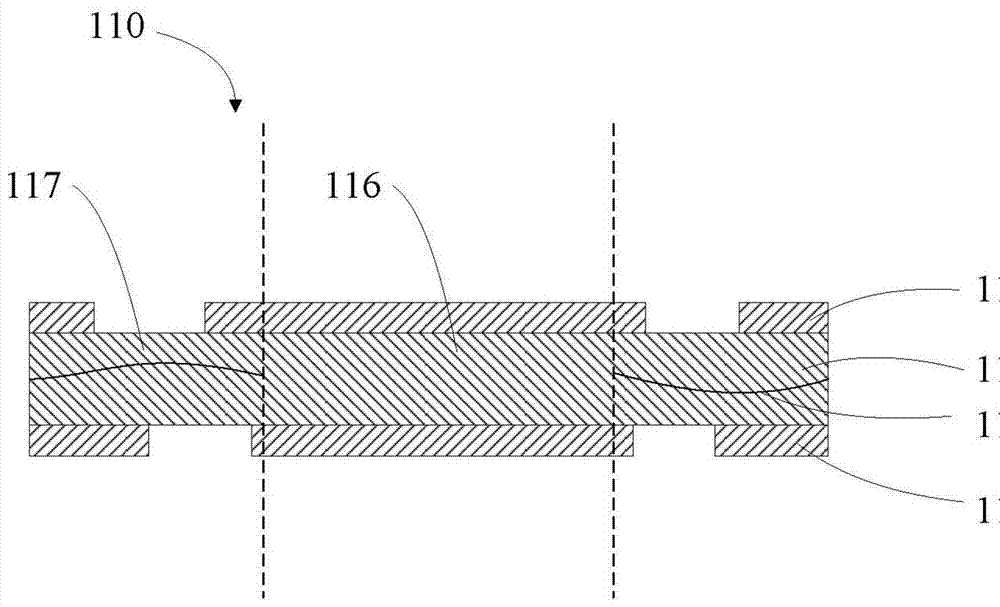

[0020] For a first step, see figure 1 , providing a circuit core board 110

[0021] The circuit core board 110 includes a first insulating substrate 113 and a first conductive circuit pattern 111 and a second conductive circuit pattern 112 formed on both sides of the first insulating substrate 113, and the first insulating substrate 113 has An intermittent glass fiber cloth layer 114 and an insulating colloid, and the insulating colloid is integrally connected to the glass fiber cloth layer 114 . In this embodiment, the thickness of the glass fiber cloth layer 114 is less than or equal to 20 microns.

[0022] In the area where the circuit core board 110 only has insulating colloid and does not contain a glass fiber cloth layer, a bending area 116 is formed; in the area where the circuit core board 110 has insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com