Method for laser welding and welded metal using the same

A laser welding and laser technology, used in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of laser welding of difficult-to-weld blank components, and achieve the effect of excellent welding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Cold-rolled steel sheets (CR) and galvanized steel sheets (GI) having the compositions (wt%, the remainder being iron and unavoidable impurities) and thicknesses shown in Table 1 below were prepared, respectively.

[0063] [Table 1]

[0064]

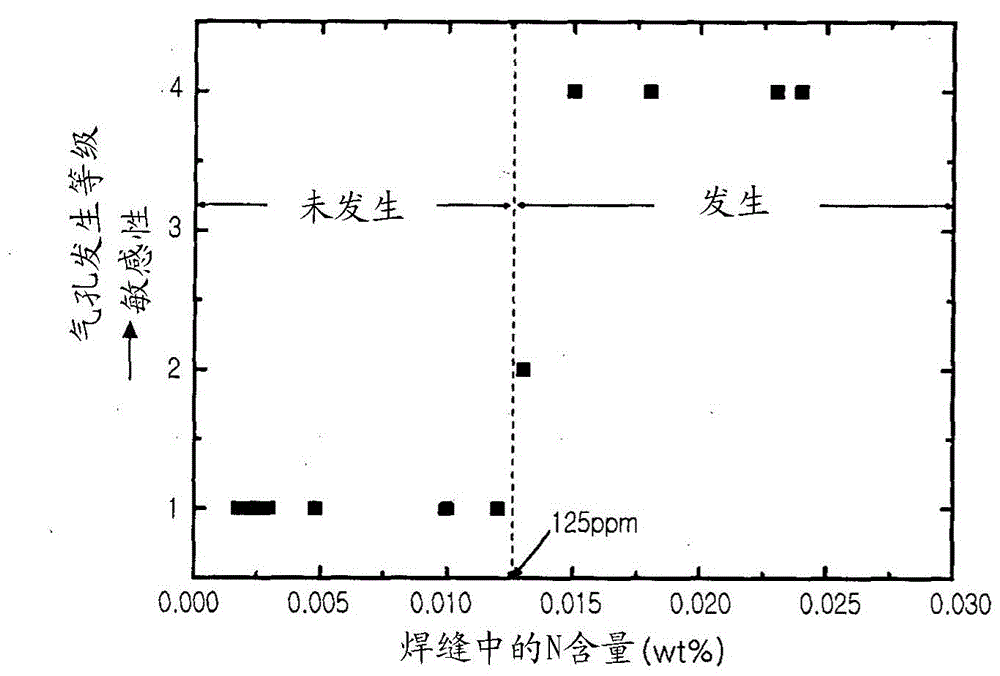

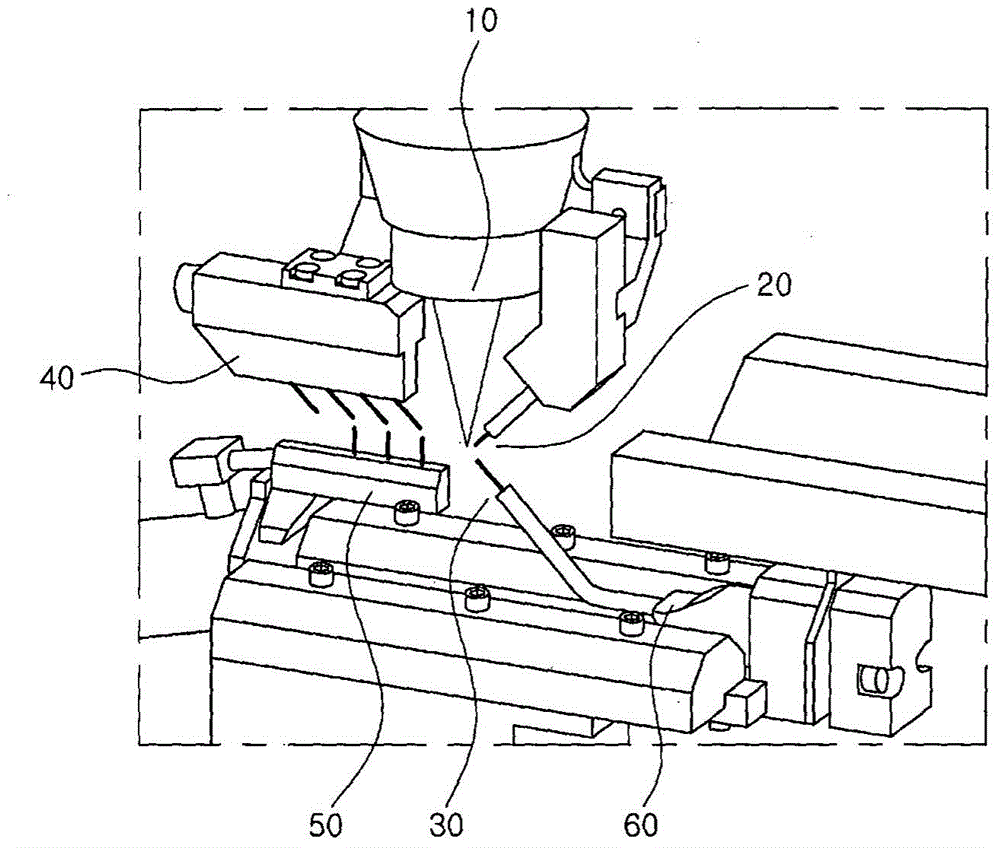

[0065] Laser welding was carried out using cold-rolled steel sheets and galvanized steel sheets of A and B. At this time, using 6kW of CO 2 The laser welder performed laser welding, and performed butt welding under conditions such as a laser output of 6 kW and a welding speed of 2 m / min that the formation of porosity was relatively significant by a preliminary test.

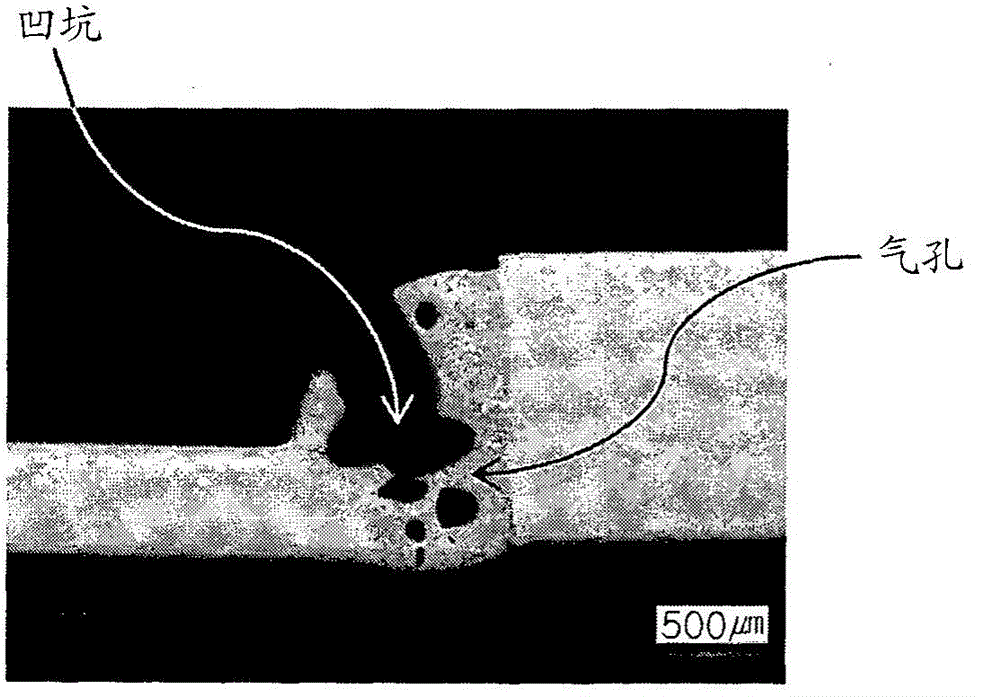

[0066] Porosity defects of laser welded seams were determined under KS B0845. When the steel material has a thickness of 10 mm or less, it is classified as grade 1 if the defect point within the visible test area of 10×10 mm is 1 or less; if the defect point is 3 or less, it is classified Class 2; Class 3 if the defective point is 6 or less; and Class 4 if th...

Embodiment 2

[0078] By using CR-A (thin plate) and CR-B (thick plate) in Table 1, when performing welding, change the distance from the interface to the thick plate during laser irradiation and change the welding heat input under the conditions of Table 3 below In the case of , the welding defect and crack occurrence rate of the weld was measured, and the results are shown in Table 3.

[0079] Welding was performed by supplying helium gas at a flow rate of 20 l / min to the laser irradiated part and the rear of the laser irradiated part, and welding heat input was controlled by changing the laser output and welding speed.

[0080] In Table 3, welding defects were observed by paying attention to the shape of the bead, and the sag was determined by setting a standard case in which the welded metal part sags 0.1 mm compared to the base material. In addition, meltdown refers to a case where a sinking phenomenon is a main cause of molten metal dripping and widely formed voids. The cracking incid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com