Cooling element for a melting furnace

A technology for cooling elements and furnaces, which is applied in the direction of furnace cooling devices, furnace cooling, furnace components, etc., can solve problems such as heat transfer effects, and achieve the effects of optimized manufacturing methods, durable welds, and reliable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

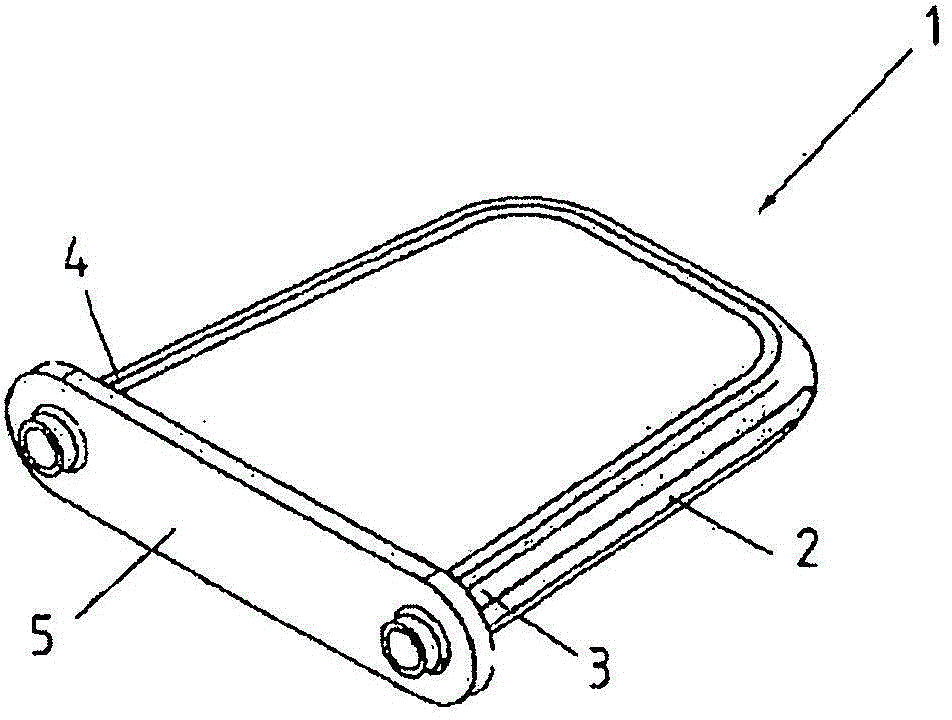

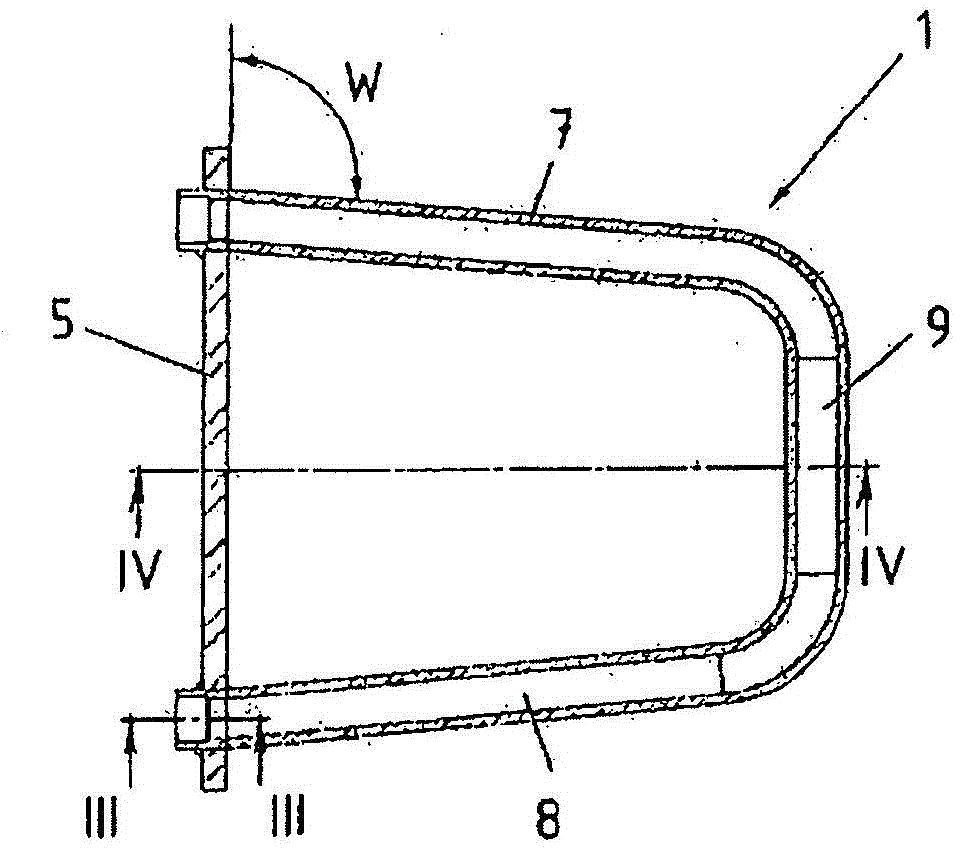

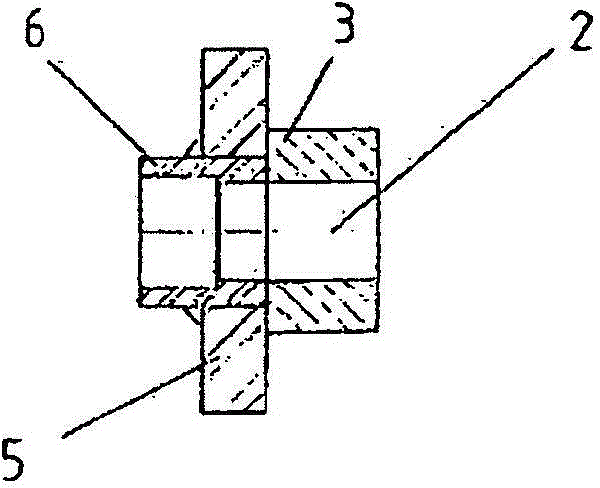

[0045] figure 1 A cooling element 1 is shown for installation into the wall of a furnace. The cooling element 1 comprises a U-shaped curved cooling tube 2 which, in a manner not shown, passes through the furnace shell and protrudes into the furnace interior. The cooling tube 2 has two ends 3 , 4 which are connected to a common plate-shaped support element 5 . Depend on figure 2 and 3 It can be seen that the cooling tube 2 does not pass through the carrier element 5 with its end 3 , but is only fastened to the opening of the carrier element 5 . A socket 6 is fastened to this opening of the carrier element 5 by welding. The connection piece 6 is used for coupling with other pipe sections in a manner not described.

[0046] In the exemplary embodiment, the connecting piece 6 is made of steel, while the cooling pipe 2 is made of copper material. Firstly, the connecting pipe 6 is connected with the cooling pipe by welding. This can preferably be achieved by friction welding...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap