EO sterilized product forced desorption device and forced desorption method

A forced desorption and desorption technology, applied in water supply installations, sanitary equipment for toilets, buildings, etc., can solve problems such as differences in EO residues, and achieve the effect of improving safety and realizing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

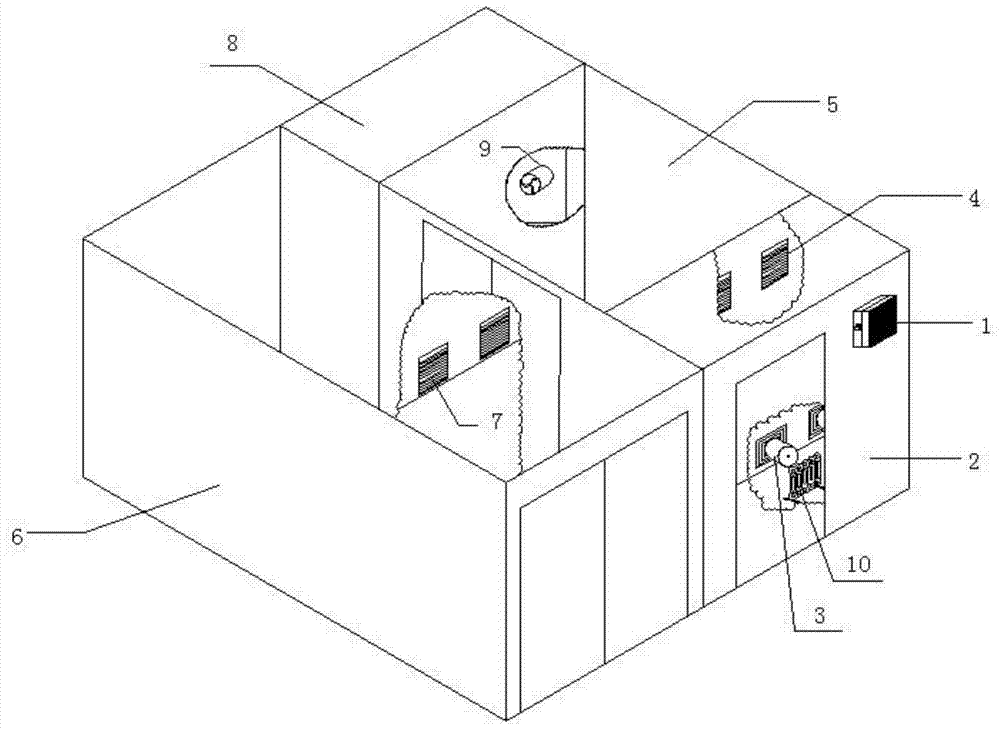

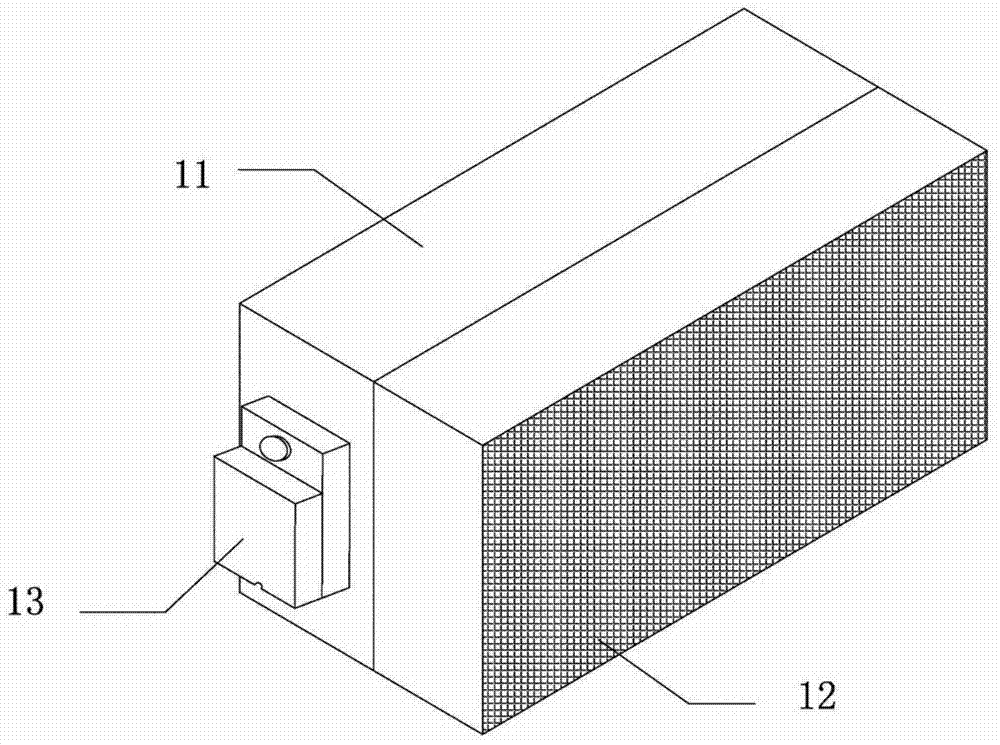

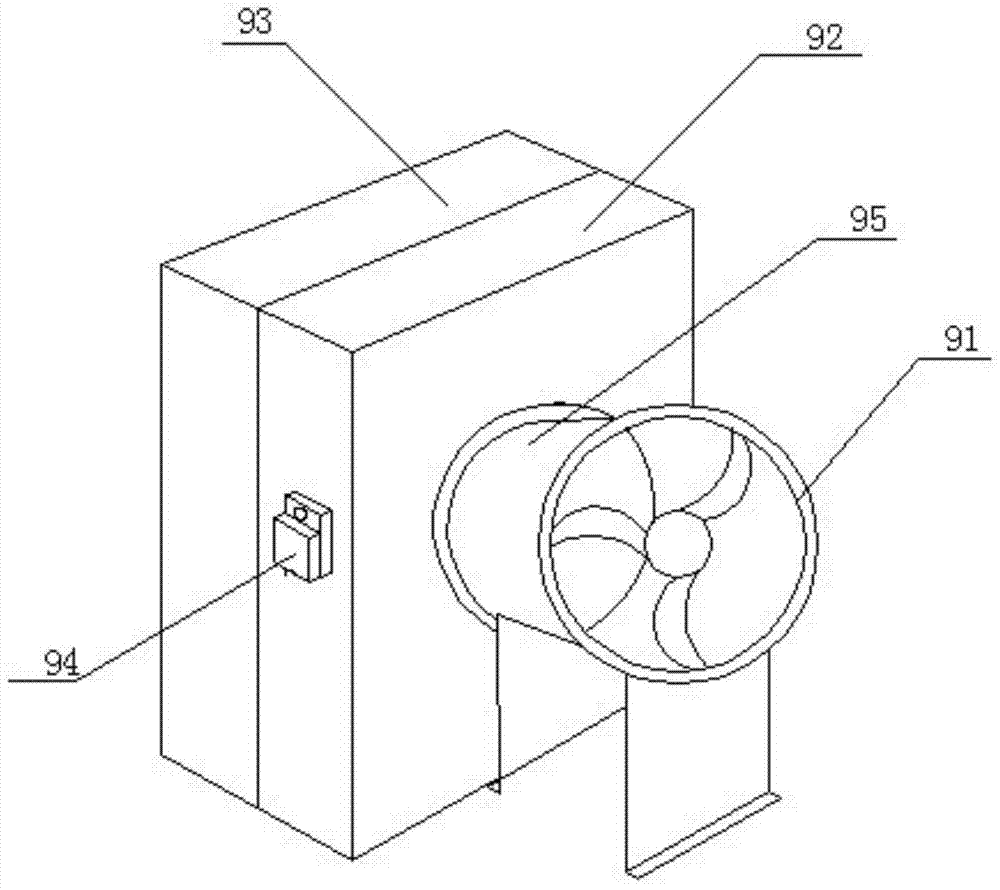

[0027] Such as figure 1 Shown, a kind of EO sterilized product forced desorption device of the present invention, it comprises heating air supply room 2, desorption room 5, exhaust air room 8, unpacking room 6; Desorption room 5 is connected with unpacking room 6, and between the two There is an entrance and exit door; the heating air supply room 2 is connected to the desorption room 5, and a blower fan 3 and a return air guide window 4 are arranged on the partition wall between the heating air supply room 2 and the desorption room 5. Among them, a row of return air The diversion window 4 is arranged on the upper part of the partition wall, and the three blowers 3 are arranged on the middle and lower part of the partition wall; on the partition wall between the desorption room 5 and the exhaust room 8, an exhaust device 9 and an exhaust guide window are arranged. 7. Among them, the air exhaust device 9 is arranged on the upper part of the partition wall, and a row of exhaust ...

Embodiment 2

[0067] Next, the function of the desorption device described in Example 1 is verified by desorption of EO sterilized products.

[0068] The sterilization process of our company's products is entrusted to an external company, and the method of "over" sterilization is adopted. The effectiveness of product sterilization has been verified and confirmed. The inner packaging of the product is in the form of a blister bowl and air-permeable paper sealing. The material used in the product is silicone rubber, which has strong adsorption to EO. During the sterilization process, the product has been desorbed by "vacuumizing" and ventilating, but there are still EO residues inside the product. Therefore, it is called "EO sterilized product". Now use the desorption device described in Example 1 to carry out forced desorption to the above-mentioned EO sterilized product.

[0069] Adopt the desorption device described in embodiment 1 to carry out the processing method of forced desorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com