Trash sorting device and method

A garbage and sorting technology, which is applied in the direction of chemical instruments and methods, solid separation, and separation of solids from solids with airflow, which can solve the problems of poor separation efficiency and separation effect of wind separation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

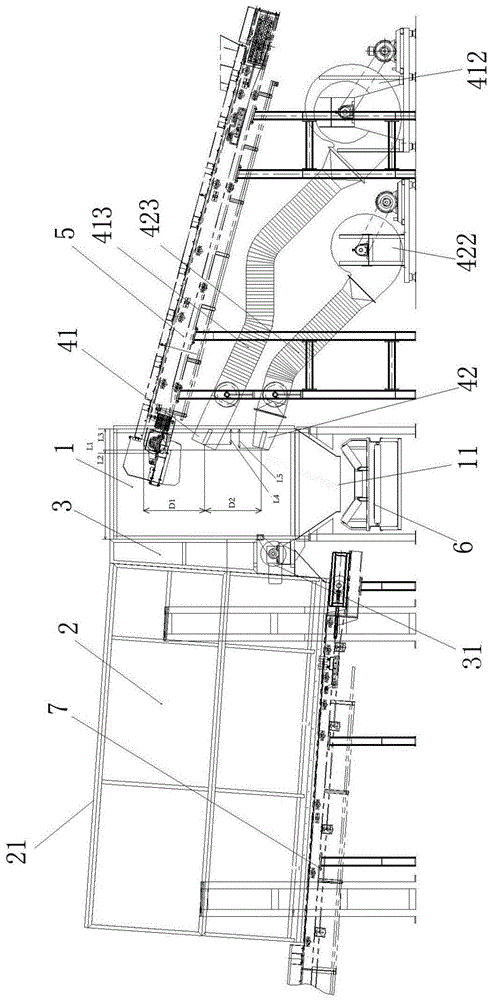

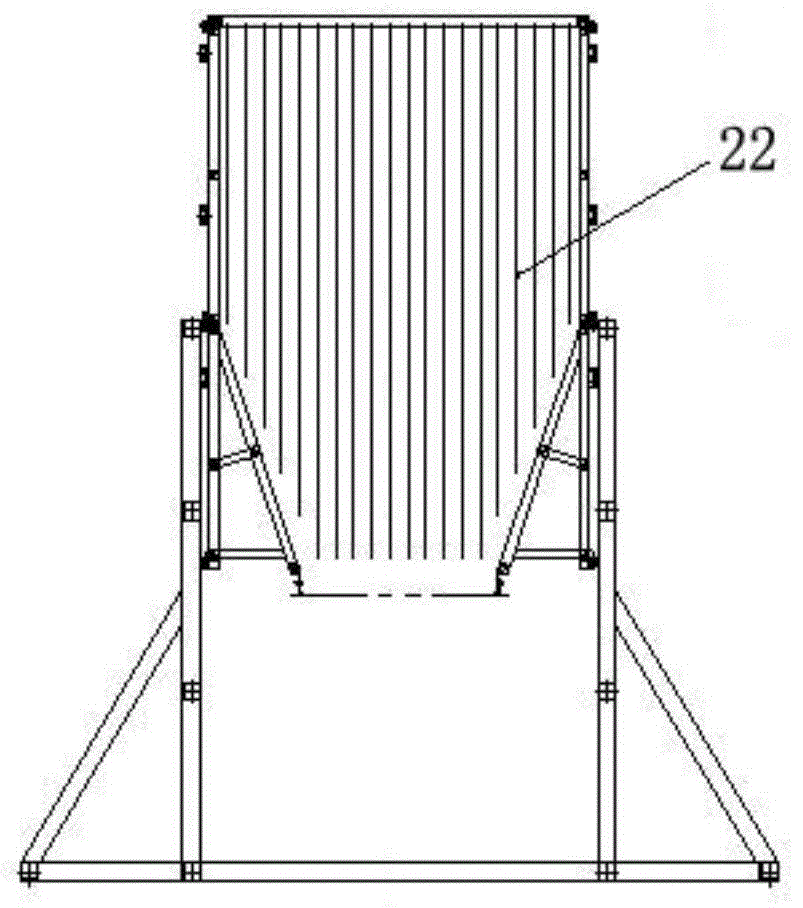

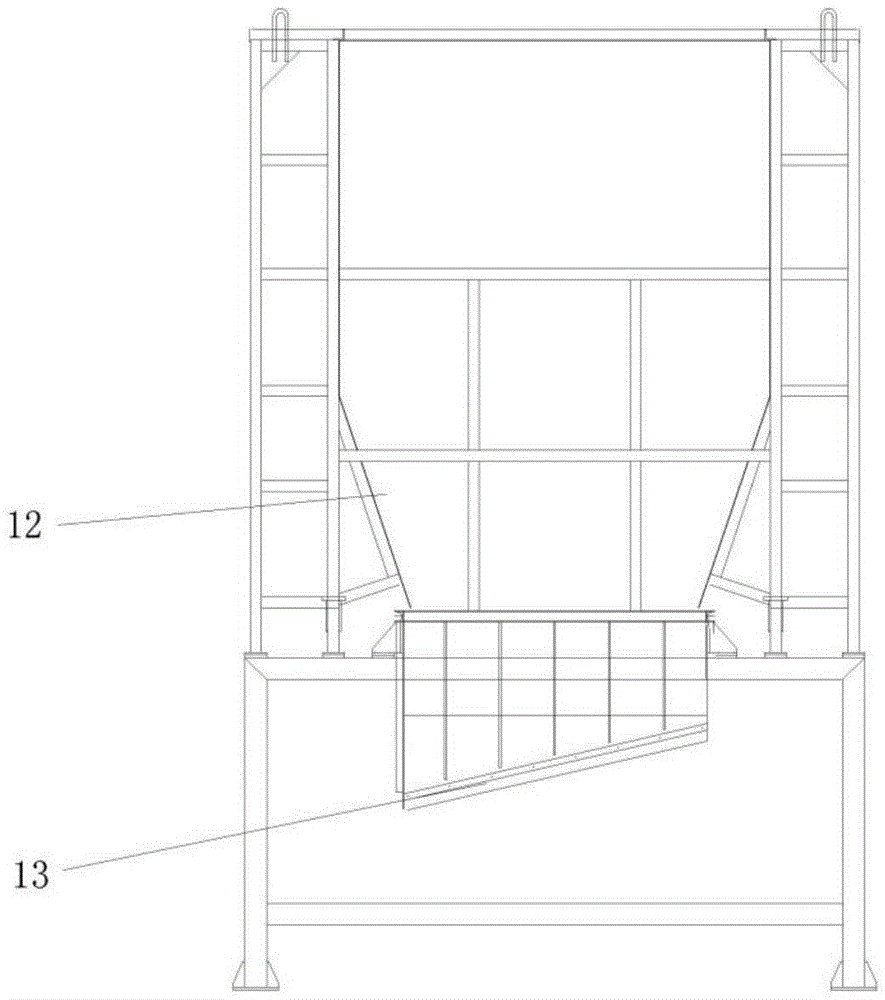

[0030] This embodiment provides a garbage sorting device, such as Figure 1-3 As shown, it includes a heavy material bin 1 with a vertical movement space and a sealed top, and a light material bin 2 arranged on one side of the heavy matter bin 1 and communicated with the heavy matter bin 1 is arranged on the side of the heavy matter bin 1. The feed port on the warehouse 1, the feed conveying device 5 for conveying materials to the feed port, the main tuyere 41 arranged below the feed port, and the auxiliary tuyere 42 arranged below the main tuyere 41, the feed The main tuyere 41 and the auxiliary tuyere 42 are arranged side by side on the side of the heavy material bin 1 opposite to the light material bin 1 and communicate with the vertical movement space. The main tuyere 41 and the auxiliary tuyeres The tuyeres 42 are used to blow out the airflow to blow the light matter from the garbage material from the feed port into the light matter bin 2, and the lower end of the heavy m...

Embodiment 2

[0052] This embodiment provides a kind of garbage sorting equipment, which is a deformation on the basis of Embodiment 1. It differs from Embodiment 1 in that the angle formed by the central axis of the main tuyere 41 and the horizontal plane is 32°, and the auxiliary tuyere 42 The included angle formed by the central axis of the feed conveying device 5 and the horizontal plane is 26°; The vertical distance between the center of the main tuyere 41 end face and the center of the feed port end face is 580mm, the vertical distance between the center of the main tuyere 41 end face and the center of the auxiliary tuyere 42 end face is 680mm, and the length of the main tuyere 41 is 620mm, The width is 360mm, the length of the auxiliary tuyere 42 is 620mm, and the width is 210mm. The airflow velocity of the main tuyere 41 is 39m / s, and the airflow velocity of the auxiliary tuyere 42 is 30m / s.

Embodiment 3

[0054] This embodiment provides a kind of garbage sorting equipment, which is a deformation on the basis of Embodiment 1. It differs from Embodiment 1 in that the angle formed by the central axis of the main tuyere 41 and the horizontal plane is 35°, and the auxiliary tuyere 42 The included angle formed by the central axis of the feed conveying device 5 and the horizontal plane is 28°; The vertical distance between the center of the main tuyere 41 end face and the center of the feed port end face is 600mm, and the vertical distance between the center of the main tuyere 41 end face and the center of the auxiliary tuyere 42 end face is 700mm, and the length of the main tuyere 41 is 650mm , the width is 380mm, the auxiliary tuyere 42 has a length of 650mm and a width of 230mm, the airflow velocity of the main tuyere 41 is 35m / s, and the airflow velocity of the auxiliary tuyere 42 is 26m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com