Production system of rubber filler

A production system and filler technology, applied in refining to remove heteroatoms, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as damage to catalyst performance, reduction of catalyst service life, and inability of catalyst to be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

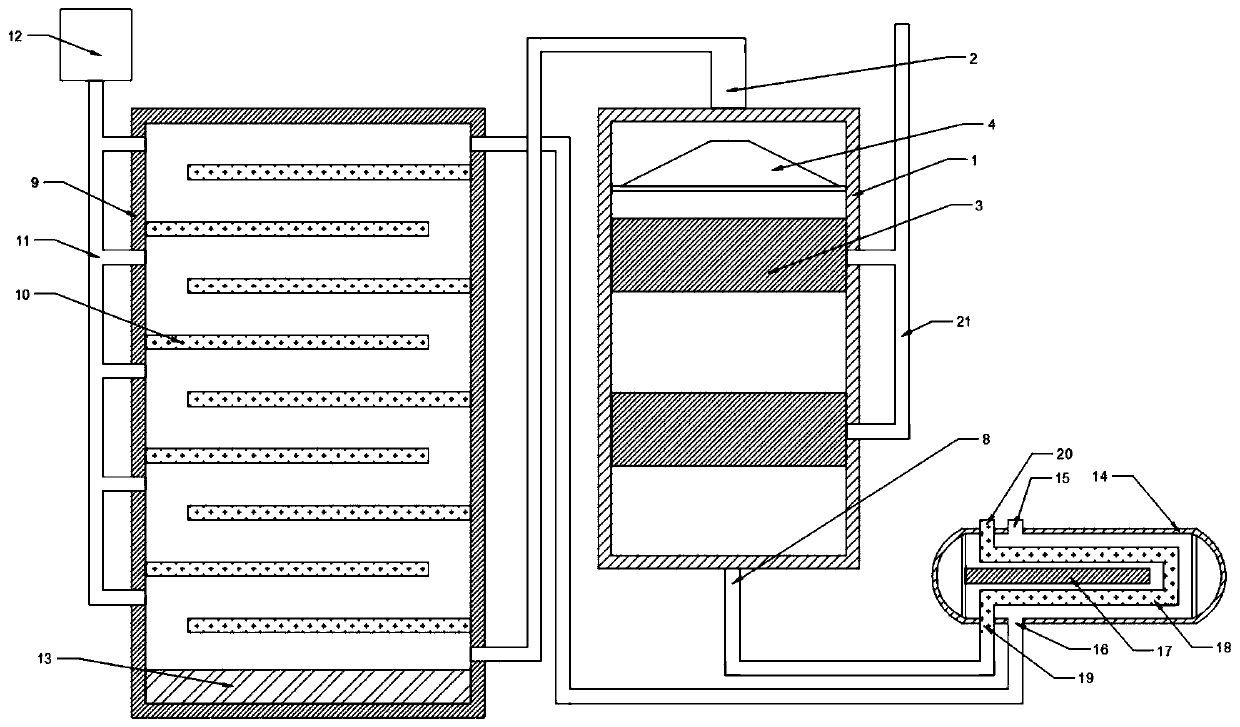

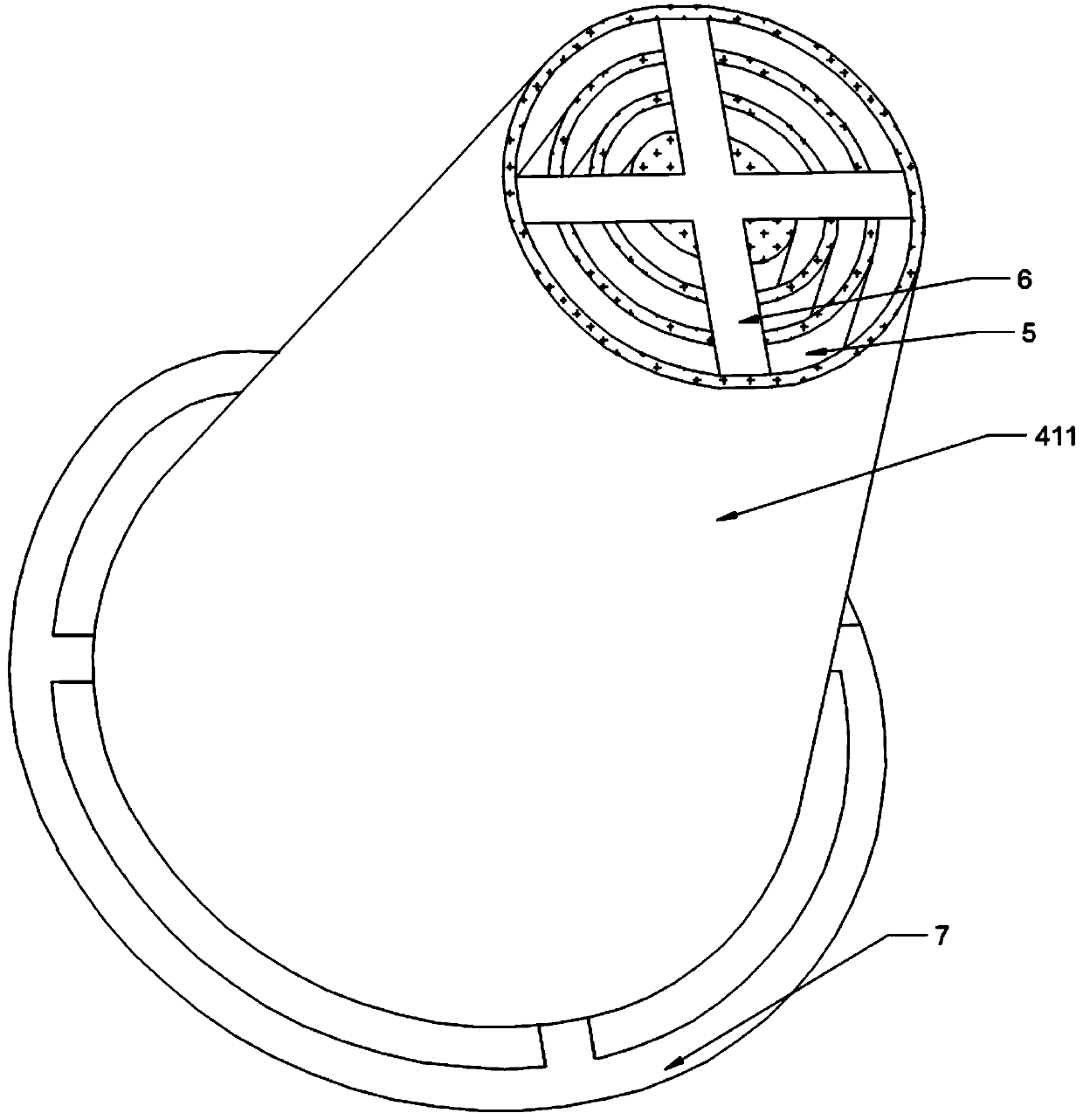

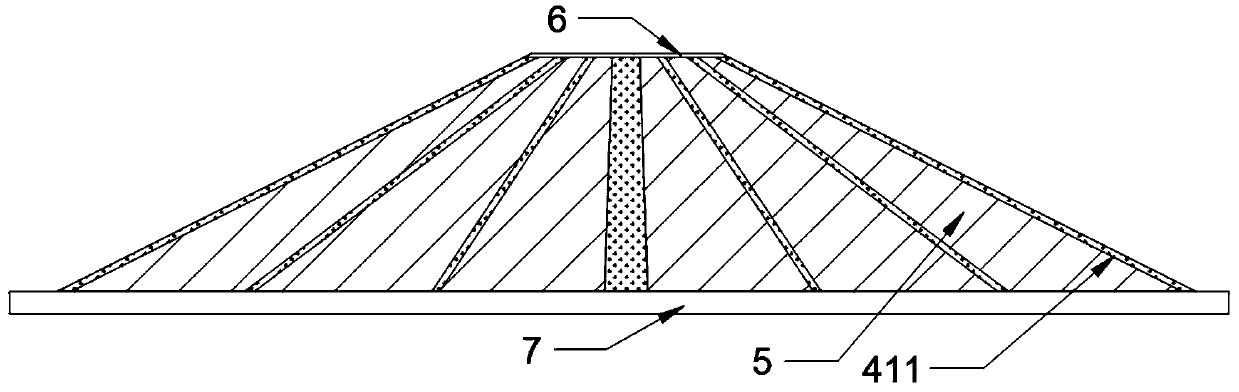

[0022] see Figure 1 to Figure 5 , the present invention provides a production system for rubber fillers, including a reaction tank 1, the top of the reaction tank 1 is provided with a feed pipe 2, crude oil and hydrogen are mixed and heated to reach the reaction temperature and then transported through the feed pipe 2 In the reaction tank 1, several catalyst beds 3 are sequentially arranged in the reaction tank 1 from top to bottom. After crude oil enters the reaction tank 1, it passes through each section of the catalyst bed 3, layer by layer. Carry out hydrogenation reaction, the top of described catalyst bed 3 is provided with diverter mechanism 4, and described diverter mechanism 4 is positioned at the bottom of described feed pipe 2, and described diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com