Rubber flap cover material and preparation method of rubber flap cover

A rubber and rubber-based technology is applied in the field of rubber flap cover materials and the preparation of the rubber flap cover. Good, easy to color, easy to disassemble and replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

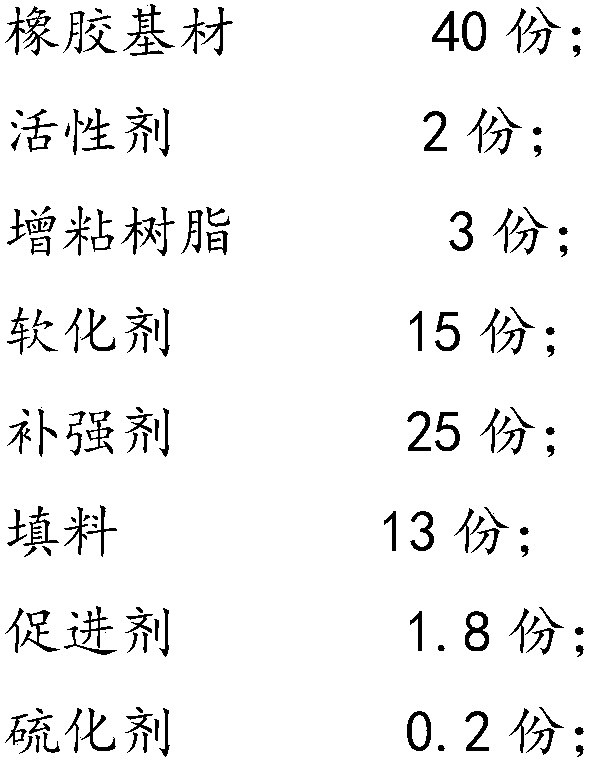

[0045] The rubber clapper cover material of the present embodiment comprises the following components in parts by weight:

[0046]

[0047] The above-mentioned rubber substrate adopts EPDM rubber; the active agent adopts zinc oxide and stearic acid; the tackifying resin adopts terpene resin; the softener adopts paraffin oil; the reinforcing agent adopts carbon black and white carbon black; 500-5000 mesh talcum powder is used as filler; dithiocarbamate is used as accelerator; sulfur is used as vulcanizing agent.

[0048] The formula of the rubber clapper cover of this embodiment (named Y3) is prepared by using the above-mentioned rubber clapper cover material through the following steps:

[0049] Step 1. Internal mixer mixing

[0050] After raising the temperature of the internal mixer to 50°C, put in EPDM, stir for 10 minutes to make the rubber base material soften and uniform, add the active agent, stir for 5 minutes to make the active agent disperse evenly in the rubber ...

Embodiment 2

[0071] The rubber clapper cover material of the present embodiment comprises the following components in parts by weight:

[0072]

[0073]

[0074] The above-mentioned rubber substrate is styrene-butadiene rubber; the active agent is zinc oxide; the softener is rubber softening oil; the reinforcing agent is carbon black and white carbon black; the filler is barium sulfate and talcum powder, and the particle size is 500-5000 mesh; The accelerator is used in combination with guanidine and thiazole; the vulcanizing agent is used in combination with sulfur carrier and sulfur.

[0075] The rubber clapper cover of this embodiment is prepared by using the above-mentioned rubber clapper cover material through the following steps:

[0076] Step 1. Internal mixer mixing

[0077] After raising the temperature of the internal mixer to 50°C, put in styrene-butadiene rubber, pressurize the top bolt, and stir for 8 minutes to soften the rubber base material evenly, then add the activ...

Embodiment 3

[0093] The rubber clapper cover material of the present embodiment comprises the following components in parts by weight:

[0094]

[0095] The above-mentioned rubber substrate adopts silica gel; the active agent adopts stearic acid; the tackifying resin adopts phenolic resin; the softener adopts naphthenic oil; The mesh size is 500-5000; the accelerator is used in combination with sulfenamides and thiurams; the vulcanizing agent is used in combination with sulfur carrier and sulfur.

[0096] The rubber clapper cover of this embodiment is prepared by using the above-mentioned rubber clapper cover material through the same steps as those in the embodiment, so details are not repeated here.

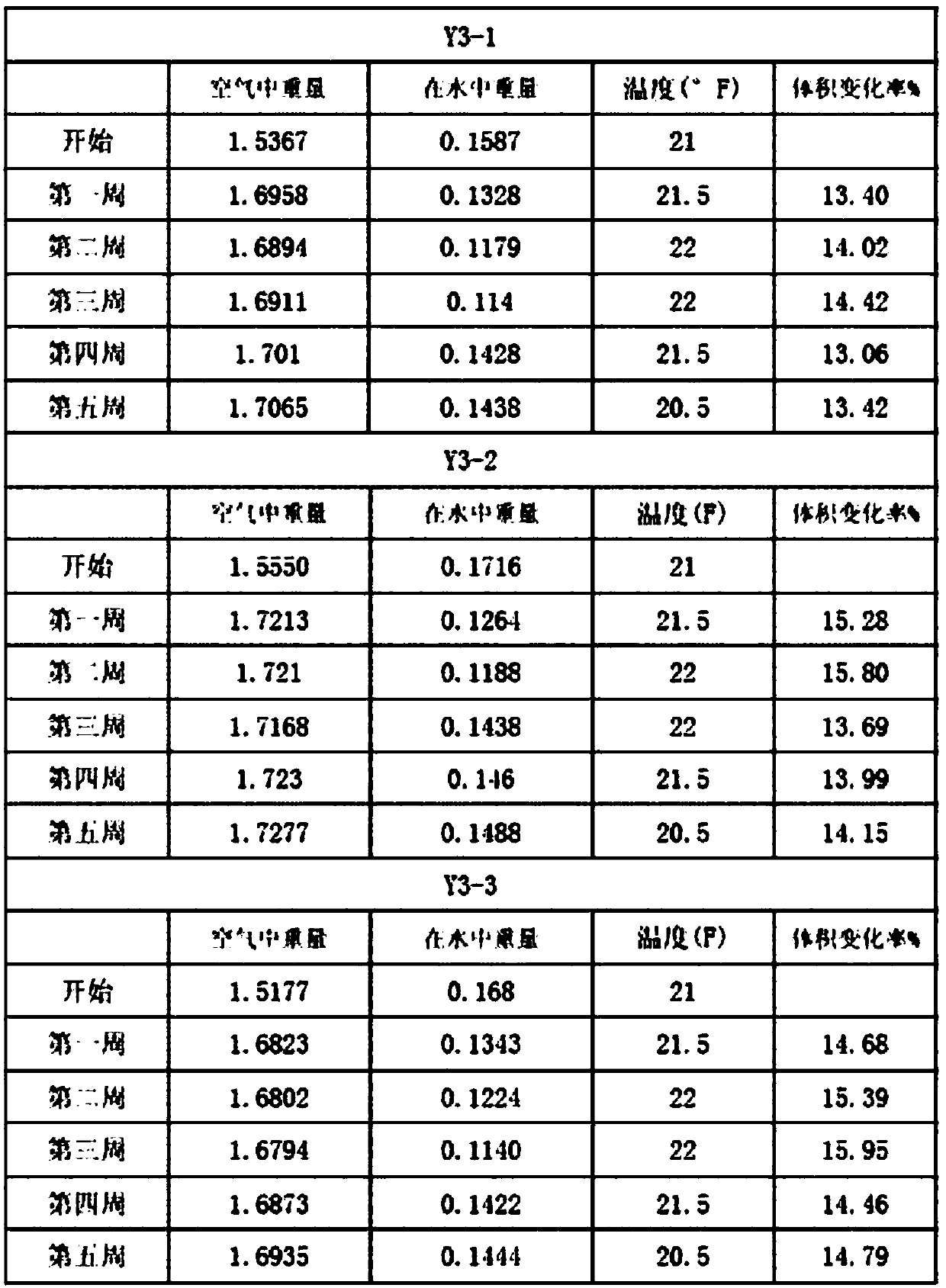

[0097] The rubber material prepared in Example 3 was tested by various performance indicators in Example 1, and the results confirmed that the rubber material in this example also has good resistance to chloramine solution, good sealing performance, and excellent mechanics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com