Automatic expanding feeder for radiating tube

A heat pipe and feeder technology, applied in heat exchange equipment, push-out equipment, etc., can solve the problems of high cost, unable to keep up with the production speed of fins, etc., and achieve the effect of automatic completion, reasonable layout design, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

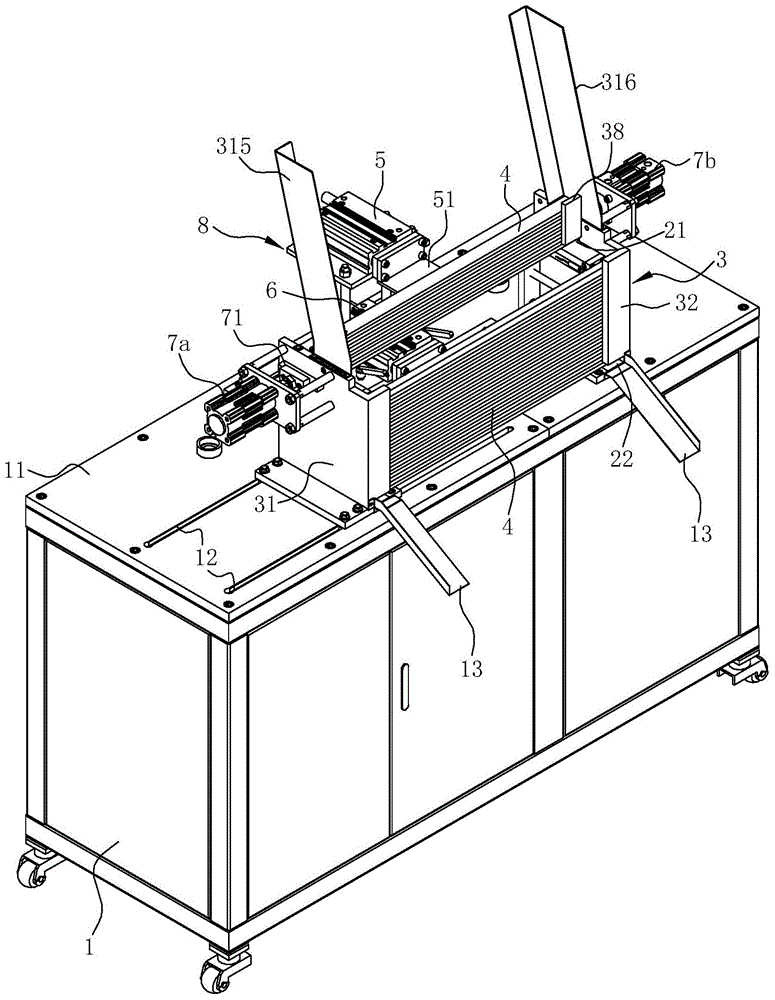

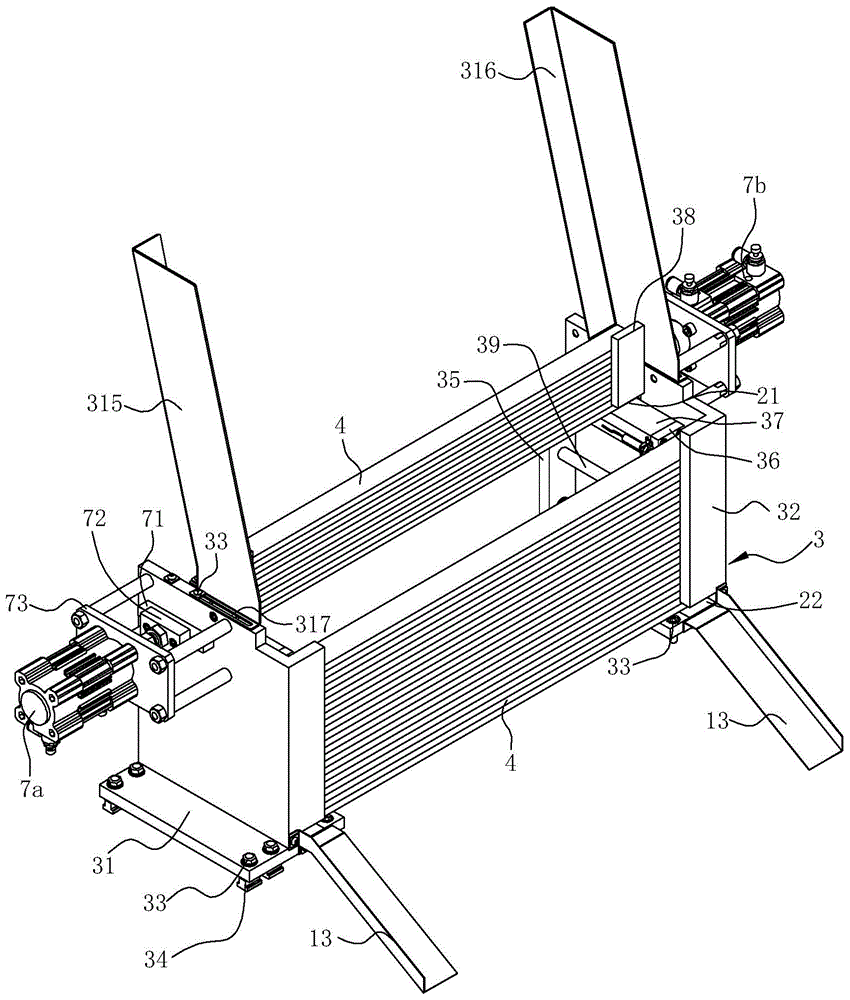

[0022] Such as Figure 1~4 Shown is a preferred embodiment of the present invention.

[0023] A cooling pipe automatic flare feeding machine, comprising a frame 1, the upper part of the frame 1 has a mounting platform 11, the bottom of the frame is provided with rollers, and the mounting platform 11 of the frame 1 is provided with a stacking part, a feeding part and an expanding part. mouth part.

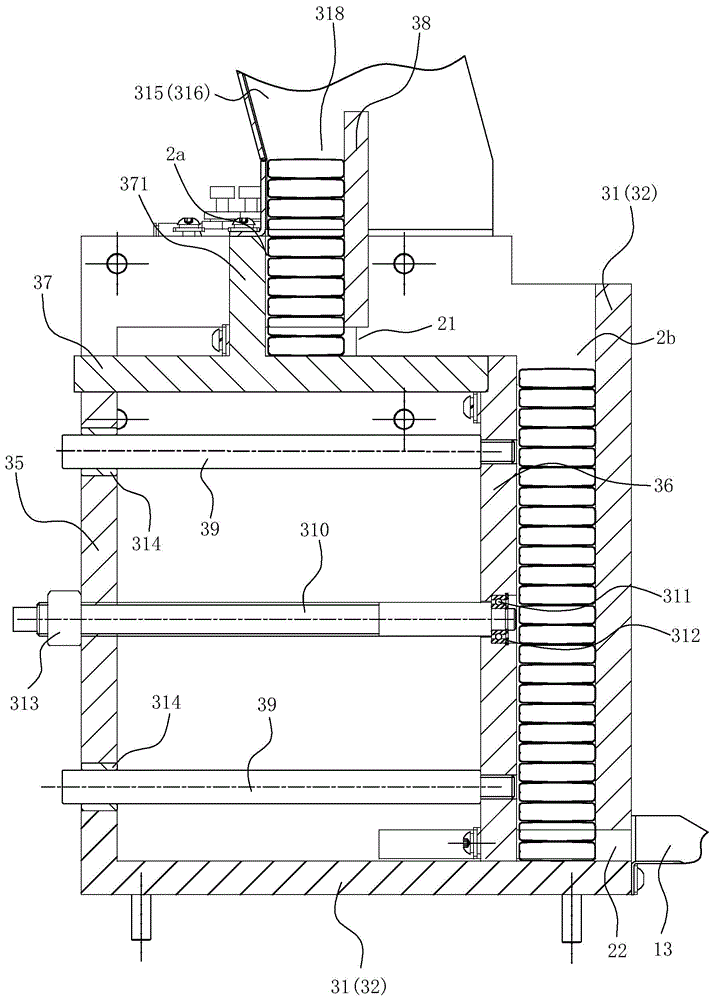

[0024] Such as figure 2 , 3 As shown, the stacking part includes a stacker 3, which has an upper stocking tank 2a vertically arranged for stacking heat pipes 4 to be flared, and vertically arranged for stacking the heat dissipation pipes 4 after flared. The lower storage tank 2b of the pipe 4, the lower storage tank 2b is located at the front and lower part of the upper storage tank 2a, a position sensor is installed on the top of the lower sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com