Multifunctional CNC spring forming machine

A forming machine and multi-functional technology, which is applied in the direction of manufacturing springs from wires, other household appliances, household appliances, etc., can solve the problems of inaccurate wire feeding position, insufficient clamping force of metal wire, and great influence on the production efficiency of spring machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

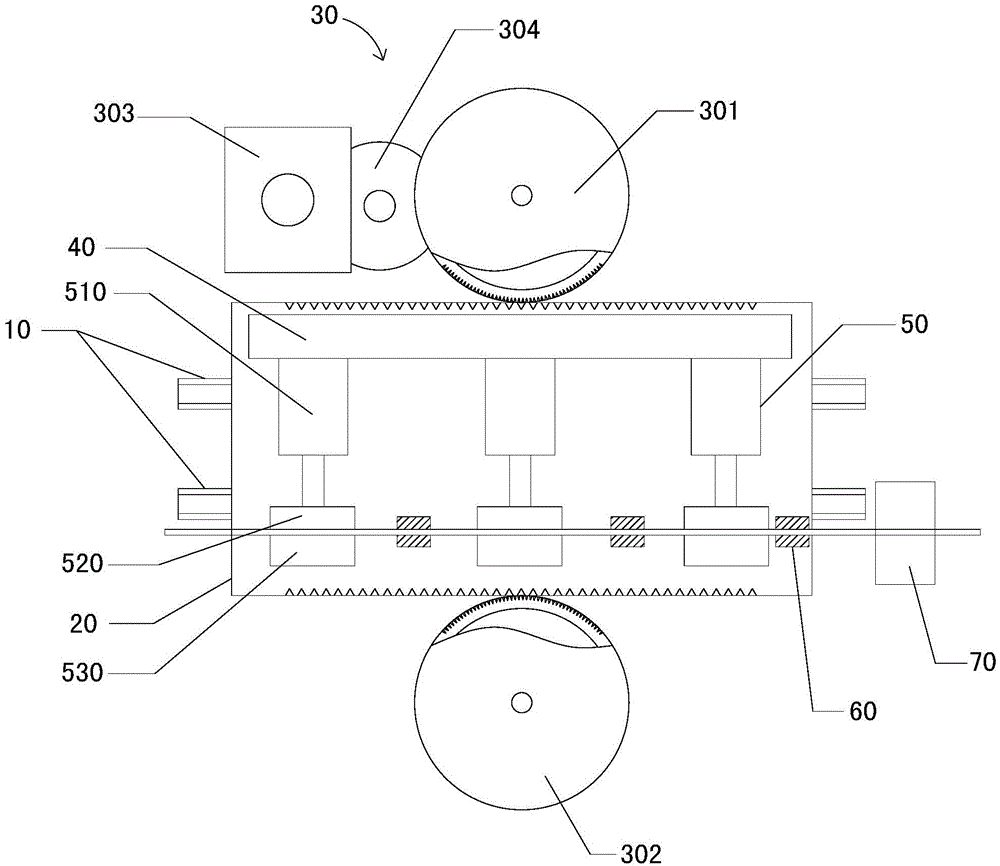

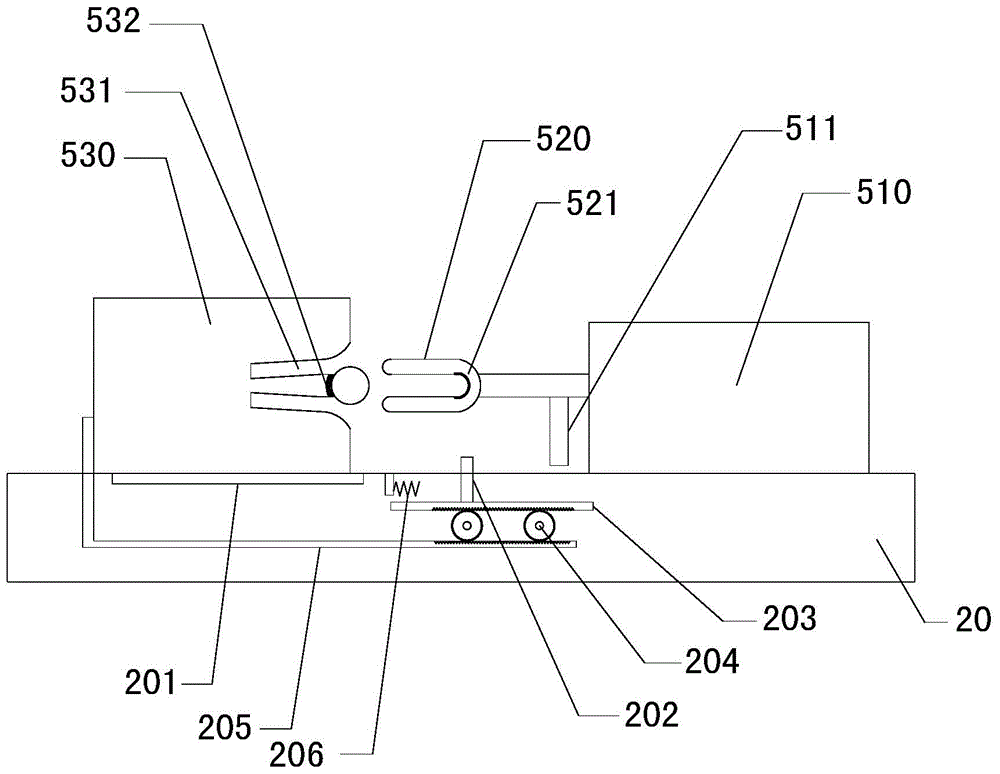

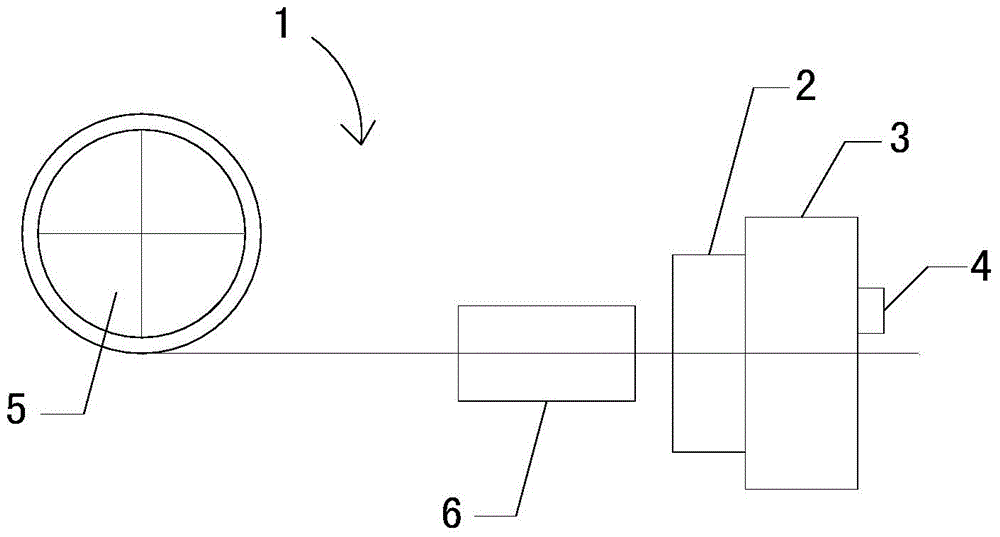

[0019] see Figure 1 to Figure 3 , a multi-functional computer spring forming machine according to a preferred embodiment of the present invention includes a wire feeding and turning transmission mechanism 1, a straightening mechanism 2, a crimping forming mechanism 3 and a cutting mechanism 4, and the wire feeding and turning transmission mechanism 1 includes winding The wire reel 5 and the wire feeding device 6, the metal wire passes through the wire feeding and turning transmission mechanism 1, the straightening mechanism 2, the crimp forming mechanism 3 and the cutting mechanism 4 in turn, and finally is formed in the crimp forming mechanism and is cut by the cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com