Sawing machine

A technology of sawing machine and frame, which is applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc. It can solve the problems of uneven cutting quality, easy improper operation, personal safety, and low cutting efficiency, and achieve high precision High efficiency, beautiful layout and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

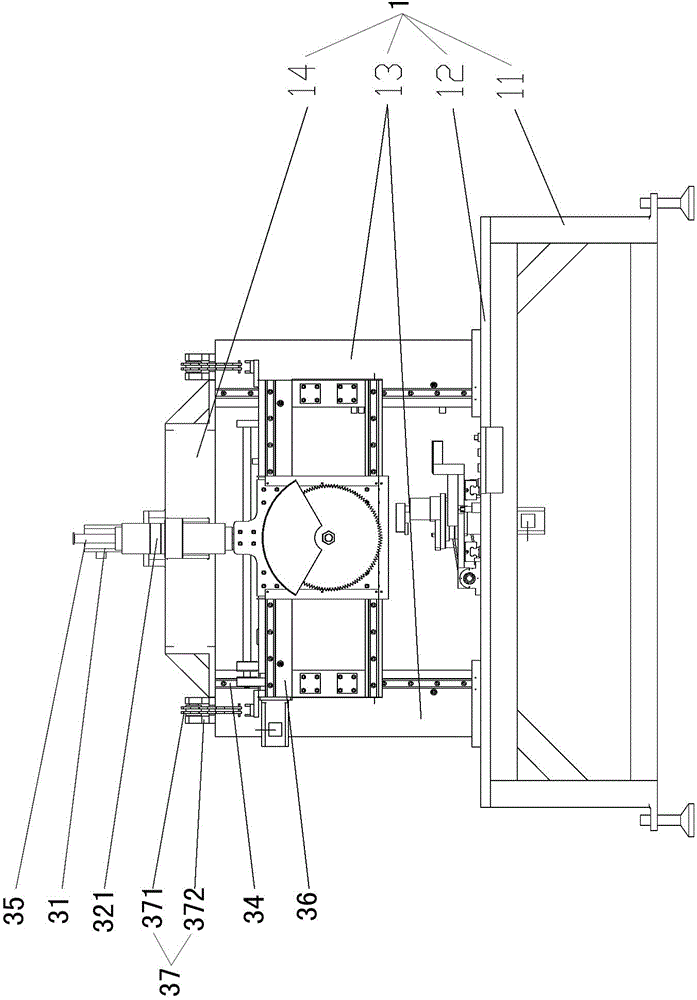

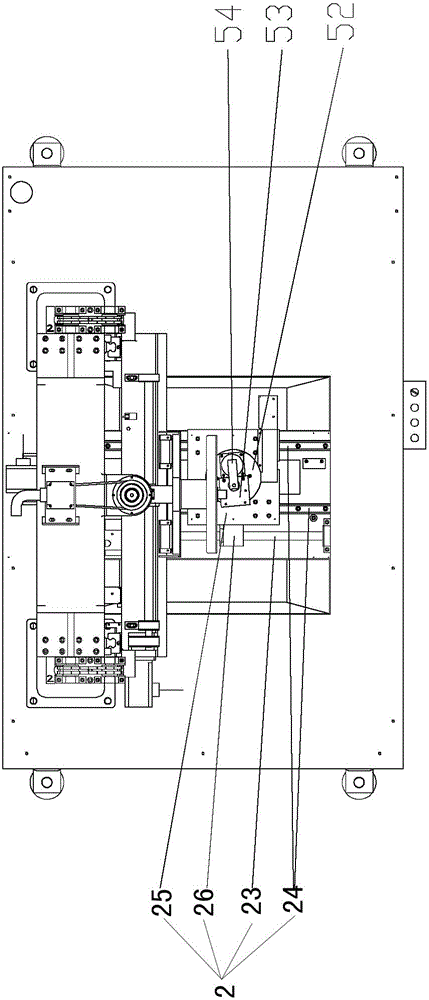

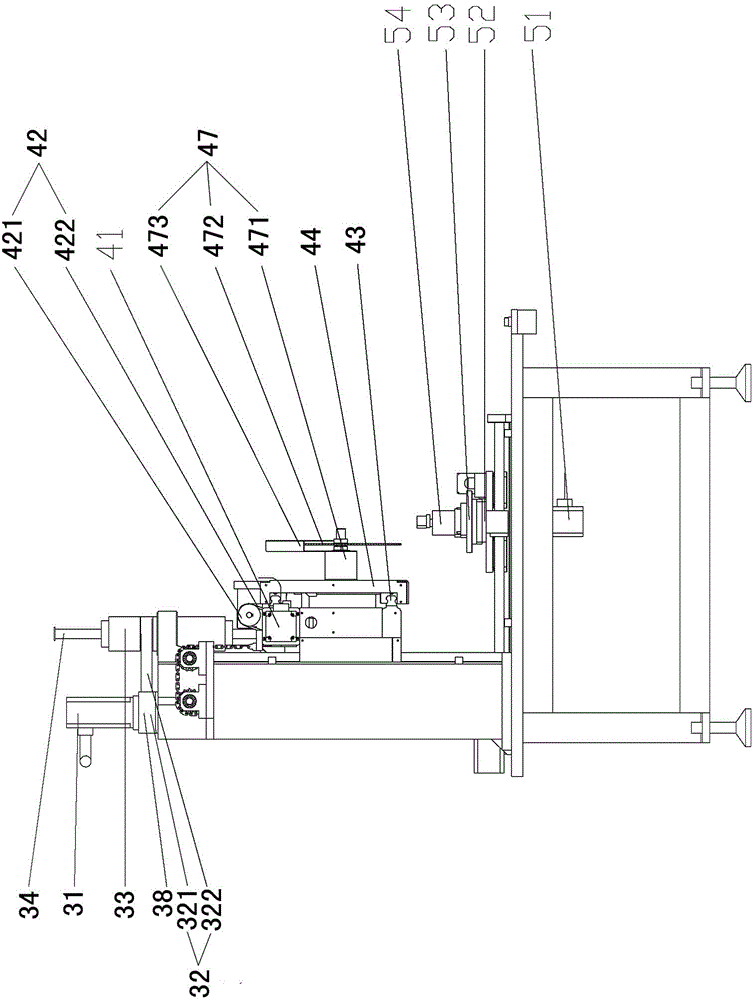

[0030] Such as Figure 1-Figure 5 Shown embodiment of the present invention, described sawing machine comprises:

[0031] Frame 1 comprises: machine base 11; Mounting plate 12: be installed on the machine base 11; Support 13: be installed on the mounting plate 12; Beam 14: be installed on the support 13.

[0032] The X-axis mechanism 2 includes: a motor mounting base 27: installed on the base mounting plate 12; an X-axis motor 22: installed on the motor mounting base 27, the X-axis motor is controlled by a control system, and its output shaft extends laterally for motor installation Seat 27; X-axis synchronous pulley 221: installed on the output shaft of X-axis motor 22; X-axis synchronous belt 222: installed on the X-axis synchronous pulley 221, meshed with the synchronous pulley; X-axis screw mandrel 23: with X Axis synchronous pulley 221 cooperates; X-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com