Tool bit lifting and clamping device and control strategy of diamond tool welding machine

A diamond tool and clamping device technology, which is applied in the field of control strategy of cutter head lifting clamping device, diamond tool welding machine, cutter head lifting clamping device, and achieves the effects of improved control strategy, low damage rate and high welding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

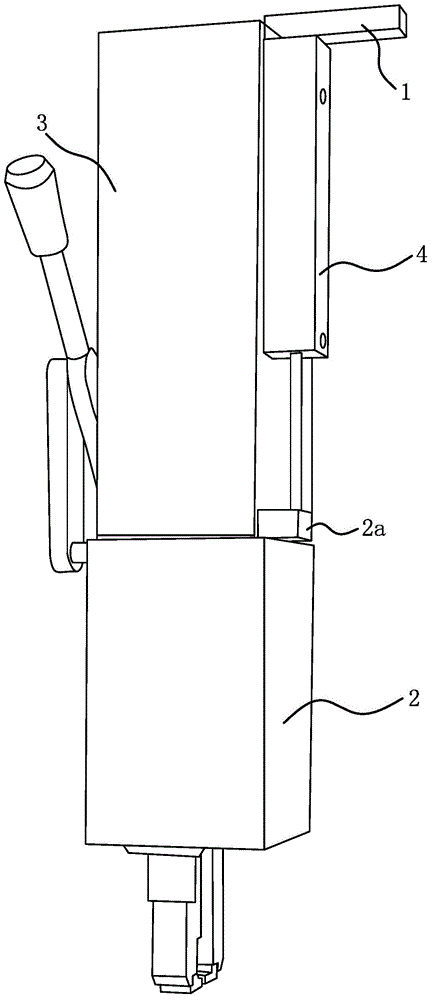

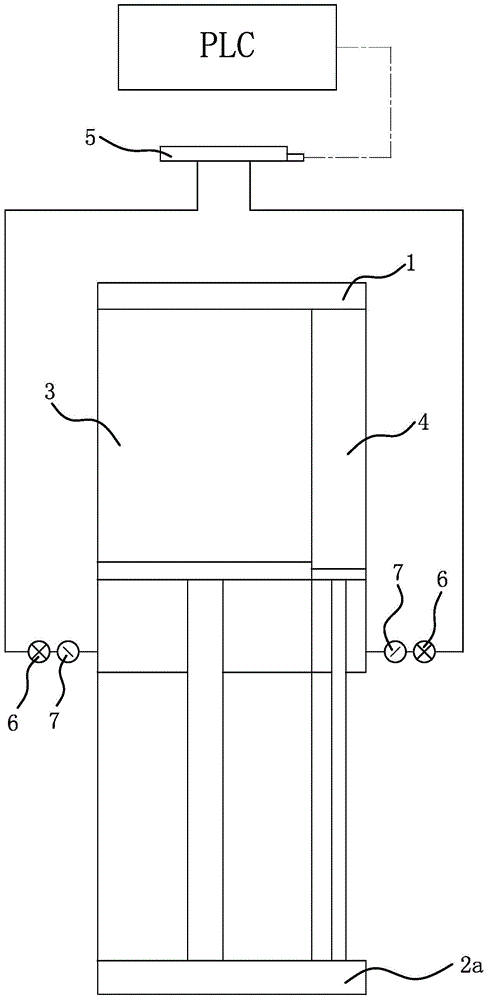

[0024] Such as figure 1 and figure 2 As shown, the diamond tool welding machine includes a frame, a cutter head lifting and clamping device and a PLC. The cutter head lifting and clamping device of the diamond tool welding machine includes a lifting seat 1, a clamping assembly 2, a lifting cylinder 3 and a lifting cylinder 4.

[0025] The lifting base 1 is a base part, and the lifting base 1 is connected with the frame through guide rails. The lifting cylinder 3 is a pneumatic carriage, and the cylinder body of the lifting cylinder 3 is fixedly connected with the lifting seat 1. The clamping assembly 2 has a clamping seat 2a, and the clamping seat 2a is fixedly connected with the carriage of the lifting cylinder 3 .

[0026] The lifting cylinder 4 and the lifting cylinder 3 are arranged side by side, the cylinder body of the lifting cylinder 4 is fixedly connected with the lifting seat 1, and the piston rod of the lifting cylinder 4 is fixedly connected with the clamping s...

Embodiment 2

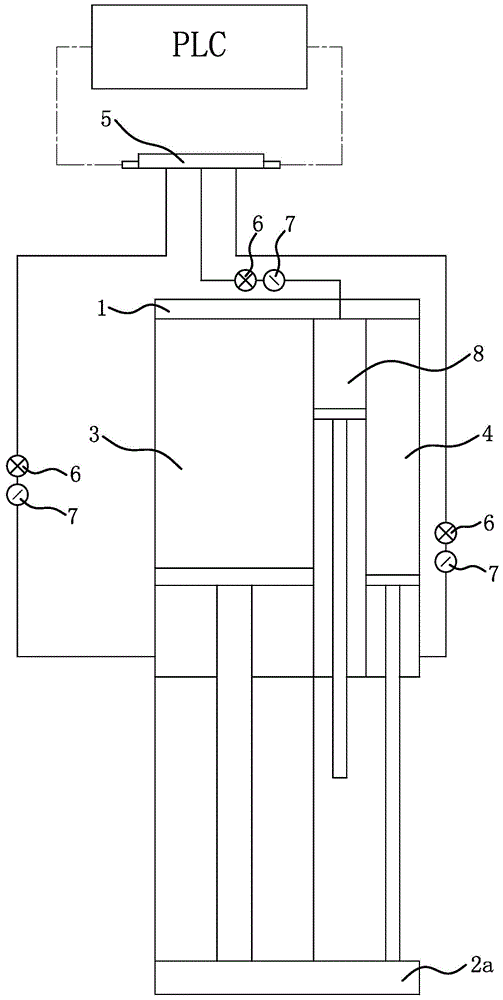

[0030] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: image 3 Shown, this cutter head elevating clamping device also comprises downward pressure cylinder 8, and downward pressure cylinder 8 is arranged side by side with lifting cylinder 3, and the cylinder block of downward pressure cylinder 8 is fixedly connected with lifting seat 1, and the piston rod of downward pressure cylinder 8 is connected with The clamping seat 2a is oppositely arranged, that is, the piston rod can abut against the clamping seat 2a after being stretched out, thereby pushing the clamping seat 2a to move.

[0031] The inner cavity diameter of the lower pressure cylinder 8 is smaller than the inner cavity diameter of the lifting cylinder 3, such as the inner cavity diameter of the lifting cylinder 4 is 100mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com