Novel mechanical arm based on double-bevel deflection joints

A dual-slope, robotic arm technology, applied in the field of robotic arms, can solve the problems of less attention to the basic structure, frequent start-stop and commutation of the motor, and the inability to maintain the high-speed characteristics of the motor in an ideal state, so as to improve power density and fast action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The preferred embodiment of the novel mechanical arm based on the double-slope deflection joint of the present invention is:

[0024] including at least one double-slope deflection joint, the end of the mechanical arm is equipped with a mechanical gripper;

[0025] The double-slope deflection joint includes a proximal mounting base, a proximal motor, a proximal driving gear, a proximal internal gear, a proximal swash plate, a universal joint, a distal swash plate, a distal internal gear, a distal Drive gear, remote motor, remote mount;

[0026] The proximal motor is installed on the proximal mounting base, the proximal driving gear is mounted on the output shaft of the proximal motor and meshes with the proximal internal gear, and the proximal internal gear and the proximal rotary bevel Disk connection, the proximal swash plate is installed on the proximal mounting base through a proximal bearing, and connected with the distal swash plate through a slant bearing;

[0...

specific Embodiment

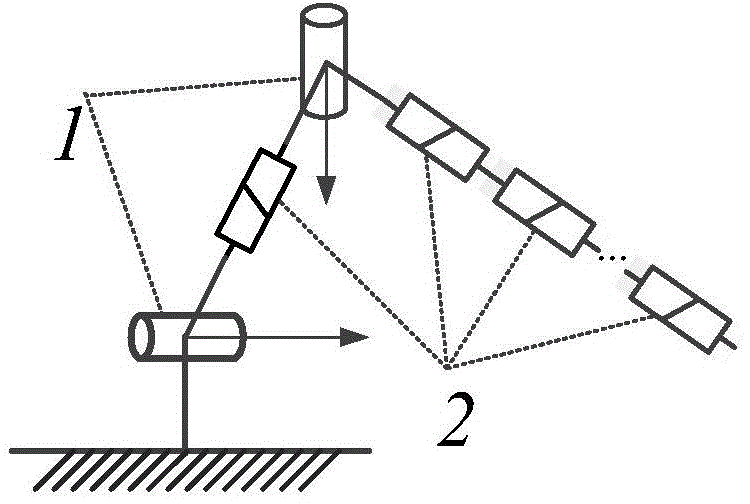

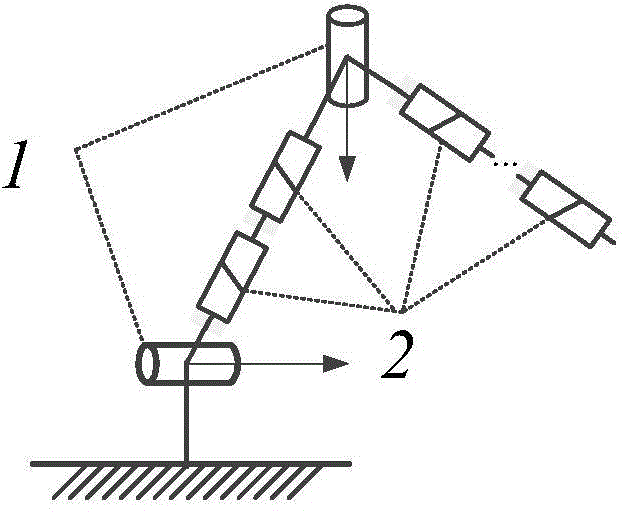

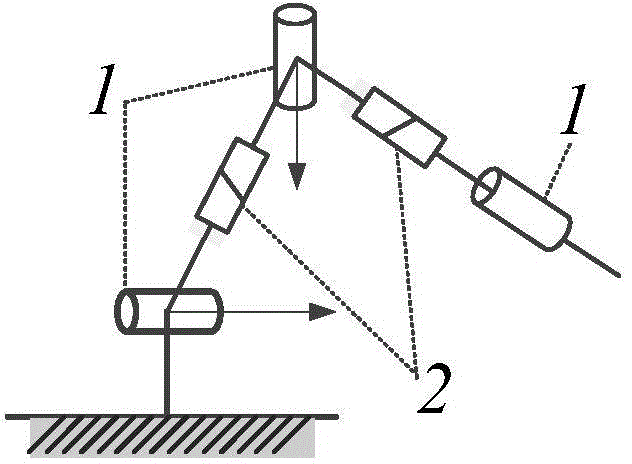

[0045] As shown in Figure 1, the mechanical arm of the present invention is composed of a single-degree-of-freedom rotary joint (1) and a double-slope deflection joint (2) installed in series in a certain order; the single-degree-of-freedom rotary joint uses a motor to directly drive the joint to rotate, which can Realize a wide range of working space; the double-slope deflection joint adopts two motors to drive the double-slope coupling movement, which can realize the fast double-degree-of-freedom movement of the joint.

[0046] Fig. 2 shows the implementation of the double-slope deflection joint, which consists of two symmetrically arranged drive parts, which are connected and axially restrained by universal joints; the proximal motor (3) is fixed on the proximal mounting base (5), and the proximal The end driving gear (4) is fixed on the output shaft of the proximal motor (3), forms a gear engagement relationship with the proximal internal gear (7), and then rotates the prox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com