Roll-to-roll based UV cured polymer film surface microstructure processing system and method

A technology of polymer film and processing system, which is applied in the field of surface microstructure processing system based on roll-to-roll UV curing polymer film, can solve the problems of single-sided optical structure processing, avoid secondary imprinting, save time, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

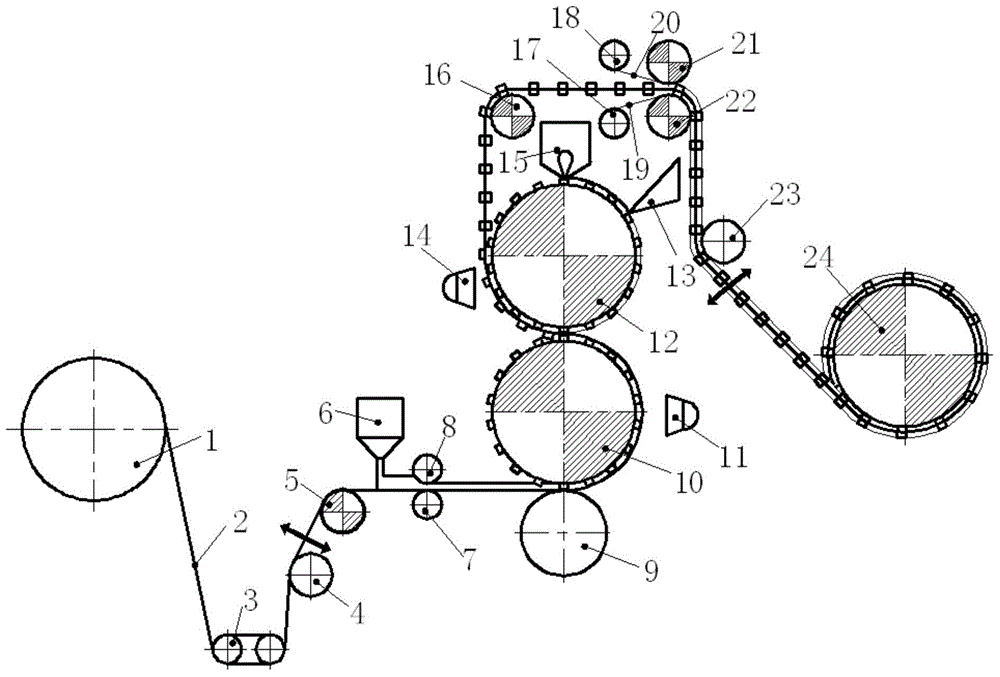

[0041] A surface microstructure processing device based on roll-to-roll UV curing polymer film, its structure is as follows figure 1 As shown, it includes a set of forward imprinting equipment and a set of reverse imprinting equipment. The forward imprinting equipment includes an unwinding device, a coating device, a rolling device, a UV curing device, a protective film sticking device, and a winding device arranged in sequence. Device; Reverse embossing equipment and forward imprinting equipment share unwinding device and rewinding device, in addition, it also includes independent coating device, rolling device, UV curing device.

[0042] The unwinding device includes an unwinding roller 1, a deviation correction device 3, a tension control device 4, and a driving roller 5; the tension control device 4 is provided with a tension sensing device, and the control system is connected to the tension control device 4 to sense the film to be embossed and the embossed film When the t...

Embodiment 2

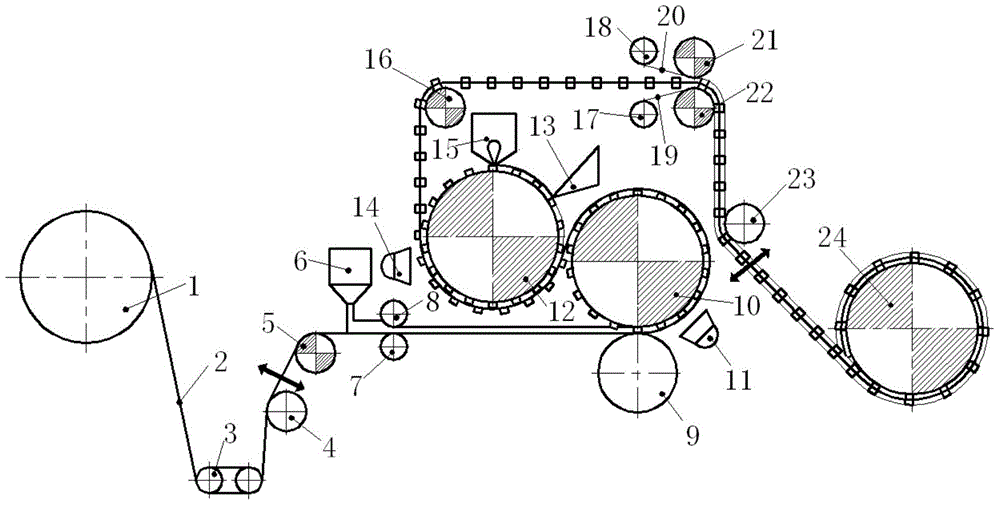

[0059] Such as figure 2 As shown, based on the implementation case 1, the reverse imprinting equipment is moved to the lower left as a whole to ensure that there is a larger wrap angle between the substrate 2 and the reverse mold roll 12, and increase the transfer contact time and shape retention time, thereby ensuring a better Good reverse transfer effect.

[0060] The size of the microstructure pattern on the forward-cured surface is 30 μm, the size of the microstructure pattern on the reverse-cured surface is 5 μm, the thickness of the substrate film is 80 μm, and its material is polyester (PET, Polyester).

[0061] The advantage of this case is: due to the downward movement of the reverse rolling device, there is a longer contact distance and a larger shape retention angle between the reverse mold roller and the substrate, which increases the shape retention time and better guarantees Molding quality of reverse transfer printing.

Embodiment 3

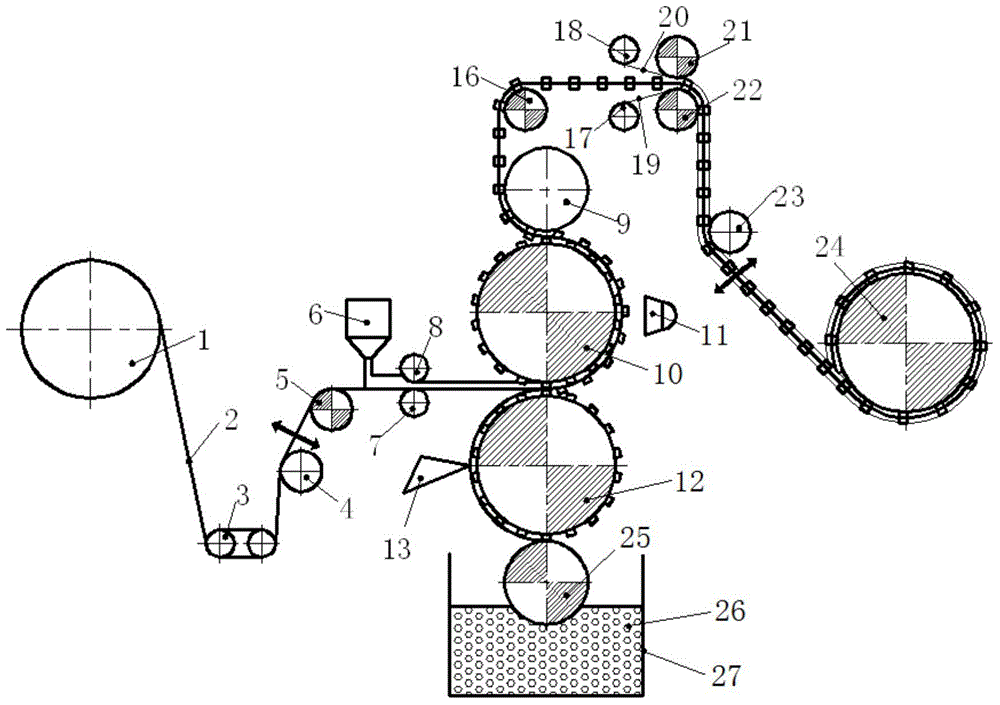

[0063] A surface microstructure processing device based on roll-to-roll UV curing polymer film, such as image 3 As shown, it includes a set of forward imprinting equipment and a set of reverse imprinting equipment. The forward imprinting equipment includes an unwinding device, a coating device, a rolling device, a UV curing device, a protective film sticking device, and a winding device arranged in sequence. Device; Reverse embossing equipment and forward imprinting equipment share unwinding device and rewinding device, in addition, it also includes independent coating device, rolling device, UV curing device. The unwinding device, the protective film sticking device and the rewinding device are all the same as the implementation case 1.

[0064] The forward ultraviolet curing device is similar to the embodiment 1, except that the rubber roller 9 is placed on the top of the mold roller 10, while the rubber roller 9 is placed below the mold roller 10 in the embodiment 1;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com