Die supporting block mistake proofing device for press machine and press machine

A technology of support blocks and presses, applied in the directions of presses, manufacturing tools, etc., can solve problems such as hidden safety hazards of support blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

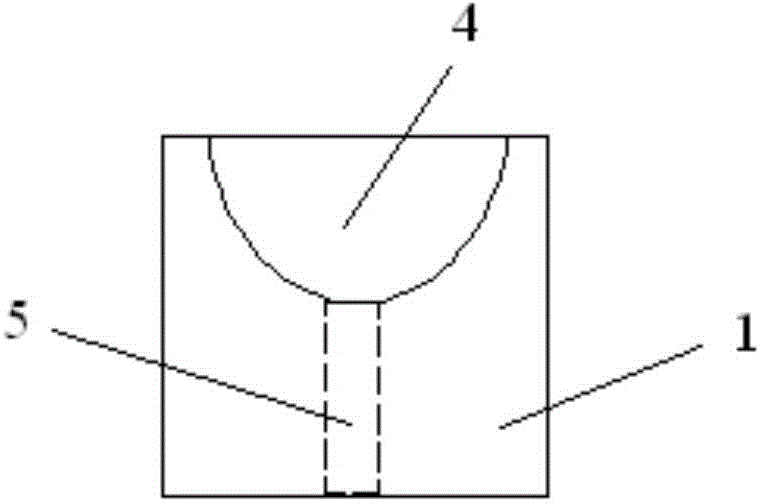

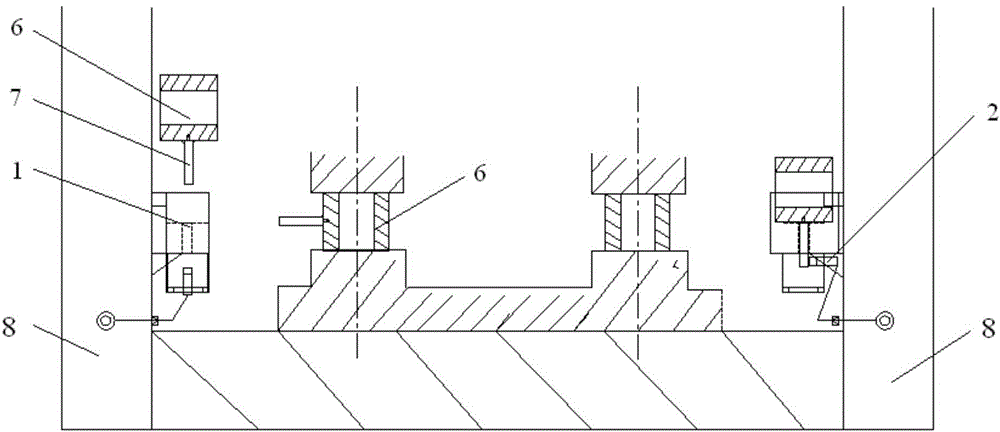

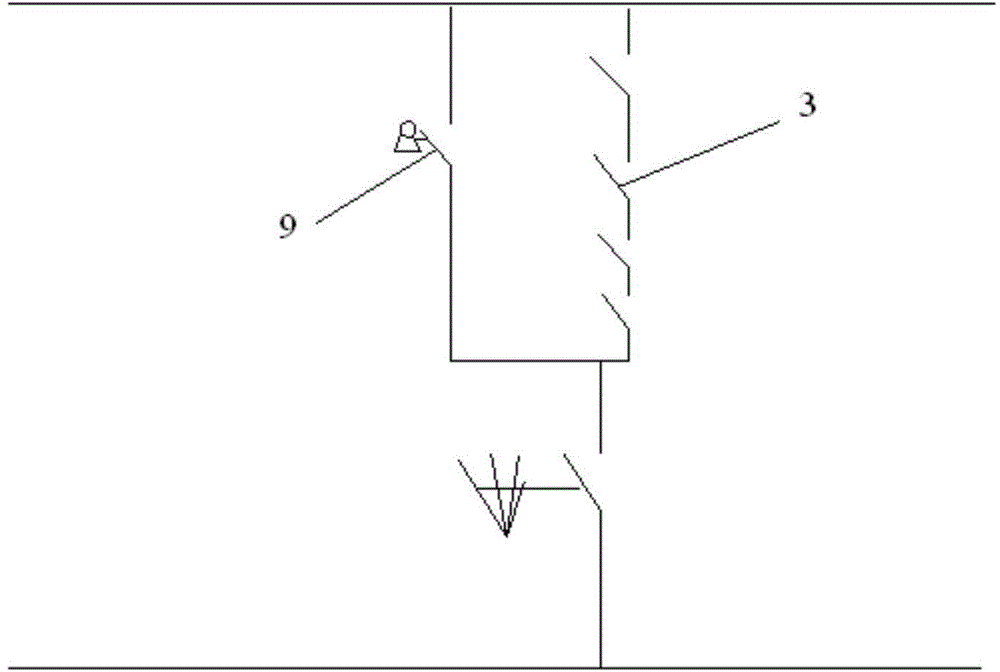

[0028] Such as Figure 1-3 As shown, the present invention provides a mold support block error prevention device for presses, including a storage bracket 1, a position sensor 2 and a normally open electronic switch 3, and the storage bracket 1 is provided with a storage part for storing the support block 6 , the position sensor 2 is used to detect whether the support block 6 is stored in the storage part and output an electrical signal; the normally open electronic switch 3 is connected in series in the power circuit of the press, and the normally open electronic switch 3 receives the electrical signal output by the position sensor.

[0029] Specifically, a press refers to a processing machine that applies pressure to a metal blank to cause plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com