Folding drawing board with drying and air-drying functions and working method of folding drawing board

A folding, drawing board technology, applied in painting tools, decorative arts, etc., can solve the problems of inconvenience to carry and transport, waste of examination time, large area, etc., to achieve the effect of easy carrying and transportation, and reducing the occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

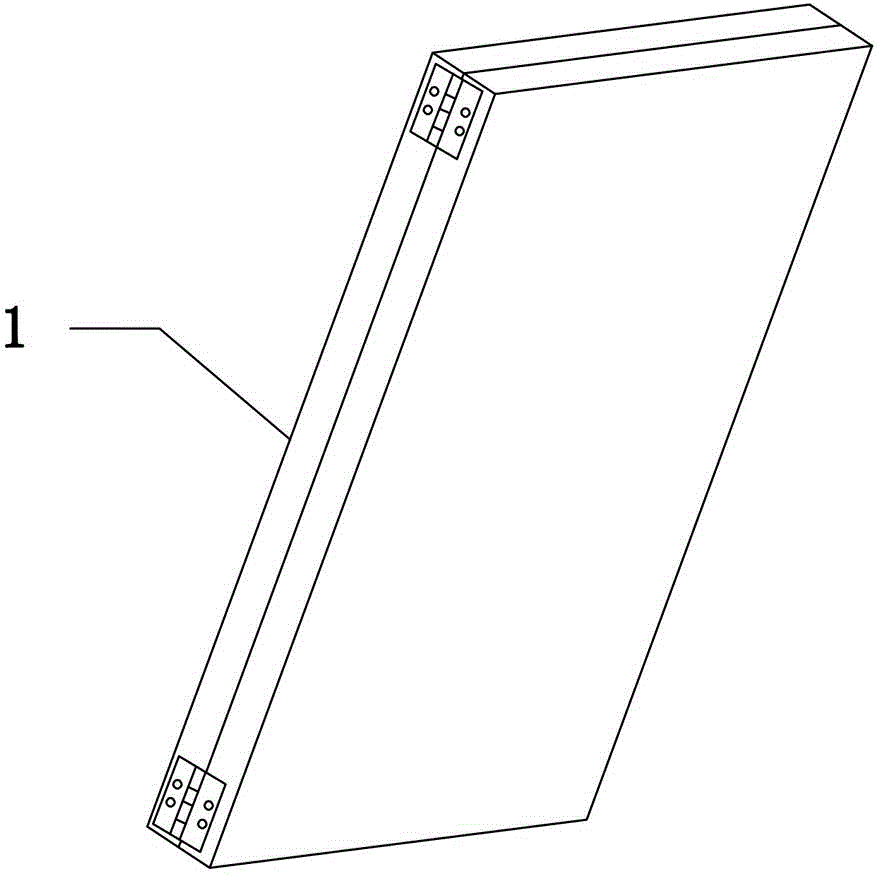

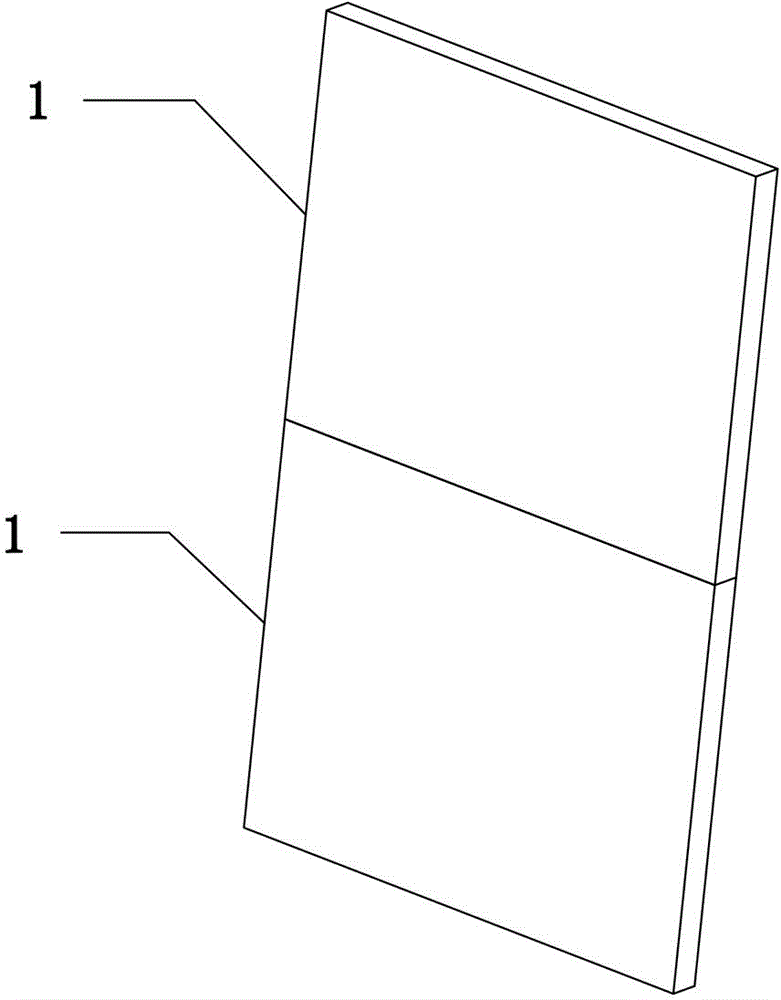

[0017] like Figure 1-2 As shown, in this embodiment, the drawing board body is composed of two drawing board blocks 1 of the same specification through two hinges. Its structure enables the two drawing board blocks 1 to be folded mutually, and the area of the folded drawing board body is reduced by half, making it easy to carry and transport.

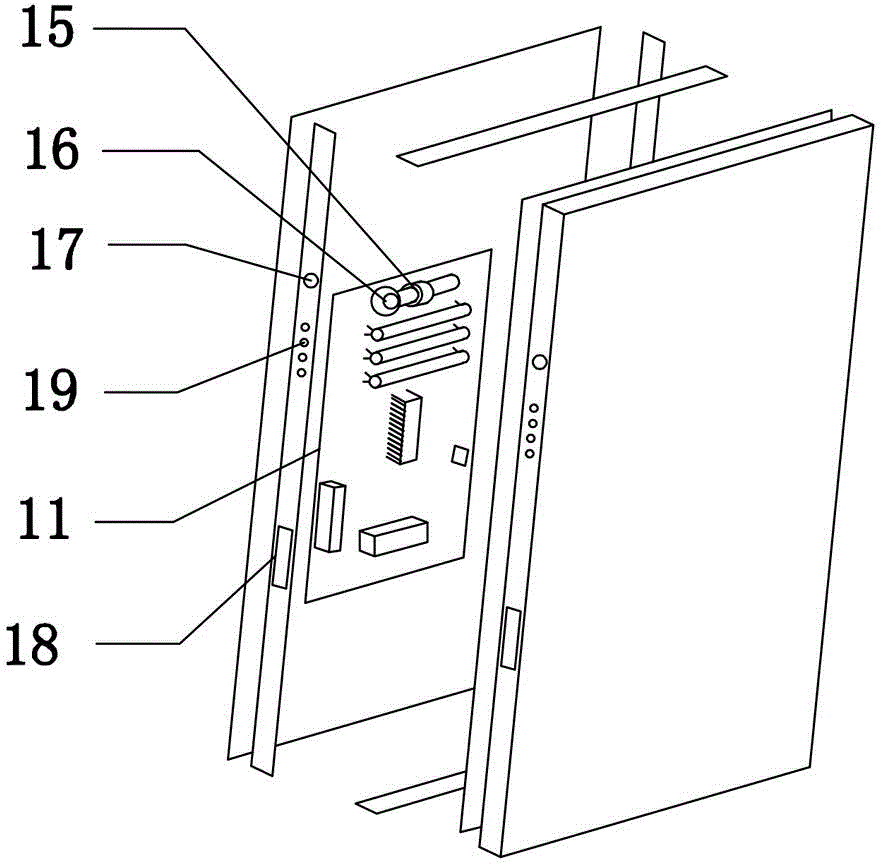

[0018] like image 3 As shown, in this embodiment, each drawing board block 1 is built with a heating resistance wire 12, a control board 11, a relay 13, a temperature sensor 14, a vacuum generator 15, a sucker 16 and a nixie tube 18; Function buttons 19 and suction cup placement holes 17 are provided on the outer surface of the side part; insulating and heat-conducting silicone sheets are attached to the six inner walls of the drawing board block 1 to protect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com