Novel electrolytic water equipment with bore-log-structured electrodes

A technology for electrolysis of water and electrodes, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as low electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

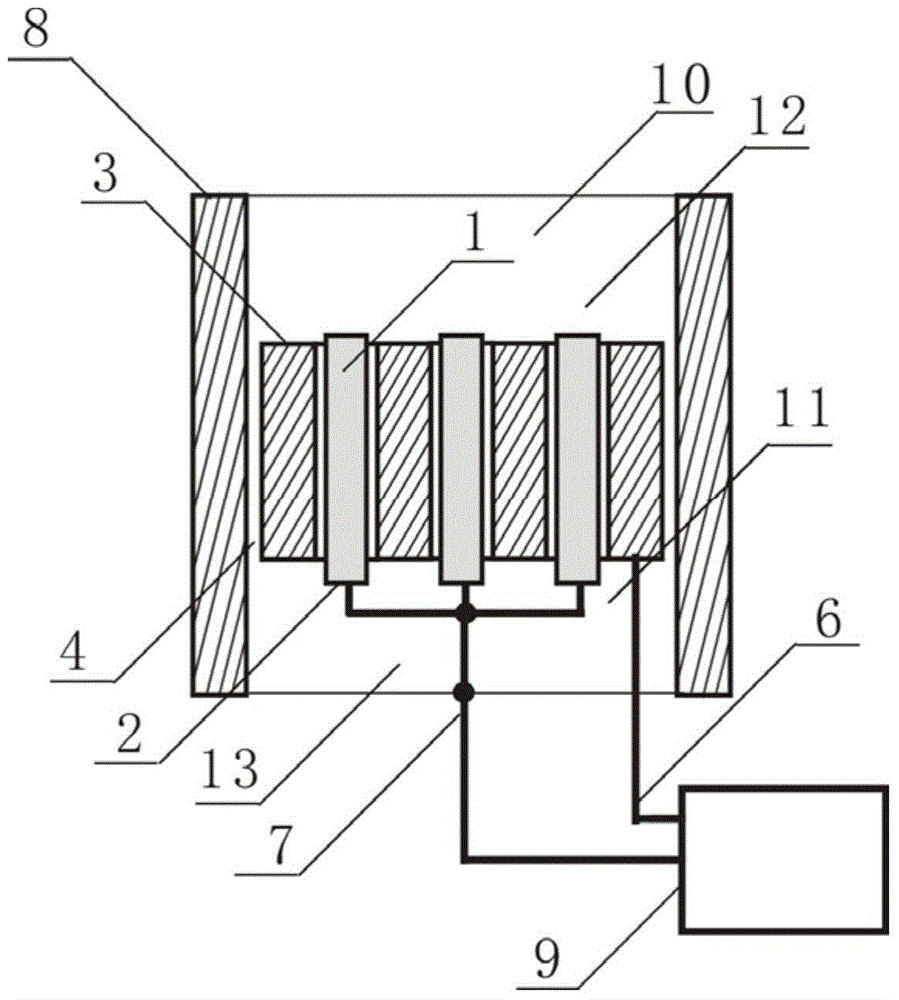

[0041] Such as figure 1 Shown is a new type of water electrolysis device in the present invention with electrodes in a hole-pillar structure, which is an embodiment applied to the electrolysis of flowing water driven by external force. 10 is the electrolytic cell, 8 is the wall of the electrolytic cell, and 13 is one of the entrances and exits of the electrolytic cell. The electrolytic electrode assembly is composed of two electrodes 1 and 2 with different polarities. , 1 and 2 can be plugged correspondingly, the column of the columnar electrode 2 is inserted into the corresponding hole of the hole electrode, and an electrolytic gap 3 is left between the surface of the column and the surface of the hole, and the gap is tubular. figure 1 The gap 3 composed of three columnar electrodes and hole-shaped electrodes is schematically drawn in , and the gap spacing can be selected within a certain range according to the needs, such as the range from less than 5mm to greater than 0mm; ...

Embodiment 2

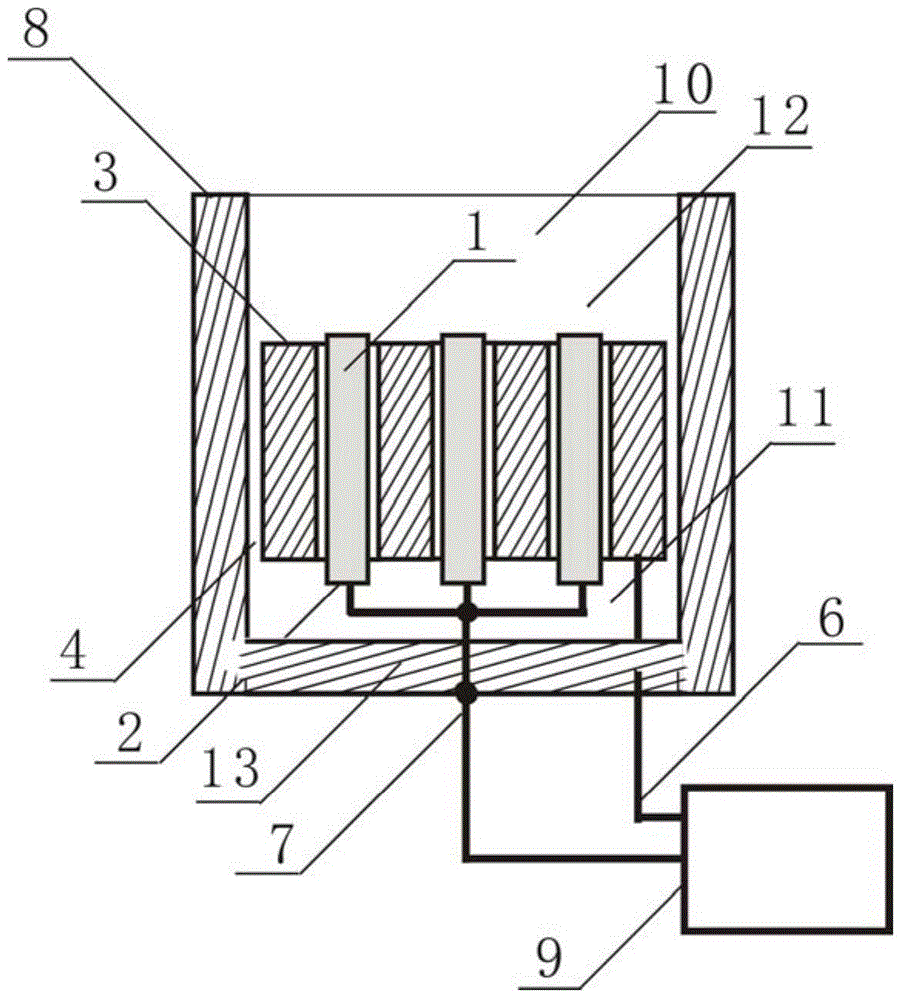

[0048] Such as figure 2 As shown, when a novel water electrolysis device in which the electrode is a hole column structure of the present invention belongs to the case of natural still water applied in an electrolysis container, the basic structure and working principle of this embodiment are similar to those of Embodiment 1, and 10 is electrolysis Tank, 8 is the wall of the electrolytic tank, and the electrolytic electrode assembly is composed of two electrodes 1 and 2 with different polarities. The electrode 1 is in the shape of a hole, and the electrode 2 is in the shape of a column. In the corresponding hole of the electrode, there is an electrolytic gap 3 between the surface of the column and the surface of the hole, and the gap is tubular. figure 1The gap 3 composed of three columnar electrodes and hole-shaped electrodes is schematically drawn in , and the gap spacing can be selected within a certain range according to the needs, such as the range from less than 5mm to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com