Device for repairing quartz crucible with laser

A quartz crucible and laser repair technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as affecting the quality of silicon rods, crystal structure dislocation, and reducing the yield of single crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

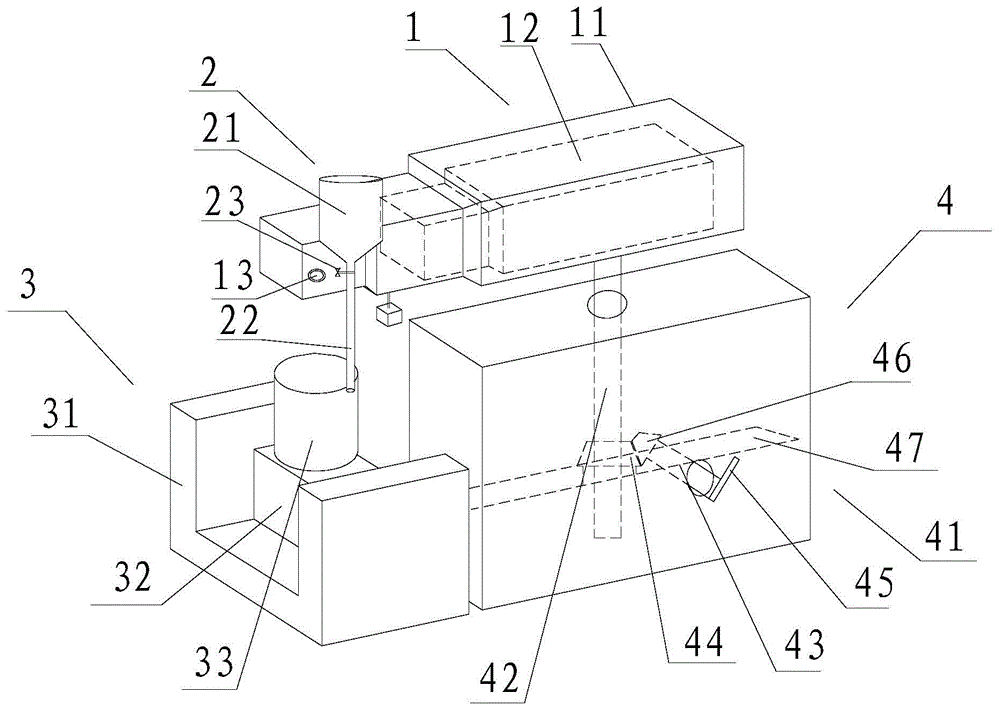

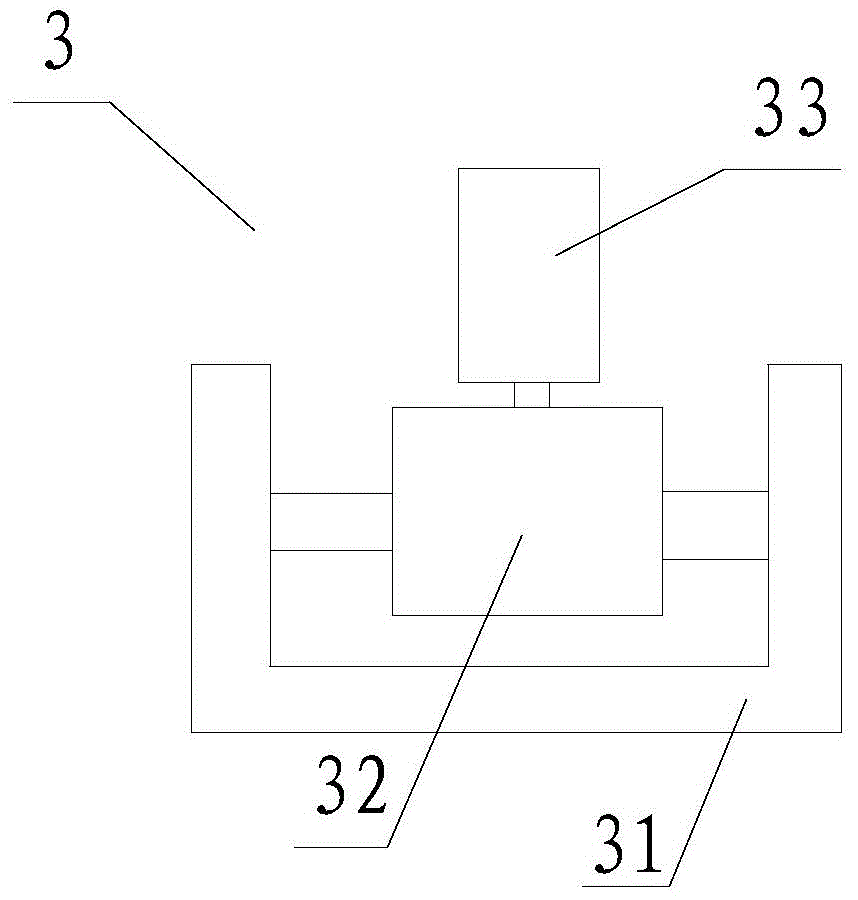

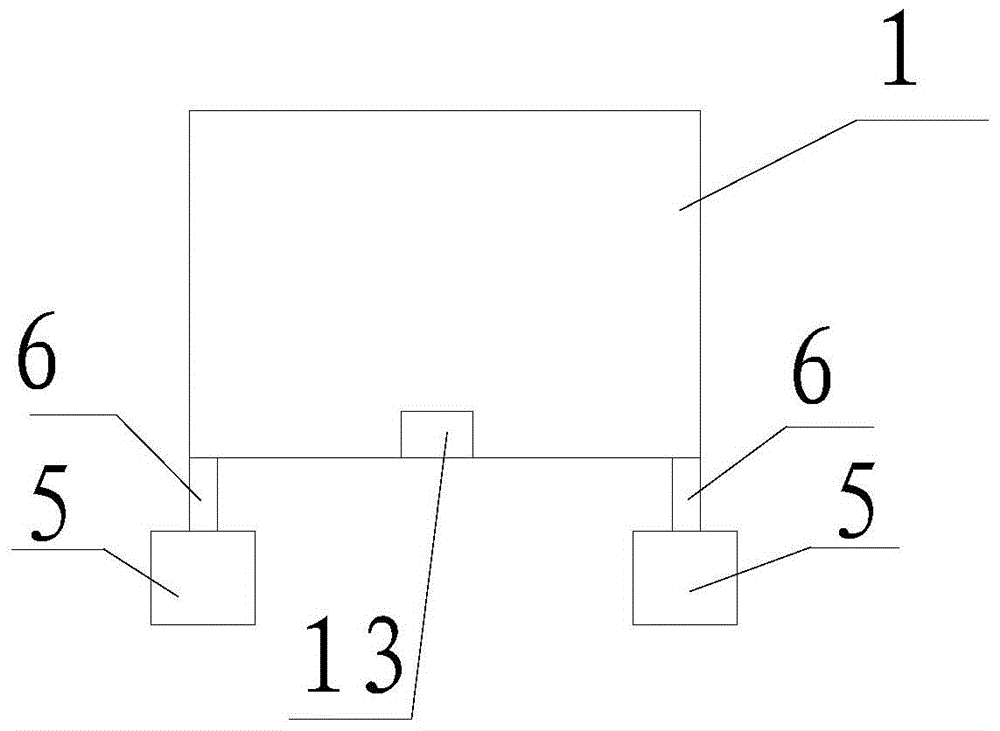

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0014] Such as Figure 1-3 As shown, a device for laser repairing a quartz crucible includes a laser device 1 and a feeding device 2, and the laser device 1 includes a housing 11 and CO disposed in the housing 11 2 Laser generator 12, housing 11 is provided with laser outlet 13, laser outlet 13 is a round hole, CO 2 The laser light generated by the laser generator 12 is emitted from the laser outlet 13 . The feeding device 2 includes a hopper 21 and a feeding pipe 22 connected to the outlet of the hopper 21. The hopper 21 and the feeding pipe 22 are integrally formed. The side wall of the hopper 21 is screwed to the housing 11. The hopper 21 can be used to hold quartz sand for filling. An on-off valve 23 may also be provided on the feeding pipe 22, thereby being able to control the supply amount of the quartz sand.

[0015] In addition, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com