A valve-type microfluidic two-component electrospinning nozzle

An electrospinning, two-component technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of capillary blockage, difficult to clean, complex structure, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

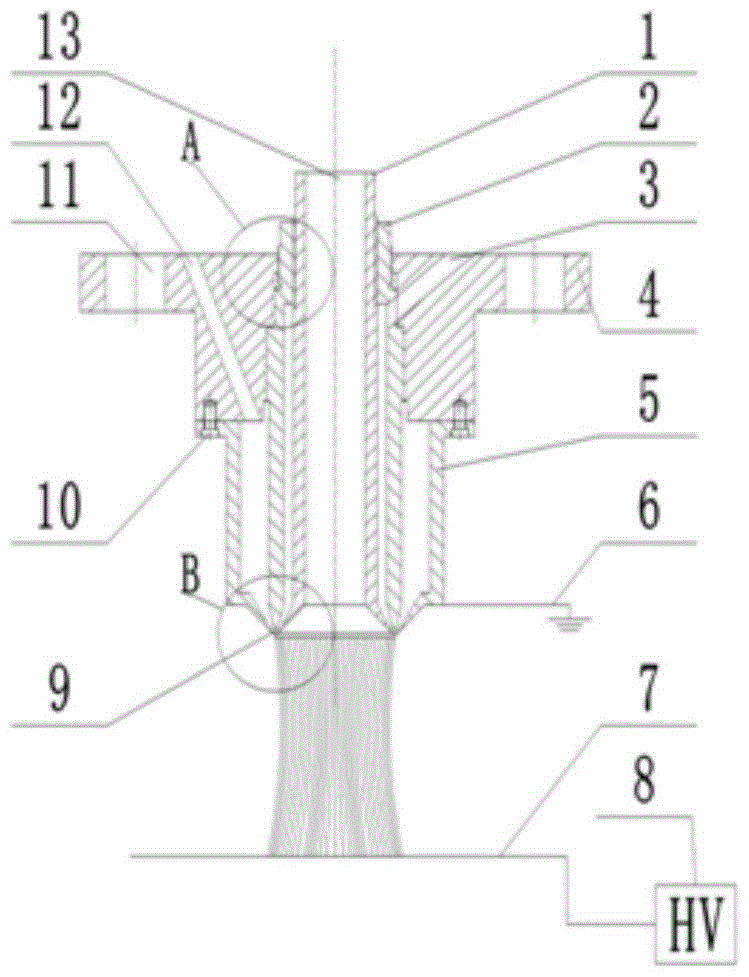

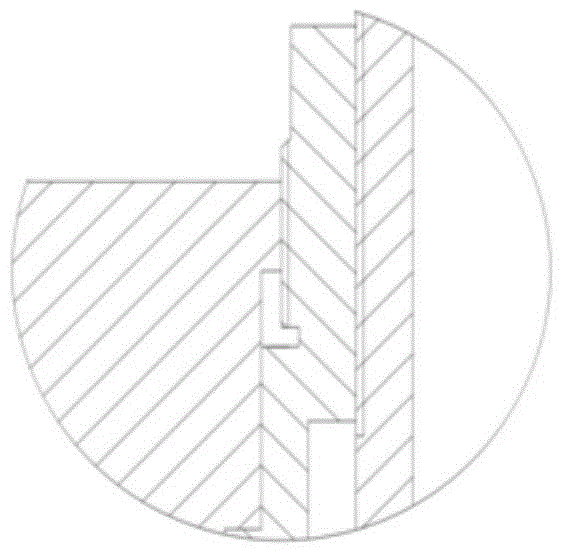

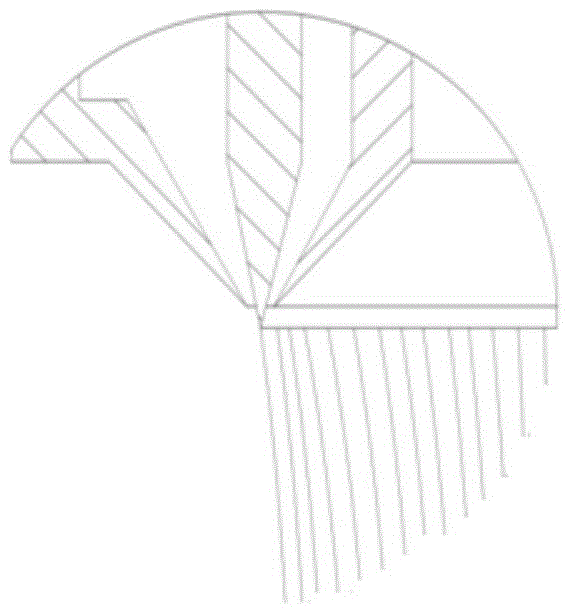

[0015] A valve-type microfluidic two-component electrospinning nozzle of the present invention, the schematic diagram of the nozzle is as follows figure 1 As shown, it mainly includes inner material cylinder 1, split column cylinder 2, inner material cylinder inlet 3, connector 4, outer material cylinder 5, grounding 6, receiving plate 7, high-voltage electrostatic generator 8, spinning tip 9 , a fixing screw 10, a fixing screw hole 11, an outer barrel feeding port 12 and an auxiliary air inlet 13. The inner material cylinder 1, the splitter cylinder 2 and the connecting piece 4 are coaxially connected through threads from the inside to the outside. It is connected with the outer material cylinder 5 by screws 10, the outer material cylinder is located under the connector, the outer material cylinder 5 is grounded, and the receiving plate 7 is located directly under the entire nozzle and communicated with the high-voltage electrostatic generator 8.

[0016] The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com