Two-stage beam shrinkage system based on photonic crystal resonant cavity

A photonic crystal and beam-shrinking system technology, applied in the optical field, can solve the problems of limited application, complicated gradient waveguide structure, reduced device integration, etc., and achieves the effect of small output spot, low loss, and improved integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

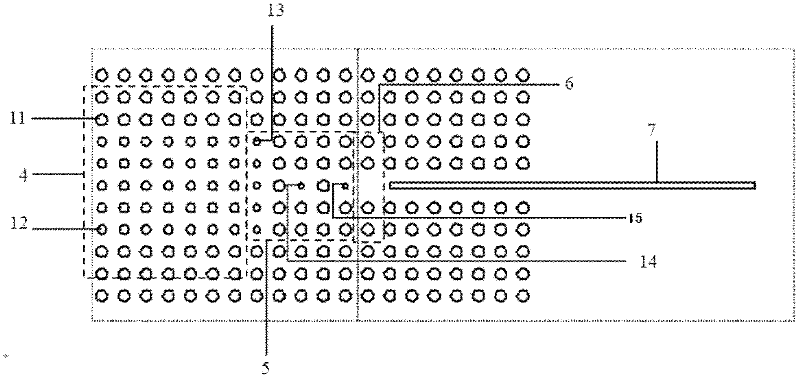

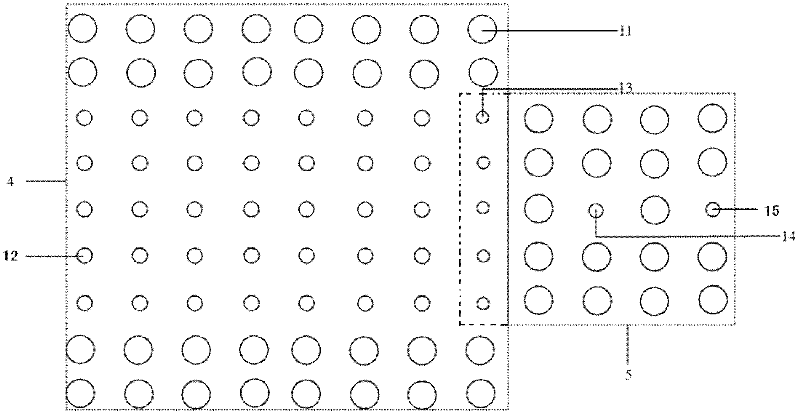

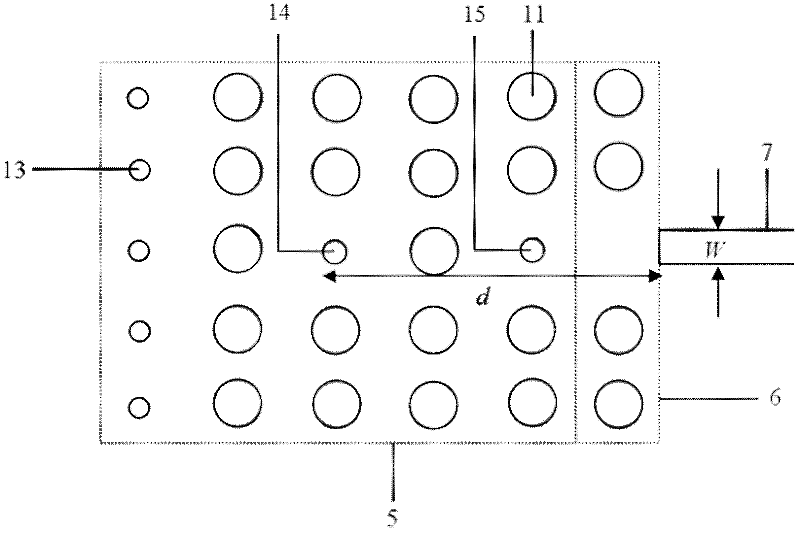

[0028] Such as figure 1 , 2 , 3, the two-stage beam shrinkage system based on the photonic crystal resonator of the present invention is composed of a photonic crystal waveguide 4, a photonic crystal resonator 5, a secondary photonic crystal waveguide 6 and a nanowire waveguide 7 arranged in close order; The primary photonic crystal waveguide 4 is a W5 type photonic crystal waveguide, the secondary photonic crystal waveguide 6 is a W1 type photonic crystal waveguide, the photonic crystal resonator 5 is formed by adding point defects 14 in the photonic crystal, and the photonic crystal resonator 5 and a A row of dielectric pillars 13 is distributed at the junction of the first-level photonic crystal waveguide 4, and the row of dielectric pillars constitutes a coupling region; the junction of the photonic crystal resonator 5 and the W1-type photonic crystal waveguide, and a coupling dielectric pillar 15 is distributed at a position corresponding to the point defect 14; the entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com