A fire door made of aluminum foam

A technology of aluminum foam and fire doors, which is applied in the field of fire doors, can solve the problems of bending deformation, bulky door body, inconvenient transportation, construction and installation, etc., and achieves the effects of convenient installation and use, cost reduction, and good sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

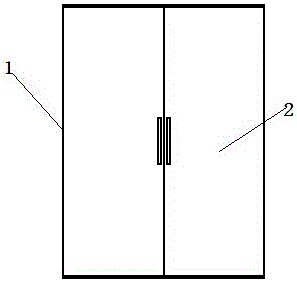

[0013] A fireproof door made of foamed aluminum, including a door frame 1 and a door leaf 2, the door leaf 2 is made of foamed aluminum material, and the foamed aluminum is made by the following method: a. heating recycled aluminum to 670°C to melt it; b. Add 5% (weight) silicon carbide particles to the aluminum liquid, the particle diameter is 15 μm, stir evenly c, pass nitrogen gas into the aluminum liquid, and stir the aluminum liquid at the same time, the speed of the mixer is 600r / min, d, for the aluminum liquid The temperature is lowered to solidify the molten aluminum to make aluminum foam boards, which are then cut into required sizes.

Embodiment 2

[0015] A fireproof door made of foamed aluminum, including a door frame 1 and a door leaf 2, the door leaf 2 is made of foamed aluminum material, and the foamed aluminum is made by the following method: a. heating recycled aluminum to 675°C to melt it; b. Add 3% (weight) silicon carbide particles into the aluminum liquid, stir evenly c, pass nitrogen into the aluminum liquid, and stir the aluminum liquid at the same time, the speed of the mixer is 800r / min, d, cool down the aluminum liquid, so that the aluminum The liquid is solidified to make a foamed aluminum board, and the foamed aluminum board is cut into the required size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com