Efficient coaxial air curtain dedusting system for coal mine

A dust removal system and high-efficiency technology, which is applied in dust prevention, mining equipment, safety devices, etc., can solve the problems of high content of toxic gas, large dust in operation flour, and dispersion, so as to achieve outstanding energy saving effect, prevent dust from spreading, and remove dust The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

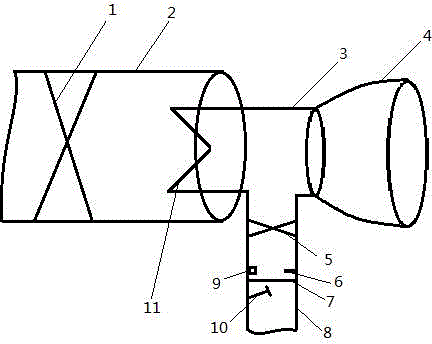

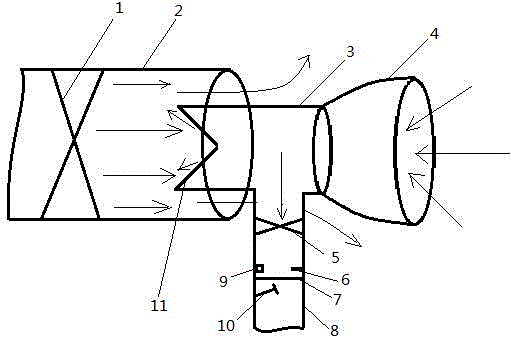

[0013] A high-efficiency coaxial air curtain dust removal system for coal mines, comprising an inner air cylinder 3 and an outer air cylinder 2, the inner air cylinder 3 has a trumpet-shaped opening, and the end of the inner air cylinder 3 with a smaller diameter is concentric with the outer air cylinder 2 without contact Socketed in the outer air cylinder 2, one end of the inner air cylinder 3 socketed in the outer air cylinder is closed, and the inner diameter of the outer air cylinder 2 is larger than the diameter of the smaller end of the inner air cylinder and smaller than the diameter of the larger end of the inner air cylinder. The outer air cylinder 2 is provided with a compressor 1, and the side wall of the inner air cylinder 3 is provided with an air outlet pipe 8, and the air outlet pipe 8 is provided with an exhaust fan 5.

[0014] Preferably, the inner air duct 3 of the present invention has a cylindrical air duct at one end and a trumpet-shaped opening at the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com