Rotor end surface temperature measuring device for traction type molecular pumps

A technology for temperature measurement device and molecular pump, which is applied to measurement devices, components of pumping devices for elastic fluids, non-displacement pumps, etc., can solve the problem of rotor deformation, the difficulty of processing molecular pump assemblies and the increase in assembly difficulty. , It is impossible to guarantee that the temperature measuring device can be replaced at will, so as to achieve the effect of simplifying the structure and ensuring the flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

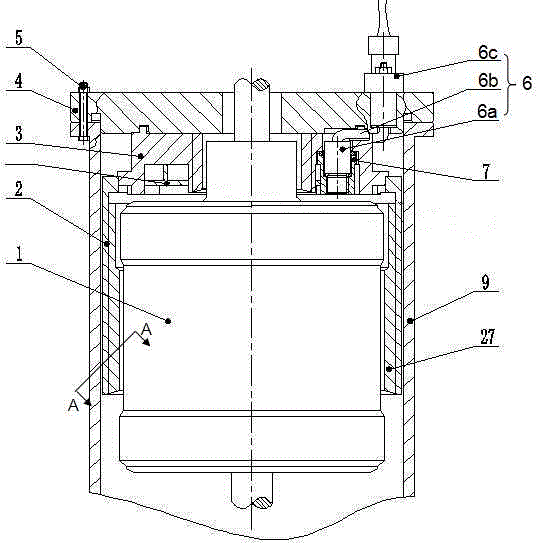

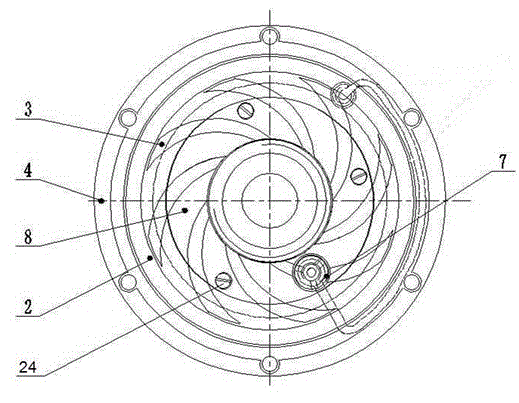

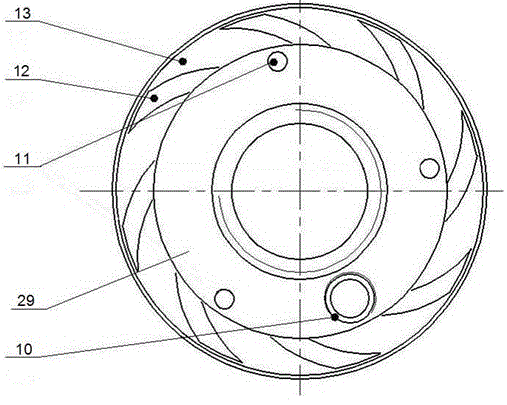

[0040] Such as Figure 1~12 As shown, a rotor end surface temperature measuring device of a traction molecular pump includes a cylindrical casing 9, a cylindrical rotor 1 is arranged inside the casing 9, and the end surface is fixed to the end surface flange 4 by bolts 5 inserted into the bolt holes 30, Inside the casing 9, on the periphery of the rotor 1, and coaxially with the rotor 1, a first-stage molecular pump 2 is arranged, and a third-stage molecular pump 3 is interference-connected with the first-stage molecular pump 2, and the second-stage molecular pump 8 is fixed on the second stage. In the three-stage molecular pump assembly groove 29, the inner wall of the cylindrical first-stage molecular pump 2 forms a helical first-stage pumping groove 27, and the lower end surface of the disc-shaped second-stage molecular pump 8 forms a plurality of evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com